I purchased a 1958 brick ranch in Denver this summer. One of the perks was a new water heater and boiler. One of the drawbacks was the manor in which the HVAC company installed the duct supplying outside air to the furnace area. They installed 2, one for each gas burning appliance. Is this normal? What options do I have to clean it up?

Discussion Forum

Discussion Forum

Up Next

Video Shorts

Featured Story

Making your own heated floor assembly may save money, but it can also cause problems.

Highlights

"I have learned so much thanks to the searchable articles on the FHB website. I can confidently say that I expect to be a life-long subscriber." - M.K.

Fine Homebuilding Magazine

- Home Group

- Antique Trader

- Arts & Crafts Homes

- Bank Note Reporter

- Cabin Life

- Cuisine at Home

- Fine Gardening

- Fine Woodworking

- Green Building Advisor

- Garden Gate

- Horticulture

- Keep Craft Alive

- Log Home Living

- Military Trader/Vehicles

- Numismatic News

- Numismaster

- Old Cars Weekly

- Old House Journal

- Period Homes

- Popular Woodworking

- Script

- ShopNotes

- Sports Collectors Digest

- Threads

- Timber Home Living

- Traditional Building

- Woodsmith

- World Coin News

- Writer's Digest

Replies

That does not appear to be one for each appliance, but rather an outlet high and one low. Which is what is required.

However, when I had one it was one duct with an opening high and low.

But from the look of the space I wonder if you require external combustion air or not.

William the Geezer, the sequel to Billy the Kid - Shoe

Bill, et al: Why the requirement for one high & one low? Usually, I can see the rationale. This one escapes me.DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

I really don't know.My guess is that any fumes accumulate that they can escape..

William the Geezer, the sequel to Billy the Kid - Shoe

I forget, but it's been a code requirement for a LONG time. I think it may be to ensure that the mechanical room is 'vented' of air high and low. Maybe it was ... in case the owner switched from propane to gas or some such.

ALL: Makes me feel better that the resident factotum, Bill Hartmann, didn't know the reason! I could not figure why two INLETS for combustion make up air. I'd a'thunk that one inlet at floor level would be it - combustion fumes go up the chimney.Thannks.DonDon Reinhard

The Glass Masterworks

"If it scratches, I etch it!"

I'm no expert like Bill, Clewless or Dan, but my WAG is that the hot combusted air takes up more space than the cold incoming air, thus (as my building inspector says) 2 incoming ducts for every outgoing one to compensate for the difference.

And second, different gases (CO, CO2, Propane, nat gas) have different weights compared to ambient air and can settle (and have various effects) at different layers and concentrations within an enclosed room. The two different heights eliminate the possible ill effects.

The same BI also suggested to place a 5 gallon plastic drywall compound bucket around the lower one to minimize the movement of heated air back up thru the lower vent - thus acting like a P trap in sink installations.

> I'm no expert like Bill, Clewless or Dan, but my WAG is that the hot combusted air takes up more space than the cold incoming air, thus (as my building inspector says) 2 incoming ducts for every outgoing one to compensate for the difference.By that reasoning you should only need half a duct.

As I stood before the gates I realized that I never want to be as certain about anything as were the people who built this place. --Rabbi Sheila Peltz, on her visit to Auschwitz

As I qualified, I'm no expert...

I now see what you mean.

But why did the BI tell me two for one?

Because he was grasping for anything "logical" to explain the rule.

As I stood before the gates I realized that I never want to be as certain about anything as were the people who built this place. --Rabbi Sheila Peltz, on her visit to Auschwitz

High/low vents are a throwback to boiler rooms. The low one is combustion air and the high one is relief air.

The purpose of the relief air vent is to remove hot air from the boiler room.

The temperature could get high enough to compromise the temp ratings of any electrical equipment.

Up here, I don't need relief air in a furnace room, but I still need it in commercial boiler rooms.

>>Bill, et al: Why the requirement for one high & one low? Usually, I can see the rationale. This one escapes me.As we've seen, lot's of different theories - I've taken combustion analysis courses and the experts don't know, either. The Code Worketh In Mysterious Ways!One problem with this sort of setup is cold air poring in through the lower supply duct.To reduce/stop that, you can put an upside-down goose neck at the bottom or have it terminate inside a topless box on the floor.

"Man's capacity for justice makes democracy possible, but man's inclination to injustice makes democracy necessary." Reinhold Neihburh: 'The Children of Light and the Children of Darkness'http://rjw-progressive.blogspot.com/

"To reduce/stop that, you can put an upside-down goose neck at the bottom or have it terminate inside a topless box on the floor."Or do what I did. Replace the furnace(s) and WH with sealed combustion units..

William the Geezer, the sequel to Billy the Kid - Shoe

one terminates at the ceiling... the other at the floor...

correct???

and you don't have high efficiency appliances either....

correct???

that's the way it's suppose to be...

the aesthetic improvements are up to you...

Life is not a journey to the grave with the intention of arriving safely in a pretty and well preserved body, but rather to skid in broadside, thoroughly used up, totally worn out, and loudly proclaiming

WOW!!! What a Ride!

Forget the primal scream, just ROAR!!!

That's actually a fairly neat installation, though I'd question how long the outside ductwork will last before it's destroyed by lawnmowers, weedwhackers, kids with more time than sense, etc.

brick around them?

paint them?

They had to chunk through the brick for the outside intakes when a window was very close. If the aesthetics are up to me, any ideas? We want to finish that room and the duct work takes up a lot of space. The outside intakes well I guess beauty is in the eye of the beholder.

I still wonder if you need those at all. If not you can remove the ducts and brick over the holes.But a lot depends on the details of the house construction. And finishing off the area might make enough difference.This will give you a start.http://www.google.com/search?hl=en&rlz=1B3GGGL_enUS334US334&q=combustion+air+requirements&revid=2038208453&ei=Kn_HSqa4Jo6V8AaD25HiCA&sa=X&oi=revisions_inline&resnum=0&ct=broad-revision&cd=5And you might want to get an HVAC person that can run draft tests.And you might want to get a blower test done on the house. Specially if you have a utility company or state/local program that will help pay for it.That can identify how much leakage that you have and what the cost of tightening up the house would be. Which all affects the need for outside combustion air.Now I have no idea of how old the house is or how tight it was construced in the first place..

William the Geezer, the sequel to Billy the Kid - Shoe

I had a contractor come over who has done work for me before. He said that there was not a limit to the length of the combustion air ducts, hence we could run them between the floor joist and out the other side of the house. Also that you could use two 6" ducts as they did or one 8" duct simplifying install.

Bill you mentioned one duct with a high and low opening, that may be the way to go.

Would it be a good idea to put a flap on a combution air inlet?

A light flap that would open up when air was demanded? "There are three kinds of men: The one that learns by reading, the few who learn by observation and the rest of them have to pee on the electric fence for themselves."Will Rogers

"

Would it be a good idea to put a flap on a combution air inlet?

A light flap that would open up when air was demanded? "

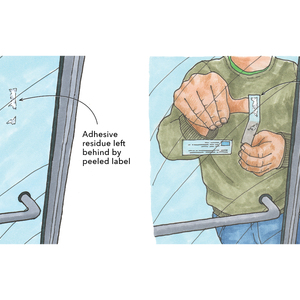

Your question reminds me of a product described in Andy Engle's article on the no mold basement (FHB, pg 82 Feb/mar 2005). A fabric damper that acts like a check valve preventing hot basement air from going out a pair of make up air ducts. The damper is manufactured by Tamarack.

I've attached a pdf spec sheet from the manufacturer (hopefully can attach here).

I've been planning on finishing my basement for a while now and this combustion air makeup source has been an item of concern to me since I'm not keen on allowing freezing air (massachusetts) into my basement in the winter.

Has anyone used one of these fabric dampers as described? If so are you happy with it? did you get a permit and did the BI accept use of the damper?

I called Tamarack and asked if it met code in massachusetts (tamarack is coincidentally in MA, same as me). They said they didn't know.

"Has anyone used one of these fabric dampers as described? If so are you happy with it? did you get a permit and did the BI accept use of the damper?"

You are being summoned.

Jon Blakemore RappahannockINC.com Fredericksburg, VA

Hi Jon

We use the six inch version all the time as make up air control behind dryers in tight homes. I've always called them a cape back draft damper to differentiate from the regular tin butterfly dampers we use on range hoods. Re: this discussion I can see putting a back draft damper on the upper vent but I like leaving the lower vent open to allow petroleum fumes to escape by gravity if present. Regardless, I really like the idea of isolating the furnace room from the rest of the house for indoor air quality as well as for thermal issues. We've been doing this even with sealed combustion equipment that doesn't require a vent. two layers of 1.5" foil faced polyisocyanurate with offset joints. (we really do it to control waste heat from the big solar tanks we use, even insulated tanks dump a lot of heat in the summer around here.)y'all be wellMichael------------------

"You cannot work hard enough to make up for a sloppy estimate."

Second what Shelternerd said.

My house has a utility room in the basement with all the apliances in it.

I think it is a good idea to isolate them from the rest of the house or basement.

If there was a fair amount of cold air being pulled in it is just in the one utility room.

And utility rooms tend to be warm anyway.

One thing that is missing in our is a floor drain. Just in case. "There are three kinds of men: The one that learns by reading, the few who learn by observation and the rest of them have to pee on the electric fence for themselves."Will Rogers

No doubt about the floor drain. Our last pump room we did the floor like a shower with an EPDM full room drain pan with a 2" PVC shower drain, no trap to daylight just above the gutter drain. Lotta solar tanks in there but only one combustion appliance, a nat gas quietside demand water heater. We took the condensation into a washer box that wyed into the showed drain under the floor.------------------

"You cannot work hard enough to make up for a sloppy estimate."

"Regardless, I really like the idea of isolating the furnace room from the rest of the house for indoor air quality as well as for thermal issues."

Is this practical in a cold climate that gets well below freezing in the winter? Should one be at all concerned about cold water pipes freezing if they're in an isolated room with ducts to the outside?

One presumes you keep the rest of the house heated.

As I stood before the gates I realized that I never want to be as certain about anything as were the people who built this place. --Rabbi Sheila Peltz, on her visit to Auschwitz

"

125092.53 in reply to 125092.52

One presumes you keep the rest of the house heated."

Yes of course. I guess I should have elaborated, I assume one has at a minimum a cold water pipe feeding a water heater in a typical furnace room.

Well, presumably the furnace room is inside the heated envelope. Even a well-insulated high-efficiency furnace (which we're not talking about here) throws off enough heat to keep the furnace room at or above "room" temperature. The amount of makeup air coming in isn't enough to negate that effect.

As I stood before the gates I realized that I never want to be as certain about anything as were the people who built this place. --Rabbi Sheila Peltz, on her visit to Auschwitz

It looks like it would work. I was thinking a flap that would close with gravity.

I've seen (somewhere) a flap that had a pivot arm come out the side with an adjustable counter balance on it.

If you found hat it was opening when there was no demand you could increase the weight a bit.

One issue I see is that if you took the duct out on a side of the house that had wind coming at it there would be considerable pressure there and it would blow open any flap or fabric.

Maybe there is a direction of prevailing cold winds in your area. Put the duct opening on the leeward side. "There are three kinds of men: The one that learns by reading, the few who learn by observation and the rest of them have to pee on the electric fence for themselves."Will Rogers

The rationale for the two ducts, one high and one low, can be understood if you think about the term that the code uses to describe the requirement:

The code calls it COMBUSTION AND VENTILATION AIR, not just "combustion air".

The upper one is to ventilate the appliance enclosure not only from heat buildup, but also in case the primary vent would fail.

The lower one is to supply combustion air to the burners.

HOWEVER, more recent editions of the code have recognized the fact that both ducts tend to bring air into the space, and that, in cold climates, this is not good. Therefore, the code now allows you to have ONE opening sized at 1 sq. in./3000 BTU's, and requires that the opening be within 12" of the ceiling.

So, if you had a furnace and water heater with a combined BTU input of 120k, you could supply all the combustion/ventilation air with a duct having a cross-sectional area of 40 sq. in.

Also, the code allows you to give some credit to air infiltration of the building itself, but it can be a cumbersome process to convince your BI just what portion of the needed air is available thru infiltration.

Pay no heed to the misguided suggestion that you can reduce the inflow of cold air by using an upturned end on the supply duct or any variation of the idea. Proponents mistakenly compare it to the p-trap on a plumbing fixture, which would work if the dip of the duct were filled with water, but, of course, it's not. Air will flow from an area of higher pressure to lower regardless of any ups or downs in the duct.

From personal experience, p-traps on combustion air work. Up here they are code.

Just saying.

Please explain.

HOW do they work?

>>Pay no heed to the misguided suggestion that you can reduce the inflow of cold air by using an upturned end on the supply duct or any variation of the idea. Proponents mistakenly compare it to the p-trap on a plumbing fixture, which would work if the dip of the duct were filled with water, but, of course, it's not. Air will flow from an area of higher pressure to lower regardless of any ups or downs in the duct.I've done it. It works.'Yes, there can be pressure issues, but the negative pressure typically found in a basement is relatively slight, outside location and pressure zones caused by air movement around the house are more important."Man's capacity for justice makes democracy possible, but man's inclination to injustice makes democracy necessary."

Reinhold Neihburh: 'The Children of Light and the Children of Darkness'

http://rjw-progressive.blogspot.com/

Edited 10/14/2009 1:06 pm ET by rjw

I know I'm taking on a wide-spread and beloved misconception here, but the so-called air trap will not work. Physics won't allow it, or, as Scotty used to tell Cap'n Kirk: "Ya canna defy the laws of physics."

The usual (mistaken) explanation goes like this:

You make a p-trap in the combustion air duct, which is usually in the basement. The cold air from outside will pool in the dip of the trap, similar to water in the dip of a plumbing p-trap, and this pool of cooler, denser air will effectively block, or at least slow, the inflow of cold air from the outside.

Wrong. Here's why:

The source of the cool air is the higher column of cool air in the tall part of the duct that runs from the even colder air outside. As long as the inside end of the duct is lower than the outside end, the weight of the outside, colder air will cause flow. Since it's heavier, it will push the pooled air in the dip up and out into the room.

"But,wait", you say. "What if I make the inside end as high or higher than the outside end? Won't that cancel the effect of the heavier air?"

Yes, but that brings us to the next and more likely force that moves air in houses: pressure differences. If the space where the duct ends is negative compared to the outside air, the positive pressure of the outside air will push air into the space regardless of ups or downs of the duct. Air always moves from an area of greater pressure to one with lower pressure.

Basements are normally negative compared to the outside air pressure due to the stack effect of the house. The house is like a hot air balloon that's too heavy to lift--the warmer air is always rising and seeping out at upper levels and being replaced at lower levels. This is true unless some mechanical means of pressurizing the basement is at work. In that case, the positive pressure in the basement will push warm air out through the combustion air duct, and the net effect on your heating bill is the same.

To make things worse, basements are also de-pressurized in most cases by the operation of the furnace blower. Duct systems are notoriously unbalanced such that they de-pressurize the basement while pressurizing the upper floor. Prove this to yourself by feeling the air rushing into the basement under the closed basement door while the furnace blower is running. Such de-pressurization in far greater than any caused by stack effect or air density differences caused by temperature differences.

>>I know I'm taking on a wide-spread and beloved misconception here, but the so-called air trap will not work. Physics won't allow it, or, as Scotty used to tell Cap'n Kirk: "Ya canna defy the laws of physics."Sometimes, reality outweighs theoretical physics.I've been in the field with pressure gauges, draft gauges and the like measuring stuff that actually happens.I know all the theories you recited.And I know what happens in the field.Some of the generally accepted rules don't actually happen, and certainly not all of the time.Were you aware, for example, that the draft tables are computer generated and that they actually begin with the admonition that the system designer is responsible for whether installations "by the book" actually work.Usually they do, but I've tested a number that are "by the book" and don't work as intended.And yes, I have taken advanced courses in combustion analysis and carbon monoxide testing.

"Man's capacity for justice makes democracy possible, but man's inclination to injustice makes democracy necessary." Reinhold Neihburh: 'The Children of Light and the Children of Darkness'http://rjw-progressive.blogspot.com/

Let me say first that I apologize if my comments have offended you or others who believe in the air trap. If it really works, someone will be able to explain how.

I'm not talking theories only. I regularly check pressures and performance of residential HVAC systems by the hundreds every year for the past 17 years in my job as a mechanical inspector. I use manometers, flow hoods, flow plates, smoke, etc on questionable installations to nail down what the problem really is.

Without going over all the ground I've already covered, I repeat my question:

HOW would the so-called air trap work? Explain it. If if works, explain it. What principle of physics makes it work? What conditions in the house would create the means to make it work? If you can't explain it, maybe someone else in this forum can. Or not.

I understand your point about the draft tables, and agree completely. But that doesn't mean they're wrong--it's just that the draft tables were formulated under controlled conditions, conditions which may not exist in any given installation. In fact, I believe your point only strengthens what I'm saying: the pressures induced by the buoyancy of temperature differences are small compared to the pressure differences induced by mechanical means.

Based on that, do you recommend a combustion air vent at all?We're in a 1929 home with HW heat and a gas furnace and water heater in our basement. Half the basement is finished, the other half (including the mechanicals) is not. It's been suggested to me before do do the vent/bucket thing but it just didn't make sense to me to cut a hole in my basement to allow February MN air into the basement. We do have carbon monoxide detectors installed and they have never read above zero. Should we still consider some sort of vent? Short of replacing the units with enclosed combustion systems, is there a method that would work better than the bucket/p-trap methods?

In a 1929 home that has not been subject to significant renovation, it's unlikely that you need a combustion air vent for safety reasons. Having one might actually reduce your heating costs and/or improve comfort, though.

As I stood before the gates I realized that I never want to be as certain about anything as were the people who built this place. --Rabbi Sheila Peltz, on her visit to Auschwitz

"Having one might actually reduce your heating costs and/or improve comfort, though."

Can you explain and or give support to this? Intuitively, it would seem that letting in outside air would be a bad thing.

The outside air is coming in SOMEWHERE. If it's coming in through, say, the living room, the tendency is to turn up the heat to compensate. Bringing in the air in the immediate vicinity of the furnace (where things are probably too warm anyway) results in less air coming in other places and more comfort.

As I stood before the gates I realized that I never want to be as certain about anything as were the people who built this place. --Rabbi Sheila Peltz, on her visit to Auschwitz

But the air that is coming in is only doing so when the furnace is running. Wouldn't the air in the vent come in constantly?

If things were perfectly sealed, no. For air to come in it has to also go out somewhere else.

As I stood before the gates I realized that I never want to be as certain about anything as were the people who built this place. --Rabbi Sheila Peltz, on her visit to Auschwitz

Okay, but...

If you have what the OP has with a high and low vent, aren't you setting up a natural convective loop?

Yeah, I don't see the point of the high/low vent setup, in a standard residential setting. I think sometimes code is based on the same faulty reasoning as the bucket idea.

As I stood before the gates I realized that I never want to be as certain about anything as were the people who built this place. --Rabbi Sheila Peltz, on her visit to Auschwitz

That's where I don't understand the concept. I don't see how cutting a whole in my wall would IMPROVE heating in the winter. ;o)The 'it has to come from somewhere' argument does make sense. I'd rather have it not come in the front door. That said, our mechanical room is in the basement next to our family room. Since p-traps don't work, is there a DIY-esque solution to create a vent that doesn't constantly leak the cold air into the floor of the basement?

The air won't come in through point A unless it's going out through point B (or C or D). In a WELL-SEALED house there would be no flow (to speak of) through the vent when the furnace isn't drawing combustion air.In a not-so-well-sealed house, it's a bit of a cr@p-shoot. You could in theory (and ignoring code) install an electric damper on the vent to only open it when the furnace (or water heater) is firing.Another approach is to attempt to set up the vent so that (again, ignoring code) there's not enough temperature gradient to make the air flow downward when there's no "draw" from the furnace. Our vent (before we installed a HE furnace and removed it) was installed from the unconditioned, vented attic to the utility room in the basement. (This is no longer "code", I understand.) The air in the attic would tend to be 10-20 degrees warmer than outside air (due both to heat leakage from below and to warming by the sun), so there was a significantly smaller temperature gradient driving air downward. Most of the time there was no noticeable draft through it except when the furnace was firing.I don't know what you can do that's "to code".

As I stood before the gates I realized that I never want to be as certain about anything as were the people who built this place. --Rabbi Sheila Peltz, on her visit to Auschwitz

Just a question. Why not insulate & weather seal the mechanical room to minimize heat transfer between the furnace & the rest of the basement? Then the "open hole" to the outside would produce minimal cooling to the rest of the house even if some sort of circulation did occur?Saw a friend's house the other day that had done that. He has an oil-fired boiler right in the middle of his finished basement that has a wide, completely open stairway to the rest of his house. He built the house back in the early 70's. Hasn't had a bit of a problem with air infiltration to the rest of his house.After I saw it, the only thing in my mind was "WTF didn't I think of that"?

You could do that. Of course, the more you enclose the furnace, the more you bump up against other code issues regarding ventilation.

As I stood before the gates I realized that I never want to be as certain about anything as were the people who built this place. --Rabbi Sheila Peltz, on her visit to Auschwitz

>the more you enclose the furnace, the more you bump up against other code issues regarding ventilation.Dan, I don't want to hijack the thread, but would you mind elaborating on that a little bit? I'd like to know what those issues are.

I'm certainly no expert, but as I understand it the code gets more stringent (WRT ventilation) the smaller the enclosed space around the furnace. I've no idea what the magic numbers are in terms of cubic feet, etc.

As I stood before the gates I realized that I never want to be as certain about anything as were the people who built this place. --Rabbi Sheila Peltz, on her visit to Auschwitz

This reply is greatly delayed (been elk hunting), and others in the forum have explored various methods of bringing in combustion/ventilation air that are effective in various situations.

In your 1929 house, I very seriously doubt that you need another source of combustion air. Factors that will determine this:

You say the half of the basement that contains the equipment is unfinished. Even if this space amounts to less than the code-required 50 cu. ft./1000 BTU's, all you would need to do is provide a way for air in the rest of the house to communicate with the equipment enclosure. This can be done with 2 grilles in the wall separating the two areas, each with openings of 100 sq. in., and having one high and one low.

Also, it's likely that there's a masonry chimney that rises up out of the enclosure and into the ventilated attic--look closely at this chimney and you may find that there's something like a one-inch air space all around it that continues all the way to the attic. This would be a huge source of combustion/ventilation air.

Probably the enclosure in not really "enclosed" in the sense of air-tightness. Likely the ceiling area is open at the floor joists such that air moves freely in and out of the enclosure to other spaces. In other words, you live in a very leaky house unless extraordinary measures have been taken since it was built to seal everything. This leakage gives you good indoor air quality at the expense of high heat bills. But you probably don't need another hole in the envelope.

It's not unusual for inspectors (like me) to get fixated on combustion air because it's an easy thing to focus on to make us feel we're doing a public service to ensure safety. But when you look a little deeper into the dynamics of air movement within buildings, you find that other factors are far more relevant both to safety and to efficiency. I won't fill this reply with examples, I only mention this to warn you that if you are trying to please an inspector, you could get one who takes a very narrow view of combustion air, and who may not be willing to look at all the possible sources of C/A that your home already has.

RDesigns,

Thanks for your logical, succinct, and correct debunking of the "P-trap in the combustion air duct" nonsense. Well done.

Martin Holladay, senior editor

http://www.greenbuildingadvisor.com

>>Let me say first that I apologize if my comments have offended you or others who believe in the air trap. If it really works, someone will be able to explain how.

Well, I test too, and I have found that it works (at least at times.)

I'll leave the theory to others.

"Man's capacity for justice makes democracy possible, but man's inclination to injustice makes democracy necessary." Reinhold Neihburh: 'The Children of Light and the Children of Darkness'http://rjw-progressive.blogspot.com/

Until we installed a HE furnace, we had such a combustion air feed into our utility room, and I was never able to detect much of a flow from it. I suspect it's possible to put a bucket under the thing, wave you hand around, say "See, there's no air flowing now," and claim that the bucket works. (In fact, I KNOW it's possible to do that.)

As I stood before the gates I realized that I never want to be as certain about anything as were the people who built this place. --Rabbi Sheila Peltz, on her visit to Auschwitz

>>Until we installed a HE furnace, we had such a combustion air feed into our utility room, and I was never able to detect much of a flow from it. I suspect it's possible to put a bucket under the thing, wave you hand around, say "See, there's no air flowing now," and claim that the bucket works. (In fact, I KNOW it's possible to do that.)

Each situation can be different - general rules drawn from one installation don't really establish much

"Man's capacity for justice makes democracy possible, but man's inclination to injustice makes democracy necessary." Reinhold Neihburh: 'The Children of Light and the Children of Darkness'http://rjw-progressive.blogspot.com/