Hello everyone…

Please let me preface all of my following statements and questions with a little background on my situation. This is the first forum to which I have ever posted. (I know, pretty strange these days). Most of the time I try to glean what I can from other people’s threads who have similar questions. This method has served well in the past, but it is not quite cutting it this time. I don’t feel that I have a situation completely unique to ONLY me, but I cannot seem to find one similar enough to jump on board with the answers.

OK… here we go

My questions involve an almost complete tear-down of a 1.5 story, brick and stucco home built outside of Denver, Colorado in 1947. Now that I have been working on it for a year already, I get the feeling I should have bulldozed the thing and started from scratch, but I’m in it up to my eyelids now.

Starting from the ground and moving upwards, I have repaired small cracks in the foundation, replaced/sistered sagging floor joists, etc. and I believe my last step in structural additions/repairs is to prepare the previously unused attic to be used for a master bed/bath. Everything is on 16″ centers.

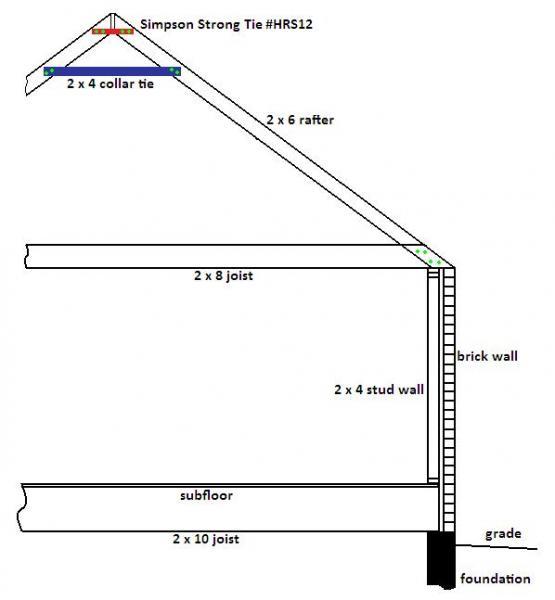

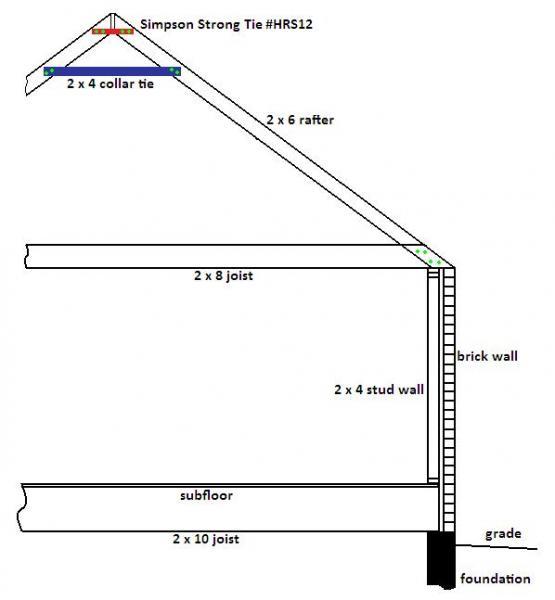

We will call the main floor ceiling joists 2×8’s, although their actual nominal dimensions are 2″ x 7 1/4″ (strange to me, but I don’t know much about lumber in the 1940’s). They are toenailed to 2×4 double top plate interior walls and also bear some on the top course of brick. The roof rafters are 2×6 lumber also toenailed to wall top plate and side-nailed to the ceiling joists. I don’t think this has any effect on things, but there are no soffits on the house, just a 1″ overhang of roofing materials, so there are not any birdsmouth notches, just slanted cuts. The roof pitch is very close to a 13′ run to 10′ rise, (actual size) which yields about a 16′ 6″ LINEAR rafter. There are 2×4 collar ties lapped and side nailed to every rafter pair. They are approximately 4′ long (between the rafters w/o the lap included) and located 2′ below the ridge. The ridge is not a structural ridge beam, it is just a 1×6 with the rafters toenailed to it and to each other. The ends of the rafters line up really well. Oh, and the proposed roof section to undergo changes is 25 feet long (ridge length).

I’m going to do a sealed (non-vented), exposed-beam, cathedral ceiling with closed-cell foam insulation to get around R36 in 5 1/2″. I would really like the look of the ties as double 2×6’s sandwiching rafter pairs. These would be bolted through instead of nailed. For aesthetic reasons and to make drywall a lot simpler I would like to “conventionally tie” only every third rafter pair. I would keep roughly the same vertical location and length. I would then use solid 2×6 blocking from each tie to the next, through the two bays to help eliminate twisting because of the collar tie removal. To keep the roof from opening up in high winds though, I would install something like this Simpson Strong Tie strap to join every rafter pair directly underneath the ridge board:

I’m not sure if the original design lessened rafter sag due to snow loading, or if it was just to keep rafters in line and to keep roof from spreading at the ridge since the joists are keeping the roof from pushing on walls. To help with the snow loading issue, I also am planning on building knee walls at a height of 4′ which would put them about 5′ 6″ in from the eaves, leaving a room width of around 15′ between knee walls. If my thinking is correct (BIG IF!) this would help with the rafter sag if I install the knee wall studs as compressive members, tight fitting, in other words.

OK… there it is. I am sure I left something out. At least one something, so if anyone needs clarification before pondering this, please let me know. Judging by previous posts, you guys are not going to pull any punches, but please feel free to pick this apart. I could maybe guess on the wood species and grade if anyone needs it, but I haven’t seen any stamps

I certainly don’t intend to ignite terminology riots, so if anyone feels I have mis-named something please try to educate me. ANY clarification would be MUCH appreciated. I have attached a drawing of the whole mess, my proposed additions in red, removals in blue, nail locations in green dots, bolts in yellow.

I am wondering if the plan above is acceptable, in whole or part, from the ties to the straps to the knee walls, so have at it!

Oh… and no inspections/permits/IRC dilemmas, just worried about CORRECT, SAFE work that will last. Anything worth doing is worth doing right! Right? Right.

Regards, and thanks in advance to everyone…

DB

Replies

spliced/fastened well... i'll check the sag tonight

DanH...

thanks for the speedy response!

first answer:

the rafters are nailed to the joists with some pretty beefy nails. not sure of the exact type but i can see tips coming through on each side. There looks to be about 3 nails in each direction. 1 1/2" 2x6 + 2" joist + 1/2" tip, and the heads are around 3/8" dia. so i would guess them to be 20d?

the joists are spliced in the center with 24" long plates made from 1x8, one on each side, and they are peppered with nails. i count around 5 per side, per foot = 20 per splice.

second answer:

i will get a string line on a couple of rafters tonight... but my eyeballs tell me it is really good, they have been known to lie to me, but not very often. i will let you know...

thanks again!

hope this helps everyone

DB

Well, I really don't think that's going to work.

FWIW, I'm doing a similar project right now: Preparing an attic space to be a 2nd floor.

If your attic is 26 feet wide (13'+13') x 25 feet (ridge plank) long, you will need some good mid-span support. That requires interior bearing walls and footings suitble for a 2nd story. Some engineering needs to be done here.

No matter what, you can't do a floor with those 2x8s as they will be undersized. Depending on where the midspan supprot is, you might be able to use 2x10's as the floor joist for the attic... but you can't cut off the corners so they fit under the roof. I think you will have to raise your roof to sit on TOP of the new platform that your new floor joists will present.

yep... i left stuff out!

xxpaulcpxx...

Okay, in my original post i didn't mention that i am not at all concerned with first-floor bearing. The longest span on which the 2x8's would see live loads is 14'. For this section i sistered the old dimensional stuff with new fir-hem #1 joists. All the other spans are 12' or shorter. Also, the bearing walls on the first floor sit on cinderblock walls layed on footings in the basement. The attic situations are the only ones in question.

Thanks!

DB

rafter bellies are minimal!

DanH...

As promised, I put the string to several rafters in the house tonight and found most were only sagged by a string width or slightly more. 3/32" on average if I had to put a number on it.

I did find one that had about 3/16" of a belly, but all the others were well under the 1/8" margin. Pretty good in my book... What do you think?

DB

and the knee wall verdict is?

Thanks DanH...

I think i will be just fine going ahead according to my plans, but I'm a step or three away so I can wait for more comments to come in (if they do).

In the meantime, what do you think about slightly pushing each rafter up with the knee wall studs? My only concern is; during high winds, the roof probably will flex a little, right? Do I want the walls compressed so much already (by jacking the rafters up during knee wall construction) that there may be noises or other adverse movement/energy translations during slight roof lift or fall? Maybe it's negligible, your thoughts?

Thanks for your time and expertise!

DB

Chuster

Do you have any concerns with the added load applied to your joists with these pushing up kneewalls?

And don't forget-know where the ceiling is when you walk around. I've worked in many kneewalled borrowed spaces and I understand why our code officials here will not allow anything under 5' high to be considered liveable.

Put a hat on and the condition is even worse.