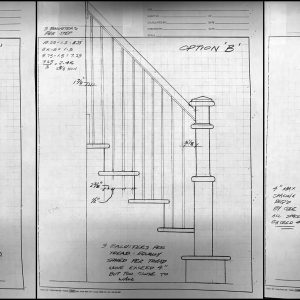

I am installing a new newel post, rail, and balusters. I used two balusters per step and laid out the two and three balusters per tread as typically calculated. My problem is that at each end I exceed the 4 inch maximum code spacing. What would be the correct solution to my problem. I attached a sketch with three options. Thanks for the help!!!

Discussion Forum

Discussion Forum

Up Next

Video Shorts

Featured Story

Self-installing an HVAC system requires a lot of thought and planning.

Featured Video

How to Install Cable Rail Around Wood-Post CornersHighlights

"I have learned so much thanks to the searchable articles on the FHB website. I can confidently say that I expect to be a life-long subscriber." - M.K.

Fine Homebuilding Magazine

- Home Group

- Antique Trader

- Arts & Crafts Homes

- Bank Note Reporter

- Cabin Life

- Cuisine at Home

- Fine Gardening

- Fine Woodworking

- Green Building Advisor

- Garden Gate

- Horticulture

- Keep Craft Alive

- Log Home Living

- Military Trader/Vehicles

- Numismatic News

- Numismaster

- Old Cars Weekly

- Old House Journal

- Period Homes

- Popular Woodworking

- Script

- ShopNotes

- Sports Collectors Digest

- Threads

- Timber Home Living

- Traditional Building

- Woodsmith

- World Coin News

- Writer's Digest

Replies

Unfortunately I can't make out the dimensions on your pic.

One thing that might work would be to use a slightly larger baluster.

Thanks for the reply. I am locked in to the 1/2 inch wrought iron balusters, so I have to work with it. Thanks again.

I can’t really make out your numbers as they’re a bit blurry on my end, but code allows 4 3/8” max spindle spacing on stairs (landings and floors have to be 4”), don’t know if that helps. Also, you can move newel location slightly to make it work. I typically start by laying out the spindles to match tread width dimensioning and then locate the newel according to the spindle location. Also, building code does not require guardrail within 30” of height off of the floor, so my inspectors disregard the guardrail requirements the first couple steps anyways as fall protection is not a concern (your jurisdiction may see it differently). Handrail has different code requirements however and needs to be installed all the way to bottom riser, but I’m assuming you will have a handrail on wall with your stair railing acting as a guardrail only.

Thanks for the reply. Option 'A' has a 5 1/8 inch clear opening between the baluster and Newel post, and a 5 1/4 inch clear opening at the upper wall and baluster, both exceeding the 4 inch code clear opening. I like your idea of spacing the balusters prior to fixing the newel post location. However, the lower tread nosing of the original newel post was already cut, so I had to work with that location. Thanks for the help.

Go back and re-calculate, but first project the top (narrow part) of the bottom post as the endpoint.

Thanks Uncle Mike. Ultimately, I went back and did exactly what you said. Being a rookie at this, initially I measured from the wider lower part of the newel post. Later, I remeasured from the wall to the upper narrow part of the newel post (measured 32 inches). I think I will go with Option 'B' the three balusters per tread. This will provide a 3 1/8 inch clear opening between the baluster and newel post, and a 1 7/8 inch clear opening at the upper wall and baluster. Thank you for your help.

It looks like you need to push the baluster spacing further back on the tread. I've encountered this in the past when the upper open tread is partial.

Thanks for the reply Andy. I tried doing that by bringing the top baluster at the wall closer to the wall to close the gap, but it resulted in increasing the gap at the lower newel post, or causing it to be too close to the nosing. I think the only solution, given my existing parameters, is Option ‘B’. The balusters are tighter spaced but it looks good, I laid out a few temporarily to visualize it. Thanks for you help Andy.

Glad to chime in.

This is how I lay out balusters.

Thank you Joe.