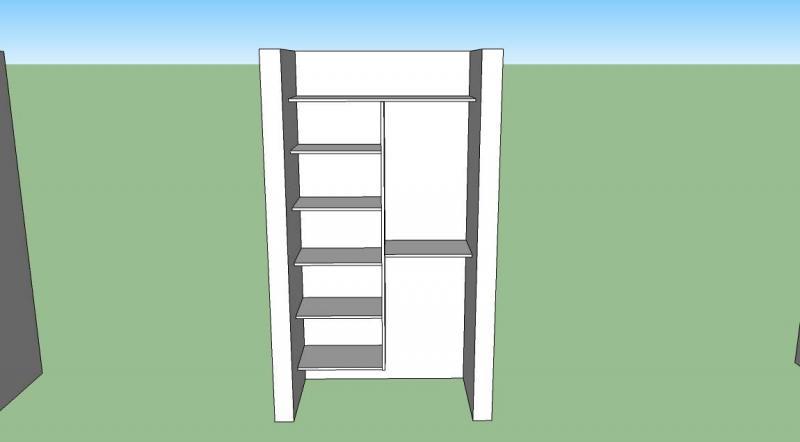

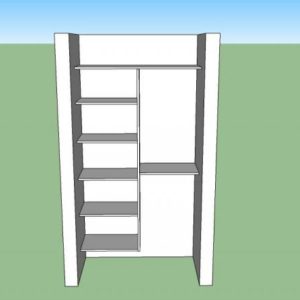

Attaching vertical divider in closet shelving…

I have 6 closets to do and was wondering what the best way is to attach the vertical divider between two sections in a way that is strong and gives support to the shelves. I see them installed by new contruction finish carpenters but haven’t done it yet myself. It would be something like this… I’m using raw PB shelving. I’m most interested in how new contruction finish carpenters tackle these.

Replies

Also if anyone could instruct me how I can change my user name to my actual name that would be great. I just became a member about a month ago and can't find anywhere that will let me change it to my name.

spencer

There should be an "EDIT" button in "My Profile" (yours).

That will open your email registered address and your name etc................

See if you can get there and change the name (if might not let you as I remember a long time ago b/4 this site was "improved", that the then tech guy Mark had to get me my name back...............)

or

Let me know the name you want to use and I'll try..................and if lucky-that might work.

PM me or put it in this thread and I'll hopefully come back and read it.

I'd run the divider to the floor. Running the top shelf continuously provides a lot of rigidity, as does tying the divider to the wall cleats.

What Andy said is how most finish carps would do it.

Depending on how far along you are, and what kind of access you have to what's behind the shelving, you can always add blocking behind the verticle piece and pocket screw it into the backing with some construction adhesive.

If it's bare particle board you're probably not working in the price range that makes adding a plywood back feasible.

I'm not entirely clear why you wouldn't run the verticle to the floor, especially with PB to work with.

For some reason I have it in my head that the new contruction trim subs weren't running them to the floor. I must be wrong as they don't do anything that takes extra time/effort.

My reasoning for not running them to the ground is two fold:

1) If you run them to the floor you have to lay your carpen around the divider. This creates a problem if the HO wants to ever tear out the current closet configuration and replace it with say, something more open. You would have a big ugly cut right down the center of your closet.

2) I think keeping the divider up 12-16" off the floor creates a more functional storage space with more flexibity. This is just personal preference.

Point number 1 is the main reason. I also want to know because I'm considering getting more into working as a finish trim sub on new construction and need to get my technique dialed in for cranking them out as quickly/efficiently as possible.

This is how I'm planning on doing these closets.

There will be one fixed section that will be installed first. It needs two fixed shelves + the top shelf which will fix the width. This will allow the shelves in between to be adjustable. I'll drill holes for 1/4" pegs. This section will be screwed into the wall on one side which will give it plenty of strength.

I'll use 2x4 cleats on the wall horizontally. They will be screwed to the studs and placed directly under the fixed shelves. I'll then install the remaining side to the wall giving special attention that the width in consistent the whole way. This is tricky because of the drywall mud buildup in the corners. Fixed shelf on that side will be fasted with some metal L-brackets on the underside.

I think this will be plenty sturdy.

If the two 2x4s are solidly attached to at least two studs, and if the center partition is solidly attached to the 2x4s (ideally notched to fit around them) then that should be sufficient for any ordinary shelf. If it were to be used for books or other heavy items I'd double up the fasteners.

"spencer"

The name change worked-I think.

2x4's as a ledger is way too thick.

You can get by with more of your melamine or at least something else-3/4 thick.

Your joining techniques are of utmost importance. Particle board is a tough thing to fasten together.

Ledger under the bottom-sit the sides upon that bottom.

Yeah, if I were doing it I'd use 3/4" plywood for the ledgers, or maybe use some of the scrap pieces of MDO I have in the garage. Whatever I had handy, so long as it was something better than flake board.

Another option would be to screw a 1x4 flange to one side of the center divider, then locate the divider so the flange is over a stud. Screw the flange home, and proceed normally.

The vertical either must rest on the floor, be attached to a (fortuitously placed) stud in the wall, be tied to a full or partial back for the shelving, or be tied to some sort of rigid cross-member (perhaps some sort of a steel plate attached to the back wall). It's not sufficient for it to be supported by one or two standard shelves.

Most "generic" finish subs

Most "generic" finish subs don't do anything extra - including worrying about the carpet guys or how homeowners will use the space. They will be following plans that spell out exactly what it should look like and your job is to get it build as quickly as possible given the expected quality level seen throughout the home's trim package. In general sheetrock screws, 15g trim nails and glue are about as technical as most shelves get.

Many of us are, or have been, finish subs. Everyone has to do what fits their strengths and weaknesses, but don't expect to get rich with blow and go finish work. Come to think of it I don't know of any rich finish guys! lol My plumber, HVAC guy, and electrican all make better money than anyone running a finish outfit that I've come across.