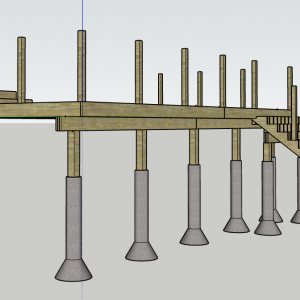

I’m in the process of planning a deck that I will be building at my house. A 3d sketchup model of the deck framing (including footings) is attached. I can post a version with all the trim and decking as well if anyone wants to see it.

Following Mike Guertin’s recommendation at the link below, I plan to use a frost-depth (5′ in my area) footing to support the base of the stairs:

The very thorough article on footings (linked below) also suggests that this footing should be formed in such a way that it has smooth sides so that the surrounding soil can slide freely against it with frost heave:

https://www.finehomebuilding.com/project-guides/decks/deck-footings-done-right

That probably means constructing some kind of a box to act as a form and then stripping the form afterwards. But I’m at a loss as to how to do that without digging a massive hole (i.e., replicating the way a basement foundation wall might be formed). The stairs are 7′ wide (so that people could sit on them without blocking access to the deck).

Hoping someone has experience with this or ideas on how to do it.

Thanks in advance!

Replies

Just doing two of these for 48" wide stairs and my engineer spec'd an 18x52" rectangle 30" deep (frost around here) (it was a lot of bags of concrete!). Earthen form was fine acc. to both him and the inspector and I was able to make the soil sides pretty smooth

Thanks that's helpful. I was thinking I might be able to line the sides of the hole with something that would keep the footing relatively smooth...maybe corrugated plastic sheets? ...I'd just leave the sheets in place after the footing's poured.

How did you dig the holes? I'm planning on renting a mini-excavator with auger attachment to dig the footings for the deck beam. Wondering if digging a few holes with the auger close together could speed up digging the big box under the stairs.

This is not always required, but we seriously recommend it. With frost footings in place, you can use a concrete anchor, base apkstick.com plate, and short post in order to create a solid ground connection. A 3' x 3' level landing area is required at the base of all staircases.

Fine Ditchdigging:

It is frequently easier to square off a hole than to dig from the top.

Specifics depend on soil structure and moisture level.

One thing to keep in mind is the danger of a cave-in. Plan your excavator hole sequence to keep the weight away from empty holes. Last thing you want is to have a cave-in when your head is stuck down a hole.

A shop vac can be a help to clean out the bottom of a hole. I have been known to tape a couple hoses together to allow for extended reach.

"Fine Ditchdigging" ...I like that. :-)

...at least it's a change from "Fine insulation and air sealing" though right? ...FHB podcast humour.

Thanks for the advice. I am a bit worried about cave-ins. I planned to wedge some 2x4s against the sides of the hole to brace it while working inside and then remove them just before pouring.

For the excavating sequence, the plan is start with the furthest hole and back the excavator up to make each subsequent hole so the weight of the excavator is on untouched earth...then go park it away from the hole before doing the shovel work to square the the holes.

another shopvac user! People think I'm nuts. My inspectors all have loved seeing the photos. Plus making sure there's 3" of clearance to the rebar , finding out you've got 2" in one corner, but everything is in place in a 5' deep hole, and that shop vac is a whiz at cleaning out that corner.

Utility crews use vacuum trucks all the time to remove material from a confined space. Shop vac is just the little cousin.

Gosh, that seems like a lot of digging and concrete. I'm admittedly not familiar with frost requirements so severe but couldn't you just pour a couple piers and use ground contact posts and beam? Just wondering?

Something like this.

In my area, ground contact 2x material isn't readily available. Also I would expect that even ground contact rated 4x4 or 6x6 will eventually rot out and then it would be quite difficult to repair (i.e., need to excavate out all the rotted wood).

I thought about perhaps just using a beam across some concrete footings and securing the stringers using regular joist hangers. It's basically the same idea as this but avoids putting the lumber in the ground.

Anything that Mike Guertin says, I hold in the highest regard. That being said, frost depth footers for stair landing are not required by code...(in my area Denver CO).

This article has a great summary of the issue( although it is 10 years old)

https://www.jlconline.com/deck-builder/deck-stairs-on-frost-footings_o

If you want to use some frost depth footers, great. I have in the past, but do not anymore. I would put that time and money towards some cool lighting or better decking.

I read that article myself before posting. The hinger/lever action at the top of the stringer connection is what I'm concerned about. I suppose I could inspect it regularly. The soil in my area is mostly clay and tends to hold quite a bit of water. Plus we get seriously cold winters up here in Ottawa. So frost heave is a pretty serious concern here.

But I was thinking today that there's an easier option - a frost protected slab. I started thinking about this after doing the calculations for how much concrete I would need...it's way more than I can handle on my own.

Still working on the details for the frost protection (e.g., how much insulation, how far it needs to extend out, etc.) but it seems like this would avoid a lot of back pain while still giving me the frost protection I want:

https://www.finehomebuilding.com/2010/11/11/frost-protected-shallow-foundations-2

Patrick1,

Its probably just as easy to do what you were thinking in post #9. https://www.jlconline.com/deck-builder/single-ply-beam-solution_o

Ive done that as well and it does feel like a nice way to do it. I didnt use hangers though...