So … as the slowest builder in the world, I am finally ready to start the roof!

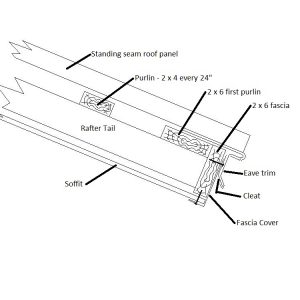

I am putting on a standing seam roof.

Most of it makes sense but I do have a question about the fascia.

The trusses have a 2 x 4 tail.

I have decided to go with purlins rather than sheathing on the roof … just a lot easier to get 2 x 4’s 30 ft in the air rather than drag 150 sheets of wood.

I am going to use a 2 x 6 for the actual fascia.

I “think” I need to fasten the soffit to the bottom of the fascia (the guys on my house used F channel but I see most guys on youtube just fasten to the fascia).

I will then put a steel cover over the fascia and it will cover the bottom edge of the soffit.

I am using a “cleat” to give some extra hold to the eave trim (that the metal roof bends over). The factory says the cleat adds a lot of strength in high wind areas.

So my question … how to fasten the fascia cover and the cleat.

The instructions from the supplier show a screw in the cleat … but it does not show any details on the fascia cover.

Can I use the same screw to hold the cleat and the fascia cover.

Or put the screw high and just slide the fascia cover under the cleat.

Or ????

And then maybe a screw in the bottom of the fascia cover (I can use stainless screws)?

Just not quite sure how to do this.

Attached is a picture of what I am thinking about.

Also a picture of the shop.

Thanks !!!!!!!!!!!!

Replies

I hope that you recognize that the standing seam metal roof panels expand & contract with temperature changes. A 25' long steel panel can grow (or shrink) as much as 0.146 inches over a 75°F temperature change. This type of roofing is usually fixed at the ridge and free to expand & contract at the eave. All intermediate clips attaching the panels to the roof are such that the roof panel can "slide" up or down the roof as needed. 0.146" may not seem like much, but it can cause the panels to buckle between your purlins if they are firmly attached at every purlin.

Hey!

I have never even seen a standing seam installed ... never mind doing one myself.

That said, I read the complete installation manual cover to cover and watched video after video.

The panels are about 36 ft long ... that is actually my biggest worry ... getting them on the roof without bending them.

I did read all about expansion. They even tell how much room you need to leave at the eave end depending on the temp you install them.

With the purlins "on flat" ... and my roof being very flat, I think I will be OK.

The manufacturer recommends putting one single screw at the top ... then clips along the length ...then folding the bottom edge over the eave trim.

In my mind ... being a single man build ... I had the option of hauling up 150 sheets of plywood and 150 bundles of shingles ... or 2 x 4's and long but light panels of steel roofing.

Plus, I had the roof quoted by a couple places ... $40K for sheeting and shingles ... $60K for sheeting and standing seam.

The material for a standing seam will cost me less than $20K delivered ... big difference in my pocket book.

Should be an interesting challenge!

Mike

You might want to find a job in progress and go watch it being put up.

decking and conventional roofing has way smaller parts and more forgiving installation.