What’s an easy clean way to cut Vs in the bottoms of thes 2×2 balusters ? I guess I’d use my radial arm saw and make two passes, but unless you’re exact, you leave an overcut on one or both sides. This is probably the best way but I thought I’d ask. Got quite a few to do.

Replies

Tablesaw. Tilt and raise blade to exactcenter of baluster. Attach sacrificial fence and bury the blade to where the tips of the blade teeth, fence, and table all meet (will require bringing the blade up thru the fence.) You should be able to put the baluster against the fence, run it through, rotate it 180 degrees, and finish the vee. Repeat however often until you are finished, or just bored.

Or maybe someone else has a better way.

"I am the master of my fate, I am the captain of my soul." Invictus, by Henley.

Joe,

Are they all exactly the same dims? The ends are exactly square"

If so, set the table saw to the angle you want, set the depth so that the top of the kerf is the same height as the centerline of the baluster. Better to be high than low. High won't interfere with the fit, just give ya a little venting for drying. (|;>)

Set the fence so that your kerf is just in from the end.

Cut, flip, repeat.

Fine tune the angle and depth. Cut 'em all and let the carpenter sort 'em out.

Oh. Wait. Yer the carpenter.

Cut the other ends to length.

SamT

Just thinking out loud, but maybe tape/clamp 10 or so together so all the bottoms are flush and facing up. Then make a jig so you could run a chamfering bit across the bottoms all at once. May have to make a few passes depending on what kind of router, and how much material you are removing.

Or cut them one at a time on the band saw. Clamp a speed square to the table as a 45 degree fence, and a stop block to control the depth.

I think the table saw is going to make a projectile out of the cut off piece.

If I run the balusters veticall thru the T saw, the blade won't tilt over that far. Doing it horizontally, I could rig up a sliding table, but, I don't like leaning over and cutting on the T saw, and launching projectiles ..

I like the bandsaw idea ..

What if you cut a square mortise into the bottom piece, and just slid the square ballister into it?

Router table and a dovetail bit.http://www.lesvisible.com/

Doing it horizontally, I could rig up a sliding table...

I was thinking miter gage, myself, end against the fence. Zip-zip, on to the next.

"I am the master of my fate, I am the captain of my soul." Invictus, by Henley.

I think Bill has it, because you can also then rip the bevels on your bottom rails, exact match .. just set the blade to 5 deg and away we go !

you get a dawg bisket BillW, good boy !

woof!

woof!

woof!woofwoof!!

I just did about 70 of these - used a variation on the tablesaw method already described, but rather than a sacificial fence, I used a spacer - a small block against the fence before the blade, stacked 5 balusters at a time on my miter gauge (pushed up against the spacer block ), slide past the block into the blade, set to come up 1/2 way through, then flip & repeat.

BTW, I left the blade set at this angle, raised it to go 1/2 way through a 2x4, then ripped the bottom of the railing assembly to get a perfect match where the bottom of the spindles hit the 2x4.

BillW is right on. that little spacer at the front of the fence makes for a safe operation. I don't stack 'em though, I find it less stressful and just as fast to do them one at a time -- cut, flip, see ya later. cut them to length after you've made the trickier bottom cut. it's also easy to mark and drill perfectly spaced 90 degree holes in the bottom rail -- install your first balluster (I usually start in the center) with a spot of polyurethane glue and a stainless screw from underneath. your eyeball will center the screw just fine sideways while the groove will center it on the rail. then a small spacer block will tell you where to set your next ballusters in both directions.

Got to wondering how Dino would do this?

R-EZ.

Two cuts. Set all the balusters under the EZ and cut.

You need to build a lay out table top like this one.

.http://www.eurekazone.com/images/gallery/multiplecutlayouttable.html

We need to place the balusters square to the table top and the guide rail square to the balusters/tabletop.

Rez. You knew that.

YCF Dino

I would use your RAS.

I would use your RAS.

That'd be my choice.

I'm inclined to think that a jig - 2 parallel 'tracks' with the bottom rail between (with the spacings well marked), upon which runs a carriage supporting a router. Set the router bit to remove only sufficient lumber from the rail to take the 'foot' of the baluster...3 passes with a 1/2" bit. Bonus being that the balusters won't wiggle when you place them.

Once the jig is made, you've got it for as long as you want.

ciao for niao

To those who know - this may be obvious. To those who don't - I hope I've helped.

Shaper or moulding head; use a tenoning jig to hold the balusters upright.

Dinosaur

A day may come when the courage of men fails,when we forsake our friends and break all bonds of fellowship...

But it is not this day.

Well, my first choice would be to use the RAS to cut shallow dados across the base; but, if you have your heart set on notching the ballusters instead, use the RAS. Make a jig (just two sides of a box with a stop-block for length) to register the 2x2's in the same place everytime.

Phill Giles

The Unionville Woodwright

Unionville, Ontario

I'm still inclined to use the t saw, and then bevel my bottom rails to match ..

Joe.

You have the guide rails. This is the best application for the system.

The wood stays under the guide and you just slide the circular saw on the track.

Use the outer groove on the smart base.

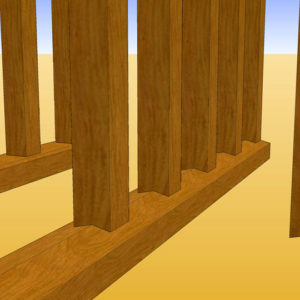

Take a look at this picture. If you bevel your saw and you use the outside track on the smart base, you can cut 50 pieces at the time with your system.

The job is done in few minutes.

View Image

Edited 8/20/2005 8:52 am ET by dinothecarpenter