Hello All,

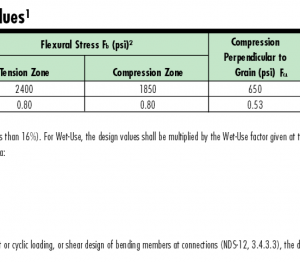

Can anyone show me the correct way to figure out the actual strength differences for a rosboro treated X-beam glulam 3.5″x9.5″x20′ and a 3 ply #2 treated 2″x12″ beam? I have attached some information on the glulam beam. I am curious to see how much the strength differs. I currently have 4 – 3ply 2×12 beams for a full cantilevered deck.

Thanks

Replies

Need to know the span, the

Need to know the span and the amount of cantilever. What do you want to know about the strength: uniform loads, point loads, how maximum loads compare?

Reply

mike mahan wrote:

Need to know the span and the amount of cantilever. What do you want to know about the strength: uniform loads, point loads, how maximum loads compare?

How much of a difference a glulam woulkd make in my sutuation. Catlievered 8ft right now, with a 20ft beam overall. I want to replace the bent one for good measure. These are about 30 years old.

Spacing

What is the layout of the beams i.e. the tributary area.

I think that the 3 2x12s are going to prove stronger due to the extra depth.

mike mahan wrote:

What is the layout of the beams i.e. the tributary area.

I think that the 3 2x12s are going to prove stronger due to the extra depth.

Do all the strength comparisons you want, heck check steel box beams, I say put a post under there.

"8' cantaliever"? On an exterior beam? Are you freakin' nuts? This is a disaster waiting to happen. I see details like this and shake my head. Did somebody think they were going to outsmart gravity with the cantaliever and mother nature with that little cap over the endgrain of that beam(s)?

"Don't want to add posts"? "Want to keep unobstructed access?/Views?" No matter. Do it.

an 8ft cantaliever is one hell of a teeter toter! You have to start the question not only the beam but the massive load being put on the fulcrum point at the foundation and the massive upward force being put on the opposite end of the cantaliever. You're putting a very fat kid way out from the fulcrum point and its going to take a whole lot of weight on the other end (all exceptionally tied together) to keep that fat kid in the air. Normal construction at the interior end isn't going to be enough. You would have to have a way to spread the upward force over an extensive area or find some way to tie the interior end to the ground...not unlike a huge bridge abutment with all its weight counter balancing the bridge hanging out over the water.

Assuming the beams are 8' oc., the glue lam is undersized by 600% and the 3 2x12s are undersized by 300%. You'd need a glue lam 20 inches deep or 4 2x16s.

Math

Mike,

Thanks for your input, could you show your math for figuring this out? Also, what psf load are you using? Could flitch plates be an option?

-JF

Beams

Beam design works by trial and error. You don't plug in requirements and get a beam size. You plug in beam sizes and get a yes or no.

Beam 1 = the gluelam you specified

Beam 2 = the solid 2Xs you specified

Beam 3 = the minimum gluelam that works

Beam 4 = the minimum build up 2x beam that works

See the first image. span.jpg

The span supporting the cantilever is 12' with a tributary area of 8' (as if they are 8' oc). Uniform load of 50psf. (These calcs come out the same for a restrained beam with no load on this part of the span.)

The cantilever is 8' with a tributary area of 8'. Uniform load 50psf.

See the image calc.jpg to see the pass/fail specs on the various beams.

Sorry, but I can't share the software.

I don't think you've got any good option other than posts. Doubling the number of beams doesn't help that much. Normally a deck cantilevers on joists that are 16" or 24" oc.

Mike, Wow, that is some

Double Post

Mike,

Wow, that is some great software you have there, can you share the name? Do you have the ability to do I-beams in the software? If i am stuck with the opening from the house at 11.25"x4.5" that limits the beam sizes. What if we moved to a steel beam such as a W10x49?

Thanks -JF

I've never done much with steel, but I ran the calcs. In order to keep under 11.5 depth you'll need three 1/2 flitch plates or a C10 30. The software doesn't do other shapes easily. You've got a lot of issues with restraint and bearing. Time to talk to a real engineer. I only use software for basic design then I take it to an engineer and tell him what I think will work based on the preliminary calcs.

Good luck.

Mike, Thanks for your

Mike,

Im going to run a quick beam deflection calulation, using cantilever uniform load, assuming each beam takes 1/4 of the entire load, is this correct? W10x19 Beam

Load*Area

60PSF * 230ft = 13800lb/ft

13800lb/4 = 3450lb/ft per beam

3450 lb/ft = 288 lb/in

Max Deflection = (288*96) / (8*29000000*96.3)

Max Deflection = 1.093 inch - Fail not lower then 1/360 of 96

-JF

Where'd the picture go?

I always thought beam strength was inversely proportional to the square of the distance from the source.

Mike,

Drew this up in CAD for a better representation,

Outside beams cantilever 8 ft, while inner beams canilever 5 ft.

I am now trying to figure out the load on each beam, using the area reference in the attached picture. Is this correct?

If so, then the see attached excel picture.

-JF

here ya go

see attached.

Do you know the math behind generating the %'s for Area, Ix, and Sx? Id like to build it into the excel spreadsheet.

Would I be able to purchase the software you have somewhere?

-JF

http://www.archforms.com/

Mike, Thanks for the link,

Mike,

Does the beam actually see any load on the inside of the house? I ask because there is cinderblocks under the beam for that whole legth, im under the impression the beam is not under any load, as any force put on the beam will be applied in the opposite direction by the blocks, so it would be equalibrium. Therefor it would not be loaded like a simple supported beam, and the only load would be on the cantilever.

Thanks!

-JF

Of course, there are cantilevered bridges with about a million tons of concrete for a counterweight. They don't need to observe the "one to three" rule.

and I noted that in a previous post. The bottom line is its not just about the cant being supported its also about the magnified upward force that is placed on the interior portion of the beam past the fulcrum point. Having a cinder block wall underneath the beam does nothing unless the beam is correctly tied to the wall and the wall correctly tied to the foundation....and even then the weight of that wall and foundation may not be enough to counteract the multiplied upward force placed on the beam.

Most times you can overbuild something cheaply enough that you don't need to worry about it. But this case is definitely a trip to engineer land.

Pictures

Here are the pictures for how they are ancored in the house. I plan on reducing the cantilever down to 6ft. I have not seen any decking cenilevered like this before. The beams all have 12ft of block under them, the outside beams hold up the second level for the first 12ft of the house, the inner beams have 4-5 ft of house over them, seen in the pictures.