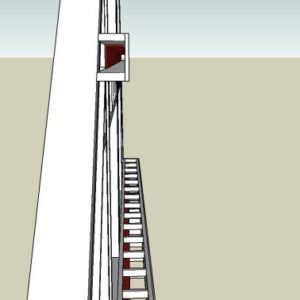

You regulars may recall the Q I raised a while back about how to handle this. It’s a simple 24-foot-tall two-story gable end of a small house, the wall having no intermediate floor connections. One big ceiling vault inside, and the wall is mostly glass.

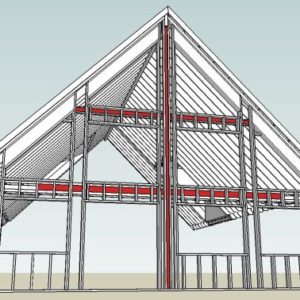

Well, my steel engineer and I have been swapping ideas, and here is where we are tonight. See the pics.

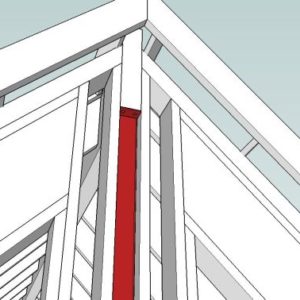

This pic shows how we’ve sandwiched a section of 3.5″ square tubesteel into the tall middle, to pick up the roof loading coming down from the 3.5 x 18 structural ridge. You can also see the two unequal leg angles that bolt to the structure from the inside, to provide some wind bracing. The tallest 2x6s needed are from 24-footers, in stock at the yard.

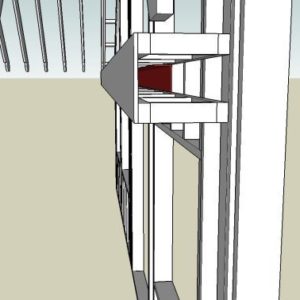

Here is a view looking into the detail framing (2x3s and 7/16 OSB) that houses and hides the lower 6×4 angle windbrace. This “canopy” feature will house downlights to give some perimeter lighting in an otherwise poorly-lit greatroom.

This view shows the trim feature for the top windbrace angle, a 4×3. Smaller than the one across the bottom windows and sliding door, this little boxout will be a mount for an uplight array using Juno Trac 12 low-voltage strip lighting. A continuous reflector strip will aim the light up and inward to bounce off the ceiling.

Finally, this closeup shows the connection at the top of the tubesteel column, where it is picking up the two-ply LVL. We’ll stick a rip of 2″ rigid foam in that cavity and foamseal it, so our steel won’t transmit so much heat outside. In this view, you can also see the end of the big “channel” headers for the top polygonal windows, made using 2x6s and rimboard. The board is just to take up space and save us from chopping a bunch of skew crips and then wondering why we didn’t give ourselves better nailing for our siding. These window openings under the gable end don’t have any roof load coming down, and thus really don’t need much in the way of headers.

All in all, I think we ended up with less than 460 pounds of steel, total. Not too bad.

Replies

Nice Gene! I love those drawings in SU too. Will you post pics of the framing?

About 10 years ago we framed a house for an engineer and he was doing what you are doing, but without the steel. The walls weren't real tall but he had us frame a box a little higher than middle with 2x12s on edge to keep the wall stiff.

Thanks, Tim. Re SU, I upload for sharing, many of the models I do, so if you have and use the software, you can go to the "get models" site and view and download them to your PC.

The "components" libraries SU has assembled, contain sections of just about any wood or structural steel member you can think of.

We'll wish we had all your rafter cutting gear when we whack those 2x12s. We don't do enough framing to make gang-cutting equipment cost-effective. One at at time, we'll whack and stack.

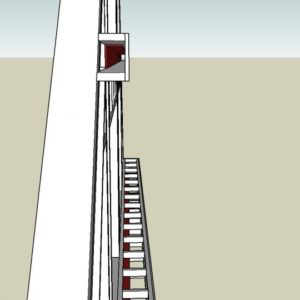

SU will be of value when we go to build the gable wall. We'll precut everything, and prebuild all the spandrel panels, then hoist and spike up all the kitted parts.

Photos? Sure, we'll take some.

Gene,

We don't gang cut all the time. If you get into a good rhythm and have all the math done, you can set up two guys with patterns, each with a saw and you'll get a lot done. That roof should be fun and quick for your guys to frame.

Can't wait to see the pics and thanks for SU comments. I forgot about the models and such.

Gene, where is the "windbrace".

blue

There are two, an upper and lower. Really, just horizontal wall "backbones." Unequal leg angle steel, shown in the pics.

Okay, I understand now. We use the term windbracing to mean diagonal bracing, which prevents racking. Your braces don't really do that. They are just stiffening up the wall to prevent bowing from the wind.

blue

Now that I know what you are trying to do:]

I think your wall will still be shaky. To prevent the shakiness, I'd add vertical stiffeners in the other two tall bays that separate the windows.

blue

Here is one, just a little smaller, but having the same thing going on. We whacked out the roof to add the shed dormer, late this past summer.

View Image

No shake at all.

Gene,

I sat through the short class about glulams put on by Rosboro at JLC LIVE, and they were showing glulam posts made for walls like yours. Did you give any thought to using them? Just curious.

I've seen paralams spec'd for that, too. Oh God said to Abraham, "Kill me a son"

Abe says, "Man, you must be puttin' me on"

God say, "No." Abe say, "What?"

God say, "You can do what you want Abe, but

The next time you see me comin' you better run"

Well Abe says, "Where do you want this killin' done?"

God says, "Out on Highway 61."

I'll have to agree with Blue. 3.5" sounds a litle light. It may be OK for Roof load but in my opinion lateral wind pressure is going to be your main issue.

Nice drawing though.

regards

Mark

Your drawings are awesome. You should be able to sell work quite easily with renderings like that.

I'm not sure why the horizontal steel doesn't run all the way to the corners. It seems like you'd pick up a lot of stiffness by doing so. Also, I bet you can substitute an engineered wood column for the steel, and possibly also for the horizontal bracing. It's a helluva lot easier to nail into.

Surprising that your clients want to pay to build and heat that tall space with no floor area up there to enjoy it or look out the windows.

I'm going to give the whole thing to the I-Level distributor's engineer, to see what she can come up with as an alternative to the steel.

I've a secret need for steel in the job, at least a little. I don't have a NY PE license. My steel guy reviews and seals my drawings for free, if I buy steel in the package. We need the sealed set in order to get the permit. Without a steel purchase, I'll have to pay my steel guy about $250 for a review and a seal.

Running to the corners just spends money, and doesn't yield much in the way of additional bracing. The sidewalls coming to the corners provide what we need there.

The owner picked the plan from a page in a plans magazine, so I just took it and ran with Sketchup. The wall of glass faces south, toward the southern range of the Adirondacks. The house has a second floor master BR at its opposite end, and the view can be seen from the top of the stairs, and also from in the bedroom, through interior windows that look south.

I'm not sure why the horizontal steel doesn't run all the way to the corners. It seems like you'd pick up a lot of stiffness by doing so.

I was thinking the same thing.

At some point though, a 6x4 angle gets very bendy, like a piece of spaghetti. I only remember them coming in 40' lengths when I worked at the steel supply yard but we could weld them togehter.

blue