Deck questions-sonotubes, concrete hardening time, post to beam connection

Hi.

I’m building a low free-standing deck

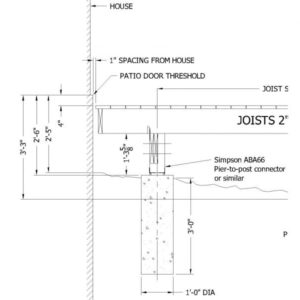

I am going to pour 6 pier footers for a deck I’m building. I’m required to go 36″ below grade. I will be using those sonotube forms, 12″ diameter ones. I was going to cut each tube to 36 inches (they come in 48 inch lengths at my local Lowes).

Someone told me that I could dig the holes to the required depth of 36 inches but just cut each tube to 24 inches. I’d save money this way by only needing 3 of these tubes instead of six and there’d be no waste cutoffs. They are about $12.50 dollars each for each 12 inch diameter by 48 inch long sonotube. So I’d be saving myself around 39.75 dollars or so with tax.

Can I do this?

The tops of each of these footers will just be slightly above grade.

Also, how long do I wait for these piers to harden before I can drill into the tops of them to attach my adjustable metal pier-to- post base connectors-like those made by Simpson ABA66 or USP.

I’m following the same method used by Rick Arnold’s column in Finehomebuilding mag issue “Decks and Outdoor Projects” Summer 2010 to make these piers.

Also, I’m using 6 x 6 posts with a doubled 2 x 12 beam resting on top. What is the best way to make that connection between these sizes of lumber? A 6 x 6 post is actually 5 1/2″ square and a doubled 2 x 12 finishes at 3 inches. Do I use a Simpson post to beam cap that can handle a 5 1/2″ square post but then do I put a spacer between the doubled up beam to get to the 5 1/2″ dimension? Or do I notch the post and rest the 3″ thick beam in that? I believe the IRC code (which my township follows) does not allow the beams to be fastened to the sides of the posts with just carriage bolts drilled throught the post and beam.

Also, should I just remove the post shown in my attached file and lay the beams onto the tops of the concrete pier since the 6 x 6 post is so short?

Thanks to all in advance.

Replies

Pizza

Take a look at each of these post connectors that simpson offers. You might be able to use them for your beam to pier connectors. Some you embed in the concrete at the pour, others might be bolt or epoxy down.

Also, some are adjustible to fine tune the height (if they work for your intention.

You would still go with the 4' tubes, but there'd be no short post (depending on the height you need.

http://www.strongtie.com/products/categories/post_bases.html

Eliminate the short 6 x 6 ?

Hi. So, your saying that I could eliminate that short notched post and use something like the ABU44 Simpson connector to attach that double 2 x 10 beam directly to the top of the concrete pier?

The opening in that connector is 3 9/16" according to their specs. Since my double 2 x 12 is essentially 3" thick, does that mean I'd need to place spacers in there to fill that 9/16" of extra space? If so, can I just place two 9/32" thk pieces of PT wood to either side of my centered beam in there and be OK?

Pizza

I might ask an inspector or contact simpson...............

but, a short post would seem to provide little room for the proper connecitons of post to pier and post to beam. You'd be making swiss cheese out of that thing securing it.

If they wouldn't allow crussification of the bracket to bring it in a 1/2", then maybe spacers are the ticket. I'd stay away from wood if possible at the bracket (which seems the simplest of places to shim) and use pvc out of my pvc scrap pile. Won't hold moisture, not going to promote rot, etc.

A Roob Goldberg approach might be to through bolt it (is the hanger allows it and use stacked washers or a nut on each side to be you shim.

But again, run this by the inspector, he's going to be the king of decision making. Simpson might be eqaully helpful-they've got a thousand different types of connectors and brackets..........................and know a heck of alot more than we do about them. While the catalogue is pretty good, it's easy to miss something.

The purpose of the sonotube, in addition to making things look nicer and keeping the hole from collapsing, is to make the sides of the pier smooth so that one doesn't experience "frost pull" that slowly extracts the piers from their holes. It probably is true that you can get away with only 24" of tube in a 36" hole, but then you have to worry about the bottom of the hole collapsing, and keeping the tube at the right height as you pour. And you have no extra to stick above ground, or to "play with" so that you can get all the piers to come out at the same height.

Lifting a short sono to top of hole is fine. You get a "fist" down under the soil that resists upheave from frost.

But don't think it will save you money, as you will use more crete then.

Don't forget your rebar.

no need to dril into to crete. Have the hardware on site and placed it in the resh poured crete.

Eliminating te posts would mena doing everything else with greater precision than it appears ( from your limited experince implied) you have, and executing precision is expensive amd time consuming. You have to be precise in al three dimensions at once

Sonotube for deck

Ok thanks. I'm going with a 36" sonotube for each pier.

All of the Fine homebuilding articles I've collected on deck building don't mention rebar in the concrete. How long, how many, what shape per pier?

Their collection of articles called" the Ultimate deck Guide" doesn't mention them.

How much rebar depends on size of the tube form.

6-8" just use one #4 right n center

12" I prefer three #3 tied together at top