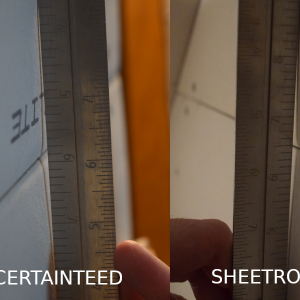

I’m putting up a lot of drywall. I’ve been getting certainteed lite from a local building supply place but had to pick up some sheetrock brand stuff from a home depot when my usual source was closed. The sheetrock is mostly alright but there seems to be less taper on the finished edges. They also look a little tapered at the very edge on the back. There are a few edges that are even less tapered than the others.

The certainteed isn’t perfect either, the back is all wavy, but at least it looks like the tapered joints will finish easier. I’ve got a photo attached showing both for comparison. Is this normal or did I get some lower quality home depot version? Is the sheetrock defective? Should there be more taper or is this fine?

Replies

That's plenty of taper. You don't need much space for the tape and topping compound. Actually, a smaller taper makes taping/spackling go faster, since less mud is needed to fill.

nmc,

You reminded me that I’ve handled, hung and taped thousands of sheets and I don’t think I ever checked the taper. Thinking of that I just got hungry, tired and sore.

Thanks.

The sheetrock brand boards also have a sharp tapered edge corner where the paper wears down in shipping. It can pop and stick up when you screw down the board near the edge. What do you do for that, cut off the raised bit of facing paper and re-screw farther in?

Not sure of what you speak but,

Screw it, tap a mushroom flat if present, keep a utility knife handy and if you think it necessary, cut away loose paper.

again but, you might be overthinking this whole thing. You can’t make rocket science of drywalling. Usually pretty forgiving, “let the finisher worry about it” was the usual cry from goofballs. However, those that hang and finish know the parameters for a good job.

You got a picture?

It would be hard to capture in a photo. The note of the tapered edge on the sheetrock sheets is really square and crisp, unlike the certainteed ones which are rounded. The paper can get worn down along that square edge so it sometimes snaps along there when I drive a screw nearby. Now that I have the panels butted up against each other on the wall, I can barely see it so I'm sure it's not a big deal.

How close to the edge are you placing the screws? I don't like getting less than maybe 1 inch, preferably more. Its all going to get taped/spackled over, so IMO there little sense in placing screws too close to the edge

The taper is fine.

You’re missing the whole point of drywall, you find an excuse for your bad tape job AFTER completion, not before!