Hey folks,

I realize I’m going to need an engineer stamp to do this but wanted to see if I could get the specs right before I hand it off.

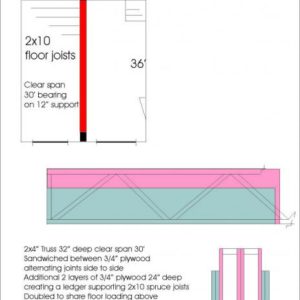

I’m in a position to build a workshop beside my house – 28 x 36 and have everything I need in materials to construct the box beams at no additional cost so I really want to go this route and avoid steel if possible. I also want to avoid using support posts in the span so looking for clear span and want to be able to put walk up storage overhead.

So take a look at my idea and share your thoughts. Open to any suggestions but don’t forget I need to accomplish this using materials already on hand…..I have a load of 2×4’s and 3/4 plywood.

Pedro the Mule – cheap rock solid floors

Replies

Well, yes, you definitely want an engineer. If you are going to use plywood sides to create an enclosed box I don't see the need for the diagonal truss members. You are also better off using one full height blue member than the two 3/4 height you show. Using them horizontally top and bottom might also give more section modulus than using them vetrtically (would have to calculate that to see which is better).

My guess is that you will need to be close to 30" deep for the span you propose. I don't really have anything to base that on, just some seat-of-the-pants extrapolation.

Check the attachment. I think you will be edified.

*Edit- I'm a dummy. I saw the 24" and, for some reason, thought that you were planning on the beam being 24" deep, not 32". I still have nothing concrete to base my guess on, but I would bet that you will be okay. Maybe someone who really knows what they're talking about can contribute.

Jon Blakemore

RappahannockINC.com Fredericksburg, VA

Edited 5/7/2009 8:33 pm ET by JonBlakemore

All I have is past experience and seat of the pants on this one.Largest I saw was an outfit that was using 30" tall box beams with vertical center members 24" oc and half inch ply vertical axis on both sidesThis was to support a garage ridge above in a 28'span, the garage door hangers off ceiling joists, and small amt of space for storage under a 4/12 in a 40# live load roof area.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

If you can find an architect or engineer to design a box beam, you will be surprised how much weight they carry.

An archy did one for me back in 1980. It was 24" deep and spanned about 24 feet if I remember. Wasn't nearly as complicated as the one you propose, but it was carrying roof loads, not floor loads.

John Svenson, builder, remodeler, NE Ohio

I could not get your photo to open, so I really don't know what you have in mind. Is it a beam that someone has designed or what?

It's been some time since I have designed and built a box beam, but as I remember, it is no simple matter. For example, unless you have a sheet of plywood the full length of you beam, it will require designing gussets for the plywood joints that will transfer the stresses from one skin to the other. And that is just for starters. You might Google "The American Plywood Association"

Obviously, I don't know what your experience or expertise is along these lines. I may be way off base and if I am I apologize. Hell, you may know a lot more about it than I do.

I will try again to get you photo to open. Good luck.

I don't get the part on plan about it being supported on 12" posts when you say the goal is to get away from having any posts.

I think you will have a hard time getting an engineer to sign off on this, because it would be so hard for him to ensure the quality of the joints and fastenings, which is the most critical thing on this. Theoretically he could engineer the size easy enough.

My guess would be 40" deep and perfect joinery/layout. Also a way to joint butt ends of ply together.

Welcome to the

Taunton University of Knowledge FHB Campus at Breaktime.

where ...

Excellence is its own reward!

Hi Piffin,

I don't get the part on plan about it being supported on 12" posts when you say the goal is to get away from having any posts.

Sorry for the confusion....the 12" posts will support the ends....actually I'm looking to build the box beam 36' long but the location of the floor to bottom of beam will leave me with 30' clear.......one end will sit directly on a 12" post plus 6" of framing leaving 34 1/2' unsupported....the other end will have a workbench on one side and deep storage on the other so I can bump that beam out from the 6" framed wall another 4' where a second 12" post from floor to bottom of beam will go.....thus 36' beam but actually only 30' clear.

quality of the joints and fastenings

I agree....everything I've googled so far shows 8 d's every 1 1/2" and they recommend it to be backed by glue....."not" to replace any of the nails but simply to "add" to the nail pattern.....I figure I ought to be able to burn out a compressor with that nail pattern hehehh....

I realize it's an awful lot of lumber but I lucked up on what I have.....averaged out to about 3 cents on the dollar....and I've got a bunch of it......yes it's legal....or at least the auction was.....don't know where they got it......probably a bankrupt builder.

The other advantage is I can build it on my time frame and by myself......can't do that with steel.

Pedro the Mule - Stubbornly making more work for myself

The Q open in my mind, not knowing truss design, is whether there is a reason to make your mid members diagonal. The ones I have seen used 'studs' vertical which provided some nailing/gluing surface for the plywood joints to help them transfer stresses from one panel to another.I saved and printed that design guide

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Hi Piffin,

The Q open in my mind, not knowing truss design, is whether there is a reason to make your mid members diagonal. The ones I have seen used 'studs' vertical which provided some nailing/gluing surface for the plywood joints to help them transfer stresses from one panel to another.

Once again I agree completely....I had started my design based on photos of web floor joists but I can see the reason for blocking. Basically the plywood eliminates the need for the inner web but the blocking ties the plywood together.

If I can get the span to work....I figure I can build the skeleton form on the ground first then use a small block and tackle to raise each end in place.....then throw in some dead-men and create artificial camber.....how much? I guess that's up to an engineer. I can then glue and nail the plywood into place a sheet at the time. Once setup, remove the dead-men and I'm good to go.

Pedro the Mule - With that camber it should sway like my back

>but the blocking ties the plywood together.<

I'm thinking more to prevent buckling, but I dunno for sure. Once the plywood moves out of the vertical plane its strength drops off fast.

"But lumber blocking ties the plywood together" as mentioned in another post.

Lumber blocking not necessarily or likely to be adequate to transfer the stresses.

A span this long is not something to take lightly. Depending on the loading, you could be dealing with some major stresses here. I don't want to be an alarmist, but this is not something you want to take lightly. Someone could get hurt.

I did some that spanned 36 ft. that, IIRC, had 4 2x6 top cords, 4 2x4 bottom cords with three 3/4 plywood webbs/flanges. One on each side and another in the middle. It was hell for stout, but we were caring some pretty good loads.

As Piffin had indicated, how all of the pieces are assemble is very critical. They all have to work like one. The glue has to be like a weld. Stronger than the material itself. Plain ole construction adhesive or yellow glue is not going to cut it. The quality of materials used have to be better that common materials found of the average job site.

Other than being highly labor intensive, the reason one does not see more of this type of construction used in every day work out on the building site, is the need for over site and control of the construction/assembly process.

Edited 5/8/2009 6:35 pm ET by oops

If you're designing for a load of 40 psf, for example (30 psf live, 10 dead), with a 28' wide room split in the middle you're looking at a beam load of 560 pounds per linear foot (plf). Over a 36' span, that's a helluva load. You're looking at a peak bending moment of over 90,000 ft-lbs. Just by consulting the tables in APA pub "Design And Fabrication Of Glued Plywood-Lumber Beams", if you're shooting for a beam depth of 36", you can't make it work using the sample table in there. And going to another beam construction would involve some serious calculating. You're looking at a truly massive beam to span that distance. While the table in that publication assumes 15/32" ply, and you said you've got 3/4", the thickness of the plywood is only a small component of the beam's strength.Just a rough guess, you could make it work with a box beam constructed from 6 2x4s for the top flange, 6 2x4s for the bottom flange, and four webs of 36" deep 3/4" ply (one web on the outside, two in the middle of the 2x4s, and one on the other side). That's a truly massive structure, just think about the lumber involved. And it's just a rough guess, I'm not double-checking any of my math or trying alternate solutions. Clear span is nice, but you'll probably have a beam three feet deep running down the center of your ceiling - I'd much rather have a post or two, and a significantly smaller beam.If you put in just one post, your peak moment drops from about 90,000 ft-lb to about 22,000 ft-lb (a factor of four, or two squared - halve the span, and you get a quarter of the bending moment with this type of uniform loading). You could use a 20" deep beam with just three 2x4s for the top and bottom flanges instead. And you'd still have a huge room with just a single post dead center, something to think about.Again, all of these numbers are rough and unconfirmed, please don't go and use them to try and build something without getting it spec'd and approved. It's just to give you an idea of the project you're contemplating.

Hi oops,

I did some that spanned 36 ft. that, IIRC, had 4 2x6 top cords, 4 2x4 bottom cords with three 3/4 plywood webbs/flanges. One on each side and another in the middle. It was hell for stout, but we were caring some pretty good loads.

Do you recall how deep they were?

Other than being highly labor intensive, the reason one does not see more of this type of construction used in every day work out on the building site, is the need for over site and control of the construction/assembly process.

I'm just the one to get it done correctly....I lapped my OSB wall sheating over the floor joists exterior band linking each story together and glued it as well.....all this before it became a buzz word to tie floors together. Details are my game. The biggest thing I'm looking for from the guys with experience....is "can it be done" with the dimensions given that fit the structure I want to build.....if the answer is yes, then I'm willing to plunk down the dough with an engineer. If not, then that's money saved.

Thanks mucho - Pedro the Mule

IIRC somewhere between 24" and 30", but I'm not sure. I do remember that the span to depth ratio was pretty low. That is the reason that they were pretty beefy. Your beam (span to depth ratio) that you mentioned should do what you want with no problem.

To do things right or go the extra mile to do them better is a judgement call. Unfortunately, sometime the market just won't let you do it. It can price you out of the ball game.

I'm with you on the details. To me it's fun to figure out ways to do neat things. I've got no problem with your using a box beam. Done right, it could be a fun thing and good experience. I have just been trying to make the point of being sure that you were aware that this is above normal carpentry.

If you like and are pretty good (you don't have to be a genus) with math, like the technical side of things and are willing to dig out the information, you could do it.

There are two aspects to what you want to do. One is the design of the beam. Two is the understanding of the importance of the assembly. If you can't do the design, then get an engineer. You can probably get a feel or understanding of the construction by reading some of the stuff your could get from APA.

Have fun, but just be careful.

Hi oops,

I'm with you on the details. To me it's fun to figure out ways to do neat things. I've got no problem with your using a box beam. Done right, it could be a fun thing and good experience. I have just been trying to make the point of being sure that you were aware that this is above normal carpentry.

The main reason I built the entire house, piece by piece.....every last bit of it.....was because I couldn't hire the quality of labor I wanted.....built it during the big housing boom a few years back.....the few truly qualified people were already fully employed overtime with the local custom builders. As an engineer I have that mentality for perfection beyond possibility so the details of a box beam will be a piece of cake. My only real downside to this is my engineering degree is in electronics.....not structure so my thinking is sometimes skewed and I need the critiquing I find around this forum.<!----><!----><!---->

reading some of the stuff your could get from <!----><!---->APA<!---->.<!----><!---->

Will do.....I get my cheap thrills from studying 10 hours to save $10.....that's the hobby side......it sure beats my FIL's $186 per pound Spanish mackerel filets.....by the time you buy the licenses, pay the taxes, buy the boat, pay the gas, the maintenance......etc......not to mention the $125,000 little boat slip out in the boat parking lot collecting barnacles 24/7......hmmmm a little wood to build a dock, surround it with free tide fed water and sell it for megabucks.....sounds fair to me....<!----><!---->

Pedro the Mule - Cheapest Old Gray Mule around

Unless this is for hobby/ego purposes... steel beam prices are down around $800/ton, use the cheap lumber for something else.

The awful thing is that beauty is mysterious as well as terrible. God and the devil are fighting there, and the battlefield is the heart of man.- Fyodor Dostoyevski

Guessing around $1200 plus crane to set it.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

A bargain at twice the price!Given that the finished box needs to be designed and then approved by engineer, plus, I know y'all are better carps than I, but the set up to build the beam straight is probably as much as the beam itself.I think it was Hemingway that said if you have a great line in your head, throw it away... as you'll write terribly finding a way to fit it in. I feel the same way about free, leftover, and deep discount materials.

The awful thing is that beauty is mysterious as well as terrible. God and the devil are fighting there, and the battlefield is the heart of man.- Fyodor Dostoyevski

Hi FNbenthayer,

I know y'all are better carps than I, but the set up to build the beam straight is probably as much as the beam itself.........I feel the same way about free, leftover, and deep discount materials.

Yeah but don't you think the first man to move Mount Everest to a new country in one piece will get the biggest ego trip of a lifetime.

I have a great passion for making something out of nothing, for accomplishing what they say can't be done......and besides.....although steel might be the way to go.....I can't do that by myself....at the very least I'd need to hire in a crane & operator plus bring in a few people to help me set the thing. I want to do this box beam thing myself for the satisfaction in spare time under tarps for the WOW! factor.

I truly am open to other ideas but it still has to fit what I'm physically capable of doing as one stubborn mule headed person. I work a very mentally challenging life and get my stress relief from physical labor but I also choose to work smart as well as hard. Doing something of this nature is my golf, fishing, boating etc.

So it's less of "what is the best way" and more "what is the best way given materials on hand, my labor and my self competitiveness.

but the set up to build the beam straight is probably as much as the beam itself.

Actually a couple of braced dead-men set to the proper camber, a couple of taught strings and half a dozen floor joists carefully measured as everything comes together will be all it takes for accuracy......piece of cake......

Pedro the Mule - Ain't racked up enough splinters yet

Edited 5/10/2009 6:44 pm ET by PedroTheMule

It's your vacation... work safe and keep us updated.

The awful thing is that beauty is mysterious as well as terrible. God and the devil are fighting there, and the battlefield is the heart of man.- Fyodor Dostoyevski

Hi FNbenthayer,

It's your vacation... work safe and keep us updated.

I appreciate the morning chuckle. It'll still be a little while before I actually break out the tools for the beam....I'm still clearing tree's and getting them sawn for the rafters. I have the posts cut, dried and treated and expect to plant those by the end of summer, then I can begin the box beam. I'm going to secure a huge tarp to the post and beam framing once I have it skeletoned out. That'll make it easier and safer to work in. We seem to have extended rain everytime I start an outdoor project. Should have done this two summers ago during the drought......would have ended it!

Thanks for the well wishes, I'll certainly enjoy and will take every precaution I can.

Pedro the Mule - Now if I could only find that engineers pencil

Ain't that the truth. But daing, I hate to throw it away. I guess it's my upbringing.

My wife's dad made his fortune, after WWII, wrecking and salvaging closed military bases etc. Materials were scarce and labor was cheap.

x marks the spot! got any better pics??

View Image

"...craftsmanship is first & foremost an expression of the human spirit." - P. Korn

bakersfieldremodel.com

Hi Huck,

x marks the spot! got any better pics??

Sorry, the included sketches are nothing more than the initial design straight out of my head. With something of this nature, I know for a fact that the county inspection department will want it engineer stamped so I would expect for said details to be included but I wanted to run it past you fellas in general because my current rough design solves a lot of issues I'll be dealing with such as I'll be the only labor and I can easily build this in place by myself. It also carries the floor joists along the built up ledger, etc.

Pedro the Mule - Now that it's out of my head, how do I get it back in?

Have you looked at the APA publications on box beams? They are very exhaustive covering all aspects of the design and loads. You might need someone to sign off on your beam, but I'd bet you could design the whole thing from the APA stuff.

Hi fingersandtoes,

Have you looked at the APA publications on box beams? They are very exhaustive covering all aspects of the design and loads. You might need someone to sign off on your beam, but I'd bet you could design the whole thing from the APA stuff.

Thank you, I downloaded something yesterday.....about 60 pages or so....I think I'll take it to lunch with me tomorrow....should make for interesting conversation on mothers day!

The quick info I've come across so far only goes up to 24' but I think the info I got yesterday provides the math to figure greater lengths.

Pedro the Mule - My ol' stubborn head is gonna hurt after this

Do you have a link or a report number on that publication? I can't find anything that large at the APA site.

Jon Blakemore RappahannockINC.com Fredericksburg, VA

Hi JonBlakemore,

Do you have a link or a report number on that publication? I can't find anything that large at the APA site.

I grabbed a couple of the files I've been working with this week and don't remember which has which at this point but everything I have covers areas of load, spans etc. I'll post anything else I find as I come across it again.

http://www.awc.org/helpoutreach/ecourses/STD303/wfcm2001workbookandappendix.pdf

http://www.awc.org/pdf/2001WindSeismicSupp.pdf

http://ilevel.com/literature/TJ-9001.pdf

http://www.awc.org/pdf/TR05.pdf

http://www.awc.org/pdf/LRFD_Glulam.pdf

http://www.pryda.co.nz/uploads/Floor%20Truss%20Guide%20to%20Spec%20Oct06.pdf

http://www.awc.org/pdf/NDSCommentary2005.pdf

http://www.awc.org/publications/papers/WDF14-4-2005DesignValues.pdf

http://www.awc.org/software/protectedPDF/AWC-WCD6-Permanence-0406-protected.pdf

http://www.gp.com/BUILD/DocumentViewer.aspx?repository=BP&elementid=3216

http://www.awc.org/pdf/DA6-BeamFormulas.pdf

Check out this site too.... http://www.awc.org/search/search.asp?zoom_query=groove

This is some area of research that got me started....I'm planning to build a pole barn http://newstore.southernpine.com/images/ref203.pdf

http://www.awc.org/pdf/wcd4.pdf

Have lots of fun.....I have!

Pedro the Mule - Not about to be out done by a pdf