With all the discussion on ridge beams lately it got me thinking?

I understand the difference between ridge board and ridge beam. It’s the Ridge beam and rafter connection I’m trying to learn something about.

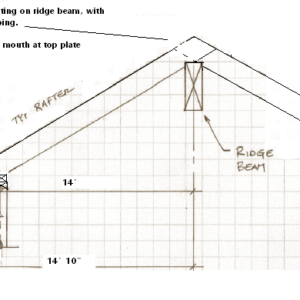

(See attachment )

I have seen a technique where the rafters are notched to sit on the ridge beam and overlap each other, with a traditional Bird’s mouth on the other end of the rafter sitting on the top plate.

This type of detail seams as if it would be extremely strong and relatively simple to do. My contractor buddy say’s it a detail borrowed from timber framing but no one uses it any more.

I have goggled and searched all over the place with very little luck.

Can any one help me learn the finer points of this detail? Links or tribal knowledge are welcome.

Thanks

Bill

Replies

I'm not sure what specifically you are looking for. Your drawing pretty much shows it as it should be. Nice drawing by the way. Here is a pic I took a couple of months ago http://pic9.picturetrail.com/VOL293/2163851/4541023/118330358.jpg I don't have any closer pics, but the beam is a 5 1/8" x 18 glulam that clear spans about 22 or 24', I forget now. That is a 12-12 on the left and a 4-12 on the right. I didn't get any pictures when it was done, but you can see that it is done basically the way you drew.

Nice van!

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

I'm not an engineer, so I am only assuming when I suggest that such a ridge would become structural and load bearing. It might require additional support from below at various points depending upon span.

As for why it's not prevelant, I'd suggest it's a good deal more time consuming.

You're also staggering the rafters which would mean doing the same with the supporting framing members.

My 2 cents.

J. D. Reynolds

Home Improvements

Not anything wrong with that. It satisfys all the requirements for attahment and bearing.

It can use less material - in a situation where the luimber is barely long enough - to butt them together with plumb cuts at center of beam instead of cross lapping them, but then a metal strap would be needed to prevent uplift hinging

BTW, for future ref, save your drawings for posting as Jpeg or GIF format if you can. That makes for a smaller file size.

Welcome to the

Taunton University of Knowledge FHB Campus at Breaktime.

where ...

Excellence is its own reward!

Bill,

That's the way I've been doing it for years and still do it. I drew this a while back.

Tim,

Thanks for the pic, I can't take total credit for the one I posted, found a drawing on the net and adjusted it a little. Are you using 2 x 10's for the rafters?

Are you "upsizing" the rafters to compensate for the material lost by the notch?

JDRHI,

I'm no engineer either. In this particular case the ridge beam would be 29' 6" with support down to a block wall on each end and a center post, rafter span would be roughly 14'.

And I will get some real engineering if we go this way. But I'm guessing it would be a triple 2 x 10 at least.

I would be staggering rafters, but I don't follow you on the " which would mean doing the same with the supporting framing members."

Piffin,

Thanks, that was my first ever attachment, I'll try to figure out Jpeg.

Joe,

are doing conventional framing? Do you still use collar ties in this application or would nailing or bolting the rafters together at the overlap do the job?

Thanks every one!

Joe,are doing conventional framing? Do you still use collar ties in this application or would nailing or bolting the rafters together at the overlap do the job?Yes, I'm doing conventional framing. No I don't use collar ties in the situations I've framed before because all those beams are structural and they don't need collar ties.Nailing the rafters together and nailing to the top of the beam is standard. Using bolts means nothing as far as wether or not you need collar ties or not. That beam you plan on putting in I think in one of your posts you said was about 28'. If so you'd better plan on having that beam Engineered because that's a very big span for a beam without collar ties.If you don't want a beam and want to have collar ties because you like that clipped ceiling effect. Then your collar ties will have to be Engineered and placed at the right height so that you can just use a ridge instead of a beam.Joe Carola

Joe,

that beam will be about 29' long but also with a center post down to footer so I'm really splitting it in half. Please no worries, I WILL be getting engineering for this project, also I will need a real carpenter. I make a little furniture and I have some building skills, but framing a roof is a little out of my range at this point. .

Just to give you an idea of what I have in mind this roof will be covering my wood working shop. Currently the building ( 28' x 28' block construction) has a flat roof with a very small pitch front to back, and it's built in such a way that roof truss's or a ridge board with collar ties would be a lot more work / demolition / reconstruction than I want to do. That's why my interest in the ridge beam. I want to leave most of the old roof in place and cover it with a roof that will basically support it's self...

This project is a good ways off, but it's never to early to learn a little something.

Thank you and the others for your help!

That's what I love about this place

I like that detail, for a few reasons, but no one has mentioned blocking yet. I'd definately block...I guess along the top of the ridge beam so one set of blocks would do the job.TIPI,TIPI,TIPI!

That is all vaulted in that bonus room so its 2x10 and insulation. We typically pick one rafter stock size for a house and make all the rafters that dimension. I use such a small seat cut (2- 3 1/2") that I don't have to worry about over notching.