Roof deck project coming up. Many thanks to who have advised me on the structure of the deck and how to protect the roof. My strategy is to pad all of my footers. Also I want to put down some kind of work surface to walk and work on outside the area of the deck. I was thinking of plywood sheets, but that’s a lot of area to cover. Any suggestions?

I have also found a crane company to drop the lumber up top, but I invariably need bring more lumber to the site. I am looking for a way to get the lumber up there after the initial drop.

Handy Dan

Replies

I'd use 1/2" high density fiberboard. Lighter , cheaper, just be careful to put some weight on it so it can't blow off.

A Reiman Georger platforn hoist would be perfect for getting supplies up there.

Maybe some rental yard has them to rent - kind of expensive to buy for just one job.

>> 1/2" high density fiberboard << What's that? You mean like Celotex sheathing also sometimes called black board? - that stuff that is actually made out of sugar cane stalks left over from the sugar refining process?

The same material used under a fully adhered rubber roof. No sharp edges , about 6 bucks a sheet , softer than osb underfoot.

Dunno if it would too light (you might spend more time trying to anchor it down than actually laying it out), but my drywall supplier carries 4x8 sheets of coroplast sheets. Z

Our suppliers regularly stock 50 sheet units of 12' drywall up to 50' high windows using a Gradall54. A good driver should be able to get some lumber up there for hand unloading fairly easily.

Mike

Small wheel turn by the fire and rod, big wheel turn by the grace of god.

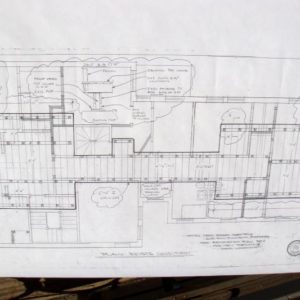

Looking at that plan it looks fairly extensive - an interesting project. Regarding protecting the roof, my first thought was 7/16" OSB as it is the cheapest sheet material available. Seems like you might only need a "runway" down the center and maybe a few other spots to have the crane set the material piles on... Seems like one of those kind of situations where no matter where you put the material, it is gonna end up in the way and some has to be moved...

Maybe have 2/3s of the material delivered, build that, and then have the rest of the material delivered, with just a little extra. That way, your second takeoff will be on a smaller area so there is a better chance of getting it right, especially since you have already built a good part of the project so will know material usage pretty close to exact. Also, your second crane rental can get rid of culls and most of the OSB from the first go round, and in the end, the little extra material you have can be lowered by a rope or some kind of rope and pulley arrangement.

BTW - maybe you can get the building supply to band up the material in small packages. Seems like a reasonable request...

Hope that roof is newly re-done. A leak would be hard to deal with... Are the deck boards to be screwed? Just out of curiosity, what material are the deck boards?

Hi Matt:

Thanks for the input. I think OSB is the way to go. We have used it on other projects and if it doesn't get too wet it can be recycled and used on the next site. It is a pretty big area, but we have to stay neat and be super careful about punctures. I'm thinking it might be good to lay down some tarps first and then the OSB on top to that in the major work areas.

It is around $1000 to get the crane, the permit and police detail, so I really can afford only one delivery.

We are not screwing down the deck. Instead it will rest on 2x12x12 pads which are cushioned by heaver roofing material. There will also be 8 anchors at 8 corners hold ing the deck from flying away.

Decks boards are meranti. Probably 5/4 by 6.

I really can't hire a small lift. I am considering assembling a scaffold. Our subsequent loads will not be that heavy, but will be long, like 2x10x16s.

Handy Dan

>> It is around $1000 to get the crane, the permit and police detail, so I really can afford only one delivery << That's expensive! Here I can get a boom truck for around $250 which would probably reach that, but then again, I never had to have one park in a busy city street and jump through those other hoops...

There are also trees in front of the drop zone so we need an especially long crane.

Dan

My roofing supplier will deliver OSB or plywood to the rooftop using their regular conveyor truck---absolutely zero problem-- of course you have to buy the sheet goods from them--and not your regular lumber yard.

stephen

Rent a telehandler!

42 foot reach is standard 56 foot reach is available on soome brands.

Please note that you will likely need more than 42 feet because you won't want to set every thing near an edge..

You can also use it for quick roof access and as a fall flatform should anyone take a spill.

Hi Frenchy:

Looks like a fun machine, but much more than we can afford on this project

HD

The back picture shows plenty of room to place a 4wd vertical manlift.

Get one with leveling outriggers and up ya go.

Might be cheaper than a crane... leave it there for a week.

I am looking at those Danski. I have to decide if the rental cost per day off sets the labor of assembling a narrow scaffold. I expect to be there five weeks.

Do have a product name for the man lift. Dan

The manlift will offset any OSHA issues due to an improperly assembled or used scaffold.

It will be difficult to get material up a scaffold in a safe and efficient manner. Moreso if the scaffold is narrow.

Most lifts have an extendable platform, so you could park the narrow end perpendicular to the building and extend out to meet the building. That should still leave enough room for a dumpster.

I would get a lift with proportional controls.

Gasoline/propane operation eliminates battery charging problems.

JLG and Genie are two big players in the lift arena.

Operators may need to wear a safety harness and tie off when passing materials from lift to roof. You would be wise to have the receiver on the roof harnessed up and tied off. Still cheaper than a crane and done on your schedule.

You make a lot of sense Danski

Right now I am looking at $1000 to crane all my lumber up to the roof. That is $750 for the crane company for three hours, $350 for permit and police detail. As I said, I spend a lot of time going back to the lumberyard for materials even after the initial lumber is dropped, which is why I need to consider how to get stuff up there after the big load is delivered. Which I may still do anyway as I think it is too much to move all of the lumber by means of the scissors lift.

There may be some wisdom in over ordering materials that are resalable to the lumberyard, then my worry will be getting stuff off the roof when the job is done .

Which seems to point to scaffolding or a manlift. Scaffolding will be around $800 for 5 weeks. Rental of a manlift? Not sure

Dan

a 40 ft rough terrain scissor lift will rent here for $2000 for 4 weeks. If you don't need it for all 4 weeks figure $660 a week plus delivery and pickup.

The rule of thumb is rent for 3 weeks get the 4th week free.

I'm sure I cannot afford that. Dan

What's this "afford" stuff?is it for you or a customer?If they can't afford efficiency and safety, they don't need a fancy deck like this do they?

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

I wa wondering the same thing.. seems he's doing an hourly or T&M job and hasn't done much cost estimating forecasting but somehow already has the job.

Scaffold, scissors lift (best idea so far) crane for init load (good idea), are all part of the job costs.

But thinking of it now, with a scissor lift he could elimiate the crane and use the lift for everything and then not have to wrroy about spot loads where the materials are stacked being excessive. So the way I see it, the scissor lift costs eliminates the crane costs.

ever seen a roof go pop when overloaded? <G>http://www.tvwsolar.com

I went down to the lobby

To make a small call out.

A pretty dancing girl was there,

And she began to shout,

"Go on back to see the gypsy.

He can move you from the rear,

Drive you from your fear,

Bring you through the mirror.

He did it in Las Vegas,

And he can do it here."

yes

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

and maybe the special police permit.We can't see what he can on the ground but I look at that back shot of the alley and see the nose of a truck poking out from between buildings. I park a scissors lift there, the delivery truck can park to it and materials go up from there. Crew access is off the same without worry of going thru the building or up super long ladders

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

and thinking a bit more, the lift provides a 2nd means of egress if an emergency were to arise.

I like the scissors lift best.

Piffin

Put in those terms, no. Nothing has been signed yet. I have already asked them to pick up the cost of the permit above my price to build the deck. Now I am thinking, I should also ask them to pick up the cost of whatever safety measures I take to make the job site safe. I can sell it to them by saying that they wouldn't want me to cut corners on the safety of the site to save money...so can't they pay for my scaffold, my scissors lift, my barricades on the unprotected side of the building.

At this moment I can easily walk away from the job if it looks like the whole thing is a pain in butt...and it may turn out that I do that if I am not convinced the whole height thing and rubber roof thing are just not worth it and turn my sites on the next terra firma project.

Dan

>I have already asked them to pick up the cost of the permit <

You ought to be looking at this a bit differently. All of these costs need to be their costs that should've been included in the price you presented to them. If they pay for the addl access and there becomes an issue with it's reliabilty who solves the problem and at what costs? If you included in your price (with appropriate markup) you have the control to do what you need to solve the issue.

>the whole thing is a pain in butt...<

that's a multiplier you add into the cost you present to the owners. Bigger the PITA it is, the more you are owed.

This is becoming one of the more interesting threads as of late.

A couple things come to mind With this job.

1.You should have included the cost of a lift and any other cost of getting man and materials up to the roof.Plus mark up

2.I would also make sure my insurance would cover this job both liability and workers comp.

3. Why are you putting the permits in the customers name?

4.And above else the safety and effincey of you and your crew should come first.

Edited 3/14/2009 7:49 pm ET by mgard38

I take it you wanted that to go to the OP who's figuring this job?

Yes I did sorry about that.

I am changing my approach to this job. I was initially given the job at 43.5 K but I am going to go back to the client and ask to put a ceiling on the job at 50k. This will allow my the extra room I need to pay for what I know I need immediately (a scaffold, a permit, perhaps a second delivery of lumber) and it allows me money to make a repair to the roof if I have to in the course of doing the job, or if something happens over the next year.

As is it stands right now, I have signed nothing and have been given no money, but I need to build something into the contract that will allow me to do the job well, safely and still a make a small profit.

Dan

What happens if your "not to exceed" number falls short?

Sounds like the numbers are a little light.

I certainly hope that an engineer stamped someone's drawings approving the new load bearing points used to distribute the additional static and live loads... otherwise your $50k number is gonna be way short.

Has the roofer that is warrantying that existing roof approved your methods of placing additional stuff up there? I hope you have checked on that. Around here, some want those thick Firestone pads glued down and others want a treated 4 x 4 wrapped on the bottom with roofing material.

If the owners are past warranty coverage, who's buying the roof if there is a problem?

If you use the wrong stuff you *will* be buying another roof when the company holding the warranty walks. That will cost a whole lot more than a scissors lift.

You will get a hole somewhere unless everyone is real careful up there. I hope the people you work with are man enough to tell you when damage is done... plenty won't so don't take the comment personally. Masonite/hardboard works real well and it is cheap+light. Lay it down and tape the seams. Do it yourself if you need to ensure that the roof protection is done right. Toss it when done.

Edited 3/15/2009 9:30 am ET by danski0224

Hi Danski:

That is a good idea to check up on the roofer if I can find him, but I am more likely to simply reroof the entire under deck area with a heavier material, then go with pads under all 2x12x12 wood feet.

Tell me more about the Firestone pads if you can.

50k is still not 60k or 70k but there are others competing for the job as hungry as me. Upper ceiling? Probably not high enough, but it is what it is: work.

I would like to go with a masonite base and tape it like I do with interior jobs. "Toss when done" I assume means it is a paper product and will most likely be rather warps with the job is done?

I am also contemplating a on site guard rail like shown in the link, but without the manufactured boot. I will send a sketch in the next reply.

http://safetyboot.com/

Dan

Don't know anything specific about the pads other than the roofers have them, and they make nice truck floormats :)

They are about 30" square and about 3/8" thick... usually glued down as a path on a roof around equipment that needs to be serviced. Someone that installs rubber roofs in your area should be able to supply them.

"Toss when done" means the masonite isn't worth salvaging and restocking for the next job if you are using it outdoors.

How many roofs are on that building you are working on? Pretty common to see more than 2 around here. Plenty of weight... before the deck is added.

I am pretty sure you will need some type of guardrail or "controlled access zone" (CAZ) to comply with regulations. The CAZ can be something as simple as one of those lines with plastic flags with supports as required. The flag line is common here for roofers, and they have a safety monitor to watch the perimeter. If you are working 10' or closer to the edge, you have to be tied off.

Edited 3/15/2009 11:48 pm ET by danski0224

You should be able to find a clamp on guard rail system at a large rental center. maybe the place you are talking to about scaffolding can head you in the right direction, if they don't have it themself.

The post will clamp over that short curb at the edge and then you slide 2x4 in the pockets on the post, securing them with duplex nails or screws through prepunched holes in the steel. They are OSHA approved edge guards. Go up and come down easily. And, likely won't break the budget cost wise.

I take it that this is a big job for you. Which means if you don't nail down your coss/estimates prior to offering the owner a price this could be your biggest loss.

And don't start thinking these additional costs will drive the customer away from the job, because anyone else bidding on it will have the same access issues.

Don't be in a rush to give them a number. OK, so you've already given them a number. Don't tell them anything more until you have real numbers on your sheet.

and please don't think anyone is picking on you personally. This is all constructive criticism meant to keep you whole and safe both physically and financially.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Well said and thanks for adding that on there.

If we're here posting we're trying to help.

Exactly.

also all things I have to remind myself of from time to time.

Jeff Buck Construction

Artistry In Carpentry

Pittsburgh Pa

You seem to have something figured out for tie-downs.My biggest other concern is those smallish 12"x12" pads for support. If the framing in that roof deck is 16" OC, there could be places the pads are between framing and only supported by sheathing. This could make for sags and stress on the EPDM roofing there.I would use full length 2/12s oriented where yo have the stubs in line with drainage to spread the loads over greater area.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

" I have already asked them to pick up the cost of the permit above my price to build the deck. "

Wow!

next thing you'll be asking they "pick up the cost" of your labor ...

then your materials!

what's next with con artists like U?

ain't ya at least gonna supply nails?

Jeff

Buck Construction

Artistry In Carpentry

Pittsburgh Pa

Will your access be thru the building or will you need a ladder from the back to get up to work each day ?

Did you look into renting a platform hoist - electric powered unit that will hoist 400 pounds per trip up? It runs on it's own special ladder and would be most efficient for the bulk of the extra materials and supplies you'll need.

We do have access via the back steps but there really isn't room for taking lumber. I am leaning towards overbuying all my supplies. That way I'm only taking stuff down when the job is done, not up

I have also found a lumber yard with its own boom trucks. I'm thinking the best approach might be to cut a deal for a drop off at the beginning of the job and pick up at the end. That way I'm only bringing small things to the job sight while during construction.

Dan

Don't know about your area, but the rental stores are slow enough that they're dealing here. Their yards are packed with equipment.http://www.quittintime.com/ View Image

I wouldn't take anyones word regarding pricing on lifts until you check it out yourself. Using Frenchy's numbers, you are at 2 weeks of a scissors lift with 3 hours of crane + police detail/permits. Buy one more week then try to get the 4th thrown in.

Costs for crane lifts, permits, manlifts, scaffolding... etc need to be paid by the customer, not taken off of your profits. If you can't get the job with all that stuff added in, the tell the customer to get the materials up there.

Do not forget the hours you will lose by saving money with the scaffolding. I bet you will lose at least one hour per day per man. You will lose a whole day shagging material up and down. You will lose time over ordering stuff to save on a crane pick then trip over the piles trying to build something.

That scaffolding will cost you far more than it will save.

You can move *a lot* of stuff with a scissors lift. Up and down is easy- just push a button.

Your scissors lift is a great idea, and I know out here the suppliers are definitely cutting deals. Mike

Small wheel turn by the fire and rod, big wheel turn by the grace of god.

>>Operators may need to wear a safety harness and tie off when passing materials from lift to roof. You would be wise to have the receiver on the roof harnessed up and tied off.

Operators have to be harnessed and tied off at all times. Anyone working within 6' of the edge of the roof must also be harnessed and tied off. That curb at the edge doesn't meet the minimum height requierment for a parapet wall. I didn't see anything in the limited view of the roof that looked like it could serve as an anchor point. I can't recall how much weight the anchor points must be able to hold per employee attached to it, but it is high (3000+ lbs, maybe as high as 5000 lbs.)

There are railing systems that can be attached to the curbs and eleiminate the need for guys working within the 6' of the edge being tethered. Without the railing system he will run the risk of someone noy wearing the fall arrest gear, wearing it but not hooking up, a big OSHA fine for violations, or in the worst case someone falling.

Since he has to get a permit for the crane and police traffic support, you can bet the local OSHA enforcement will see that as a red flag. Happens here everytime we have to a crane setup on the street.

Handydan, you mentioned using a thicker roofing mat'l under the 2X12X12 pads (I assume concrete pavers?). You didn't specify what type of mat'l, however. Note that EPDM and modified bitumen roofs cannot be mixed or touching each other - they will eat each other chemically. From the photo I can't tell if it is EPDM or torch applied. The seams lead me to think torch applied, but the seams are spaced apart different from what I would expect for torch applied. Regardless, just make sure that you use 'like' materials for chemical compatibility. Also, if it is torch applied roofing, make sure you protect from UV the small parts of the roof that is not shaded by the deck when complete.

Thanks Natgas

Piffin warned me already about mixing different materials. My thought was to simply use more of the same material under each pad. Before that, however, I would like to cover the entire area under the roof with a secondary layer. I will be talking to my roofer about this today.

Talk to me more about the effects of UV on un shaded parts..not sure what you mean

Dan

torch down modbit needs to be recoated every five years to protect it from UV.I have no doubt from the photos I've seen that you have EPDM.to check for yourself, the EPDM looks and feels just like innertube rubber. You are probably old enough to remember when we used to use those things to keep air in the tires, LOLI'm sure I saw places in that roof with wrinkles not fully adhered where you could pinch a bit of it between your thumb and finger even

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Hey Piffin

I'm not taking the job.

After breaking down the time it would take to protect the roof, protect my team, get stuff up and get it down, half of my estimate would be gone even before construction began.

Not sure who could do it for 43.5K but it ain't me. More like 56 to 60K when it's all done.

Many thanks to all contributers. I am moving on to the next deck which is a mere triple decker on terra firma.

(Never did like heights)

thanks guys

Dan

It's been a good exercise to work thru and we've all learned from participating in.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Better to find out now rather than later :)

You know? I wouldn't give up this now if I were you. Go forward with finishing the bid, be sure there's enough money and margin in it for you and then add a little and then present it to the owners. Who cares if it's not a number you forecasted early on? It's more of a realistic number. What have you got to lose?

Well, I guess you have made up your mind, but just in case you run into it again:"Talk to me more about the effects of UV on un shaded parts..not sure what you mean"My understanding is that EPDM is UV resistant, but I don't actually install it, so I am only 90% sure of that. Modified bitumen is not by itself. That is, mod bit that goes on without a granular surface will quickly deteriorate (about 10-15 yrs around here). Most mod bit now comes with a granular surface just like your standard roofing shingle. The granules provide the UV resistance. Note that mod bit can be torch applied or adhesive applied - it is the same technology, just different technique to install. I used to do torch down, but only do adhesive applied for the last 8 yrs or so (insurance and fire safety reasons). The adhesive applied is every bit as good as torch applied.Good luck. You will come up to decks on flat roofing again.