It’s fairly rare that I ever actually SEE a house that I’ve worked on. I probably see on in 50 that in the framing stages, and one in 500 that are completed. Someone emailed me some pics of a finished house yesterday, and I thought I’d post this so y’all could see it.

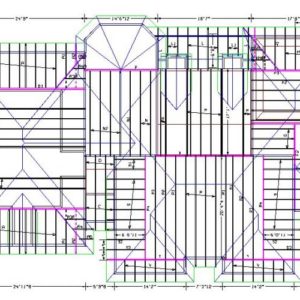

The first pic is a screen shot of the roof truss layout. There are about 200 trusses on this particular house.

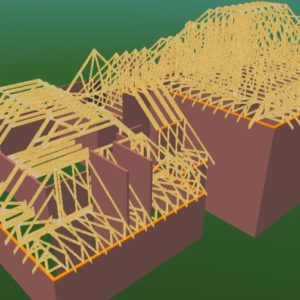

The 2nd pic is a 3D view of the trusses with the design program in “virtual reality” mode. It’s nice to be able to see a job this way, so you can tell if one of the trusses doesn’t line up with the others or something. It’s maybe a bit crude, but still pretty cool.

The last 2 are the pics that were emailed to me of the finished house.

Naturally, the trusses were all so well designed that everything fit utterly perfect.

(-:

Bureaucracy is the death of all sound work [Einstein]

Replies

Boss,

Thats a Nice looking house. Nice roof lines, The Boys in the BT Raffters Club need to take note of that roof!

Boss,

Thanks for the pics. That 3D pick of the trusses is slick! I always wondered how you guys could design trusses for such a cut up house. For some reason I didn't think that the 3D program was that detailed. Thanks for posting.

A set of trusses like that freak me out. Easier for me to visualize it stick framed :-)

What was the truss package in $ if you don't mind my asking?

"That 3D pick of the trusses is slick!...For some reason I didn't think that the 3D program was that detailed."

I can save those things as a VRML file. (Virtual Reality Modelling Language) Then you can twist and turn it around on your screen any way you wish. But you have to download special software to deal with the files. I can post the VRML file if anyone is interested in trying it.

"A set of trusses like that freak me out. Easier for me to visualize it stick framed"

Actually, this house was designed for stick framing. But virtually no one around here stick frames. So I had to redesign the whole structure from the roof down to the foundation in order to convert it. Lots of beams to take out, add in, and re-size.

And - Of course - They changed several things from the print that had to be worked into the thing. I probably have over 40 hours in designing this job.

It would have been tough to stick frame, too. There were so many places that the roof planes had to line up from one floor to the next. I figure that would take some time and head scratching to get it lined out.

"What was the truss package in $ if you don't mind my asking?"

I don't know for certain - I'm not allowed to price stuff in this company. But I'd guess somewhere around $15,000. Lots of odd setups, and the attic trusses over the garage are expensive.

Sex is a part of nature. I go along with nature. [Marilyn Monroe]

>> Actually, this house was designed for stick framing. But virtually no one around here stick frames. <<

Around here in NC it's different. Stick framing is nearly as common as not - especially if you subtract out the national builders who build street after street lined with vinyl boxes. Large custom homes are nearly always stick framed.

I'd think with a complicated truss roof like that, there would be a lot of room for a mistake in the truss design/production or other prob due to whacked foundation, etc. I'm guessing that it would be the kind of deal where the foundation is built and then someone from the truss company comes out to measure... which would help a lot. That's an advantage to stick framing - on the fly "adjustments" are often no big deal. On the other hand, if you don't have the crews with those skills, it cuts down your options.

"Around here in NC it's different. Stick framing is nearly as common as not"

I've learned here at BT that it varies widely from one place to the next. I think in the south there tends to be more stick framing.

Nationwide, I've heard that roughly 60% of all new houses use trusses. (Can't remember where I heard that, though)

I think it also has to do somewhat with how prints are drawn and/or house styles. The houses that are built around here are typically designed so that stick framing would be impractical. But in other parts of the country the opposite is true.

"I'd think with a complicated truss roof like that, there would be a lot of room for a mistake"

Yup - And I've made every one you could imagine. (-:

After a while all the numbers start looking the same. You can look at something over and over and not realize it's wrong. But if you make something 23' 4" instead of 24' 3" it's not gonna fly in the field.

It seriously *IS* hard to get every detail right. To get an idea of what it's like, think of this: You have to pre-design ALL the stick framing for a house. You get a print, but there are several changes. And the foundation is off.

You have to lay out every cut for every piece so that it can be done by some 20~ YO guys in a shop that you will probably never talk to. And they aren't terribly bright, so it has to be spelled out clearly.

Then you have to do a layout that shows where every piece goes. And the framer who will eventually assemble it will be someone that you've never met and may nevre talk to.

And all that has to be done fast and cheap. They want it doen NOW so they can get this thing under roof.

The plant guys won't be happy with something or other that you did. And the framer won't either. At some point the framer, GC, and/or HO are likely to change their mind about something and you'll have to revise part of it.

Then after all that, if there's a single mistake you're a moron and they'll cuss you for weeks.

No pressure. (-:

"I'm guessing that it would be the kind of deal where the foundation is built and then someone from the truss company comes out to measure..."

We probably measure about 2/3 of the foundations that we do trusses for. Sometimes the builder will square it up and tell us what he wants. Other times our salesmen will measure them. That certainly helps reduce problems.

"That's an advantage to stick framing - on the fly "adjustments" are often no big deal. "

You're right on there. There are some cases where a truss can be made "adjustable". But for the most part you're stuck with what ya got.

"On the other hand, if you don't have the crews with those skills, it cuts down your options."

It's all in what you're trained for and used to, I guess. Framers who always stick frame wouldn't do trusses well. And the opposite is true also.

Actually, it would be interesting to work with a stick framer for a while just to see how they do things. But since no one around here stick frames I likely won't ever do that...

I rely on my personality for birth control.

I'm guessing that it would be the kind of deal where the foundation is built and then someone from the truss company comes out to measure...

Guyatwork, around here the trusses are built from the plans, often before the foundation is done.

Complications arising from improper foundations are very rare. In most cases, the foudations can wander several inches and not affect the trusses. I've had some rare situations where I had to add a bearing header because the trusses were 4" short, but that type of mistake occurs when there is a mixup regarding exterior wall finishes (brick vs siding). In most cases of wandering foudations, the trusses end up hanging over an inch or two and since we always have a closed cornice, no one notices, nor cares.

blue

I wouldn't want to have to look at that 3D view with a bad hangover. God bless ya. Now I know why you don't drink.

Holy crap.............It's almost time!

Looks like a typical McMansion set of truss drawings Boss!

I don't see any stepped ceilings and pan ceilings in the hipsets, so that one would be fairly easy to frame, assuming that the truss designer did a good job (most do around here).

You mentioned 200 trusses, that seems to be typical for the cutup roofs of today, but the thing that really scares me is when there are pages and pages and pages of DIFFERENT trusses! I don't mind sorting through 200 trusses...I just hate sorting through fifty or sixty different types of them! I also hate building hipsets that terminate onto girders, which are sandwhiched by girders, etc.

Nice job and thanks for the post and pictures.

blue

Actually, there WERE tray and sloped ceilings in a couple of places. They're just difficult to see. I know it's tough sorting through that many trusses. Especially if the plant doesn't do a good job of marking them. Sometimes on big cut up ones like this, we split the deliveries up. Like send out everything for the left half of the house on one load, then the right half on the second one. That way the guy who loads the truck gets it at least split into 2 sections.

The Constitution only gives people the right to pursue happiness. You have to catch it yourself. [Benjamin Franklin]

I did kinda think there was some steps and slopes in that package...there usually is nowadays.

I like the idea of two trucks and separated. I also agree, proper tagging would greatly speed the process. Around here, it's about 50/50. Some tag well, some think it's a waste of time. In the end, yes...it wastes our time!

blue

Would the truss shops tag properly if there was another $100 in it for them?

"Would the truss shops tag properly if there was another $100 in it for them?"

If you could get it in the right hand, I'm sure it would. If it was a fairly small shop and you knew who would build it.

In a case like ours, this order might be built at any one of 3 shops on either 1st oe 2nd shift. And on an order this big, it would likely be done on 2 different shifts and on several different tables.

Personally I don't feel like you should HAVE to bribe someone to do their job right.

"not that I could pull it off and make money at it. ;)"

That's an interesting problem. I think the framers in this case were doing work for this particular GC on a square foot basis. But most of the houses this GC builds are pretty simple.

So when they got hit with this house, they were pretty ticked off. I don't know what exactly happened, but I think the framers ended up taking a hit.

When someone asks you, "A penny for your thoughts," and you put in your two cents worth, what happens to the other penny?

We've had that happen to us. The amusing thing is that when we refused to do the house for the pittance that the builder wanted to pay, the super told us "you have to take the good with the bad".

I don't think so.

blue

"you have to take the good with the bad".

Nice!

actually got to hear that once ... for a GC I did lotsa custom tile for ...

thot real quick-like ... and just threw it right back at him while defending my now almost double price ... told him .. don't worry ... it'll all level out in the end!

for some reason ... his logic didn't sound so good when it was tossed right back at him! Did I mention that was the last time we ever worked together?

Jeff Buck Construction

Artistry In Carpentry

Pittsburgh Pa

We told the builder that we didn't mind taking the hard house, but we just weren't going to do it for their price. I think I bid it at 49k and they gave 30k on it.

blue

"Personally I don't feel like you should HAVE to bribe someone to do their job right. "

LOL Boss,

You obviously did not grow up in New York!

Nice job in any case.

Jon

Boss Hog,

<!----><!---->

Nice job trussing that house. The designers don’t always make it easy do they?

<!---->

It looks like the framers put them up correctly by how nice the pictures look.

<!---->

I’m sure that a well thought out truss package is a helpful thing, especially if the framers in your area are not familiar with Stick Framing a Roof. That truss package is trickier than most but not as uncommon as some might think. I would think that if that house were to be built in my area it would probably have been conventionally framed since it did not appear to me that large spans were the issue with the roof.

<!---->

When I think or truss roofs I typically find two or three reasons for them.

<!---->

The first being large spans that are easier to accomplish with trusses, especially clear span buildings as seen in commercial applications.

<!---->

The second being economics. Simple repetitive plans can be trussed inexpensively and the price to frame them is less too because the framer is not required to know and perform as much roof math. They cater to the less skilled contractors and the builder can save on labor costs. Simple frames pop up quicker too.

<!---->

The third being a builder’s liability issue. A super for a large semi-custom builder once told me that since they employed such a large number of framers that it was in their best interest to use trusses. The quality control was more uniform and the truss plant assumed structural liability. It seems they didn’t believe that all stick-framed roofs are always created equal. (Btw, I agree)

<!---->

Back to your house. It looks like there was quite a bit of “fillin-in cuts†left for the framer. So much so, that trusses do seem extraordinary for a home of that size and cut-up design.

<!---->

You mentioned that you think the framer “Took a Hit†on framing this house. This indicates to me that you think that when it take 40 hours to design trusses for a home that the installation of the system may take a similar proportionately extraordinary time, (Btw, I agree), and that you doubt that the builder had a fair price for this in his framing labor budget. (wouldn’t be the first time)

<!---->

The “You have too take the good with the bad†comment by blue is something I’ve been told also and “I don’t think so†too. More times than not, when I lost a bid on a home that had justifiable labor cost increases that the builder did not consider, the bid was awarded to an unqualified rival contractor who could not satisfy the contract. These homes would usually end up with any number of problems from over budget too hack job poor. It is not my responsibility to bail people out of their mistakes. If they don’t want to use me to bid and do the job correctly then they will pay for their own education.

<!---->

And another “Btwâ€, I don’t consider bidding a job correctly a “Bribe†to do the job correctly. It is just a Capitalists fundamentalism of extorting a fair price. Lol. If an equally qualified framer can do the job correctly and too acceptable satisfaction cheaper, then I am the “student†and will have to learn to be more competitive in my bidding and find the lowest threshold of competitive “Acceptable Satisfaction†and still make a living while earning the status of being the “Preferred†framer. (That’s a mouth-full that’s easier-said-than-done sometimes)

<!---->

I’m sorry I drifted off topic a little but some of the other responders made some valid comments that, (Btw, I agree) with.

<!---->

I can imagine how much fun you had constructing that truss system. (40 design hours on one roof, whoa! Burnout……) I hope it installed like you intended. If the frame were to plan I would guess it did. Anywho, nice job and thanks for posting it.

<!---->

Mr. Jalp

<!---->

Edit; Sorry Jon, I meant to address this to Boss Hog even though I hope you read it too. Opps!

Edited 8/18/2005 6:40 pm ET by MrJalapeno

How complicated do ya think it'd be to lay out a 3-D for my next tipi?

Be well

a...

The secret of Zen in two words is, "Not always so"!

When we meet, we say, Namaste'..it means..

Where is that house? I did some tile work in a house Identical to that one, all the way down to the drive way and brick keyways in western Illinois!

It was a 280-300k home in an area where building is cheap

"Where is that house?"

I kinda hate to say here, since it isn't my house and I didn't have specific premission to put the info up.

Email me and I'll tell ya privately.

If I remembered your name, I would have asked you where I left my car keys.

Nice work - not that I could pull it off and make money at it. ;)