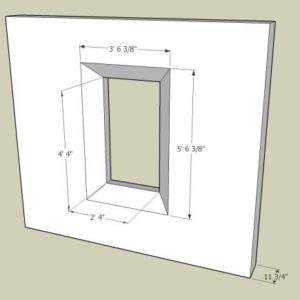

Bevel surround for the ICF wall window

I’m looking for a way to dress up a bedroom window in a lower level with ICF exterior walls (Logix ICF at 11-3/4″ total thickness.)

The “buried look” you get when doing a window in a thick wall like that is something that doesn’t sit well with me.

Over at our church, all the exterior windows have a beveled surround, like you see in cathedrals and all other buildings with thick stone walls. Much better for the light.

So, I dreamed up one for an opening in an ICF wall. Here’s the look.

I am thinking through the details, but I always tend to overbuild. If you have done it, describe in words, or better, with photos, how do do it quickly and easily.

The walls and returns are to be sheetrock, the trim is to be determined.

Replies

Gene - interior or exterior bevels?

We love our deep window sills, but though of recessing the windows to the interior to give the stone cottage look on the outside. Most of my thoughts were along a split window buck theme, removing the outer piece after the pour. Would you bevel to the foam depth, or are you looking for something deeper, getting into the mud?

To the inside, of course. I was really inside the church when I thought of this! ;-)

What I am thinking, is making the bucked opening in the ICF at least as big as the extent of the beveled limits, then wood-framing a sheathed "sub-opening" for the window within it, using 2x4 framing and 7/16 OSB on the outside, then throwing in some 2x bevel rips, appropriately spaced and positioned, on the inside, to pick up the sheetrock returns and trim.

We would use sprayed-in PU foam all around to pack out the surround and seal the whole thing up, before sheetrocking.

I like it. One other thought is you could pre-bevel the forms and apply plywood before the pour, putting foam sheets in for a thermal break.

Any way you do it it will be time consuming, but that comes with the (custom) territory. Its definitely worth doing!

Treat every person you meet like you will know them the rest of your life - you just might!

Gene,

I"ve been looking for a way to that for a reasonable price for years with no success to date.

I wouldn't like to try angled forms. It feels to me like an invitation to bulging or blowouts.

I think the best chance of success might be found in using a window buck which fits inside the form in the cavity (and is heavily reinforced before the pour) or with the use of vinyl bucks like the bucksaver from Arxx. That way, the inner foam wall and part of the buck could be cut out afterward without too much pain.

It would be easier to leave a few inches of drywall extension square to the window before beginning the flare, too, so that you wouldn't have to deal with the concrete and you could begin the job at the channels on the windows. Easy, maybe.

If you're cutting through the 2 3/4" of foam plus part of the buck, then you'll have to use a recip saw. The cut would be up to 4" deep and would show as about 6" on the flat of the finished flares.

The flare itself could be fastened to the wall drywall by inserting one side of a 45 degree sheet metal angle behind the wall drywall and screwing through it, leaving the other side of the angle for fastening the flare to. Quicker than woodwork. You could do the same thing at the outer knuckle of the flare, though it would be a bit harder in that both sides or that joint would be partially floating.

Anyway, I have thought about this but never found anybody who wanted to pay me to try it out. What do you think?

Ron

Gene,

Ron and I have talked of this b/4. I did the flaired openings in our house because the lower level wall thickness is maybe 10'', the upper floor framing-2x6 plus. Primary reasoning was that being at least passive solar in construction, why limit the Width of the openings allowing the sun in as it makes its way across. A straight return would do that. Also, the viewing area would be cut down on anything but a straight on shot.

It makes for a dramatic series of shadow and form lines.

Here might be a couple shots of what I'm talking about..........if successful in hunting them down.

Here's one of the lower level and I'll take one of the upper arch top returns tomorrow.

View ImageA great place for Information, Comraderie, and a sucker punch.

Remodeling Contractor just outside the Glass City.

http://www.quittintime.com/

I think I'd bevel the sides as shown, but keep the top and bottoms horizontal.

Gene, I've done a bunch of these, and they are pretty easy and not at all expensive.

I wish I knew how to draw this for you. One sketch would say it all.

Draw the window in section as if it were installed in the wall so you can see the bevel you are looking for. Draw in your rough buck and nailers for the window (I'm assuming these windows have nailing fins) and situate the window in the depth of the wall anywhere you like.

Now you will know what kind of angle you are dealing with in front of and behind the window. At that point determining the actual opening size is as close as the TAN function on your calculator, or use your Construction Master. Heck, you could even scale it.

I have had good luck making rough bucks out of regular framing lumber. I spray them dowm with an acrylic water repellant and wrap the side facing the concrete in Grade D building paper before installing them so there is no concrete contact. I suppose peel & stick membrane would be good if you had extra. A few countersunk carriage bolts holds them in the concrete real well.

Brace the bucks vertically and horizontally with 2x4 scrap, a few scraps of plywood on the corners keeps them square.

Build them oversized enough to accomodate the angles you drew in section, after the concrete is cured a few days strip the braces out and scribe a line where you want the windows to be in the depth of the wall. I have been able to use up almost all of the scrap on the job packing the bucks out to finished size. Running some of it through the table saw set at the right angle saves a lot of work. A judicious application of OSB scrap and you are done.

It's not structural -- it just needs to be strong enough to hold the window. It's OK to use scrap. I use full-length pieces where I'm actually nailing the fins so everything stays strong and square, but everything around that can be whatever.

If you think about the angles like you were framing and sheathing a valley on a roof (just a real lot smaller) it will all be clear.

So when you are done cover it all in peel and stick membrane, pay the same atttention to the drainage plane as on any other house.

When in doubt, make the opening in the ICF a little big rather than a little small.

Whether the method shown in these cartoons came to me in a dream, or a hallucination, I cannot recall. In any case, I am probably overthinking it.

The opening is made in the ICF wall for the window, using what I call the "center plug" method. The product we'll use is LOGIX 6" core, which actually has a 6.25" concrete core, and an overall thickness of 11.75" In the center plug opening method, we rip PT ACQ lumber to 6.25" and cut lengths to plug and fill the 4 sides, and brace it all for the pour. Some HD galv lags are placed in the plugs to suffice as anchors.

Then we use some SPF framing lumber, and using a combination of bevel-ripped parts and straight cuts, we make this.

Inside view.

View Image

Outside view.

View Image

It takes a rip added onto a piece of 2x12 to make the wide sill part. Note the 1-1/2" offset.

The kit of parts goes into the opening, the four surrounds first, with them screwing into the PT ACQ opening plug surround, then the inner window receptor kit goes in, toe-screwed to the surround frame.

Outside view.

View Image

And inside.

View Image

The outside face is then faced with 1/2" OSB as shown, and the cavities are shot with sprayfoam on the inside. The window is then installed, flange-fitting to the wood subframe. It is not shown in these pics.

View Image

Note that we still have 1" of recess.

We then glue and screw on some 1" styrofoam on the outside, bringing it flush to the ICF face. We'll later do a buildup of 1" styrofoam all around the window to case trim it. Everything gets a synthetic stucco finish on the outside. The top surfaces of the head casing and sill get 5 degree bevels. The built-up styrofoam surround is wide enough to completely cover the wood sill part seen in the pic above. If we want to use a narrower foam casing kit, we would notch back the sill and carry the OSB down over it.

View Image

On the inside, the beveled surface of our subframe parts give us a nice laydown for our 3-sided sheetrock treatment.

View Image

The finish wood trim inside is a small beveled strip covering sheetrock edge at jambs and head, with the jamb trim parts sitting down on a beefy sill with a bullnosed edge, small horns with returns, and a small beveled strip lip underneath.

Man, I wish I knew how to draw like that on the computer.Just my opinion, yes, you are overthinking this a bit and maybe still using too much relatively expensive material.But the biggest problem I see (if I read you correctly) is the rough buck itself. You need some restraint on the cut part of the foam at openings to prevent a blowout.Typically this is why there is a full-width buck -- so you can put removeable and temporary flanges around the edge of the buck. They keep the foam from spreading.I have had ICFs blow out even with the flanges in place (ICF was defective, a web was not cast in completely). The pressure can get right up there sometimes.As for your window splay, these full-width bucks actually help, because the foam cutout is just 3" bigger each way than the buck, so you have a nailing surface all the way to the edge.Maybe someone here who can draw on the computer will jump in.What it comes down to is that openings in ICF are expensive no matter what, more so if they blow out. I know I keep saying "cheap", but that's a relative term. You want to make it as fast, cheap, and safe as possible. I throw $150 to $175 labor and material at each opening if they are as complex as your two-sided four-way splay, and I think that covers it just fine.

Edited 1/28/2007 10:13 pm by Catskinner

A detail from Logix, showing the inside-the-cavity buck. It is crossbraced just like a full width arrangement. Heck, if you don't trust it like this, you can screw another buck assembly, this one with big full width boards, inside, then after the pour, unscrew, and you'll have the inside plugs left.

Whatever material expense there is to this doesn't bother me too much. The plan only has one window opening in the foundation, and it is not large.

View Image

Edited 1/29/2007 12:17 am ET by Gene_Davis

Gene,

Like Catskinner said, the insert type buck needs some serious reinforcement before the pour. You can hold it in place temporarily with fiber tape wrapped tightly from the outside face to the inside face. Before the pour it needs to be really fastened. I recommend using 1/4" x 5" lags with washers through 1 x 4 from outside and inside into the core buck. Then you add bracing vertically and horizontally.

Your solid sill form doesn't leave anywhere to pour into the cavity below the window. You want to be able to go around and pour into the cavity below the windows first. The benefits are that you know there are no voids or honeycombing there and there's that much concrete you haven't had to drop through all that webbing and steel from the top.

Also, check with whoever you've got lined up to do your synth stucco about those nailing flanges to see if they will be able to stucco over them. The stuff doesn't stick real well to vinyl. On the other hand, strapping the windows in to the house with steel straps, will work fine.

Ron

My assembly of sticks goes in after everything is poured and cured.

For the formwork and pour, we'll do as the Logix diagram shows, doing solid 1.5 x 6.25 "plugs" at sides and top, and the multi-piece plug makeup at the bottom with the opening for pour and venting.

To fix it all and brace it, I thought we would use 15" rips of 3/4 CDX at the sides and top, each of the three parts with 2x4 rims wrapping and screwed to the Logix, and then center braces each way to block the whole thing. That still leaves the opening at the bottom. Note the 1x members in the Logix drawing that tie the bottom plug to the wallforms.

When done and cured, all this stuff comes out, leaving the 6.25 core plugs of PT ACQ in place on all four sides.

Then all the stuff shown in my pic sequence goes into the opening.

Edited 1/29/2007 9:52 am ET by Gene_Davis

Gene,

I get it. It will probably work just fine.

You should still think about using sheet metal angles bent 45 degrees for the inside angles. You could dispense with both sides and the top of your outer frame. You can add your foam to the outside with expanding foam for adhesive. You don't need wood to nail the foam to. You would still need your inside frame of course to fasten the window to.

Save some time, some money and some hassle.

Ron