I’m building a new fence next weekend and could use some advice on the rails between the posts.

I’m using 4×4 PT posts, spaced 8 ft. The fence needs to look good from both sides, and I was going to use (2) 1x4s as rails, sandwiching the 1×6 vertical fence boards. 1×4 rails so it provides a nice shawdow line (5/8) on each side. I’d toenail the 1x4s into the posts. A 2×4 rail might be more sturdy, but the fences wouldn’t look symmetrical.

What are your thoughts? Would the sandwiched 1×4 rail – 1×6 fence board – 1×4 rail provide equivalent support to a 2×4? I’m wondering about the strength of toe nailing a 1×4.

Or, would the asthetics not be so bad if I put a 2×4 rail on one side and 1×4 rail on the other?

Thanks guys.

Replies

No need to worry about the 1x4s being stout enough, since the toenails will pull loose in a month or two.

8 ft centers push the 1x4 limit.

I try not to go that far when working with 1x4 or 6. I'm going to try and dig up a picture of a fence from a couple yrs ago using narrower pickets.I might be able to guess at the post centers from it. I know the rails still run true

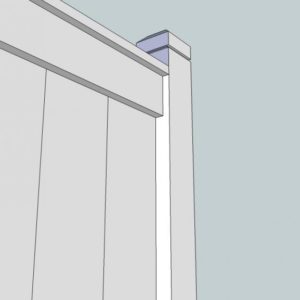

Whelp, here's two pics. I'm remembering them being not 8' apart, but getting into those trees-they might stretch 7'. Notice in the first one, I used a small block the thickness of the pickets-predrilled and screwed to the post. The rails then were toescrewed to the post. I made up the sections with rails on one side only, placed against the blocks and clamped-screwed to the post. The block-gave me something to go to for height and kept the next rail I added apart from the first side.

I stainless stapled the pickets to one rail. Placed that in position and fastened to the post. Added the outter rail, spot stapled and then screwed through to the other rail-one side only.

Remember, treated has a mind of it's own while drying.

Calvin,

That's exactly the detailed construction that I planned. I see that you used 6x6 posts though. I planned to use 4x4s for cost reasons, but I like the beefiness of the 6x6. Did you use 2x4 or 1x4 rails on both sides of the fence?

1x4 for the rails.

And I had the homowner have a fence co. put in the posts (scary thought-but I set stakes where I wanted them and damned if they weren't plumb and straight in line when I got there!).

They were 8x8's however-we wanted to "match up" with the size and "style" of a cedar fence I did for the hot tub area along with the front porch.

These pictures are huge, but you might be able to make out some details that tied it in with the others. The other "fences/railings were made out of cedar-built up for the 7'' posts. Much easier to work with. The back fence I had to replace a couple pickets that MOVED quite a bit.

Ken,

The post depth is up to you. But, these considerations are important.

Frost, wind, and lateral loading.

Frost depth-If not down far enough, frost and frozen ground can push up and then let slide down at different levels. Movement like this ruins a good job. Imagine looking at your perfect straight or stepped line one year and the see a fence line that looks like musical notes.

Wind pushes on a privacy fence because it has no where to go-can't be relieved by passing through open pickets (which even they feel the force of wind. This loosens the posts in the ground and/or puts a strain on the fasteners.

The wife wants a bunch of hanging baskets on nice arcing hook brackets attached to the posts. "yes dear", but the weight over time will pull the fence over.

Depending on your frost line, I would still go down 3' for long term performance.

Thanks for the complement.

As much effort as you're putting into this fence the posts should be down 2.5 or 3 feet. Two feet and the fence will be leaning in a few months.

Thanks for the advice, guys.

Now, does anyone want to buy (25) 6x6x18s??? ha

I know you can go to the big boring box for short material

and it's easier to haul................

But, check out local yards or even fence companies. They might/will have posts alot longer. If you are in good shape, courteous and lucky-pick out big ones that might make material yeild a bit better.

I coat the ends of my cut posts going in the ground with black roof goop to seal the cut from water entry. Or, and even in addition to-put the uncut end in the ground and coat it too.

Locally (Charleston, SC), a variation on what you have described is quite common. The panels of a fence are lateral stringers along the top and bottom of the panel (on both the front and the back) with nominal 2"x2" (real 1.5" x 1.5") pickets spaced out on about 4"-5" centers. The sandwiched construction is plenty strong, and gates don't normally sag (if a reasonable 4' or narrower passage).

The size of the panels you mentioned (8') seem really long for 1x stringers. I would strongly suggest using 1x4 materials on the front of the fence with 2x4 materials as the rear stringer. Locally, the front stringers are often done use beaded lumber. (That is, a rounded slit has been cut along the edge of the stringer to give it some visual interest.)

As I read your question, you seemed to be concerned about using two different dimensions for the stringers on the two different sides. But, you'll never be able to see both sides at the same time. Assuming you don't buy really cheap 2x4 materials, the beefier stringers will look fine. (I don't know of a source for beaded 2x4 materials, but you could run a router along the edge to cut your own if you wanted to match beaded materials on the front.

The strength of the fence can be ramped up by using pocket screws to join the panels to the posts. The first reply suggested that the toenails would pull out or weaken. That might be. But with 2x4 rear stringers, you can easily use a pocket screw jig to secure the panels to the posts with 4 heavy duty screws (two on the top 2x4 stringer and also two on the bottom 2x4 stringer).

I am assuming that you probably went ahead and built your fence many years ago, but I wanted to actually provide an answer to the question you asked for future readers.

“[Deleted]”