During the past few days, I’ve posted photos of a bathroom project and a couple porches I’ve worked on during my ongoing restoration/renovation of a c.1838 Greek Revival house in Western New York State.

The feedback was inspiring, so I’m posting photos of a few more projects at the house.

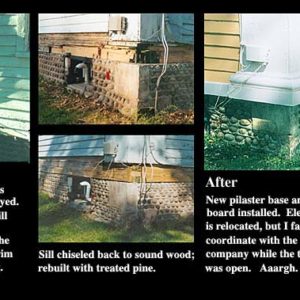

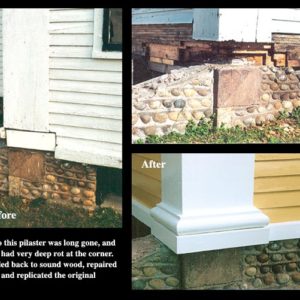

First is some examples of sill repair. Beech is a dense, hard wood, but not very high on the decay-resistant scale. There was significant rot at every corner of the sill (hand-hewn 8″ x 8″, mortised and pegged at corners and intersections). I chiseled back to sound material and repaired with treated lumber, and PL Premium adhesive.

The house is trimmed with very wide pilasters at three corners, and the column bases were all either missing entirely, or decayed beyond repair. Replicating the bases was part of this project.

Allen

Replies

This next project was lengthy and somewhat frustrating.

I removed an offensive and inappropriate exterior chimney that had been built when a central furnace was installed in the 1930s (photo #1). My plan was to direct-vent the newer, efficient furnace out the foundation.

Unfortunately, the only acceptable location, aesthetically, was not acceptable practically, according to the heating contractor I hired.

So I was forced to run a double-walled stainless steel flue straight up through the house and out the roof. This was ugly on the outside, and inside it chopped through a small bedroom. I framed around it and created a closet (photo #2). For the closet door and trim I matched the upstairs woodwork detailing, except the door is actually bi-fold because of space limitations.

I roofed the house with cedar this summer, and as part of that project I constructed a chimney in the location of the original "hanging" chimney (photo #3). The original chimney was constructed from the floor joists of the attic, up through the roof peak.

The new chimney is actually framed in wood, with a half-inch thick brick veneer. I sawed some antique brick, and also incorporated a commercially available "thin brick" product. The flue is now routed up through the new chimney.

Allen

Edited 12/15/2005 4:10 am ET by WNYguy

This next project involves my barn, which dates from the same period as the house.A large portion of the foundation collapsed at the northwest corner (photo #1). I dug down below the frostline and poured a reinforced concrete footer, then proceeded to rebuild.I used lime-and-sand mortar, except at and below grade, where I added some portland cement (photo #2).The sand I used was from a nearby commercial gravel yard, but it didn't exactly match the original foundation. So I left the mortar recessed between the stones (photo #3) until I could find a better match.I pointed up with mortar made from matching sand (color and coarseness identical to that in the original mortar) dug from a site a mile down the road. While the mortar is still soft, a light water spray exposes the sand and replicates 160 years of weathering, blending the new work with the old mortar (photo #3). The last step is a diluted acid wash and rinse after the mortar has set.The final result is photo #4.Allen

Edited 12/15/2005 4:14 am ET by WNYguy

This last project is the west-facing side of the same wing that got the new porch (see "A new porch" thread).This side of the wing had been significantly altered by the previous owners. They covered over an original door opening, and installed two mis-matched and inappropriately-scaled windows (lower right, photo #1).Additionally, there was a significant bow in the bottom third of the wall. The house is stacked-plank construction, and like a deck of cards, there can be problems with stability, it seems. The sill had also shifted, so the problem may have started there.I removed the bowed area, repaired the sill, and framed a sort of half-wall (photo #2) to support the upper section of stacked-plank.I built and installed 9-over-6 windows and a two-panel door that replicates the style of the house's other doors. There was no evidence of a transom light, but I added that for additional interior light. All the glass panes are salvaged 19th-century cylinder glass. (photo #1, top). The other three windows visible in the photo were originally 9-over-6, and will be again as soon as I make the sash.Well, that's it for now. Thanks for taking a look!Allen

allen, that place was pretty much a sack of crap before. Can you tell us what compelled you to undertake this project? How bad was the interior? Was the purchase price so good you are able to sink the dollars necessary into it? In some locations a plot like that commands a higher price because of that location, location thing. Just a little more background please, your work is very good.A great place for Information, Comraderie, and a sucker punch.

Remodeling Contractor just outside the Glass City.

Quittin' Time

Calvin: I'm passionate about Federal and Greek Revival architecture. After months of searching within a six-county area, I was smitten by this place because:Largely original -- Original footprint, no vinyl siding, many original windows, most of the interior details intact.

Affordable -- $85,000

Land -- 30 acres

Barn suitable for woodworking shop.The downside is the 1-hour commute to work, and no property value appreciation here. I recently had an appraisal for an equity loan, and they figured $65,000 market value. But that was during the "in progress" phases of several projects.In short, this is a labor of love, not profit.Allen

Have the Kodak layoffs effected your market that far out?

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Kodak layoffs are part of the whole depressing picture here. I work in downtown Buffalo, an hour from from home. Only about 45 minutes to downtown Rochester.

As long as I stay employed, the bad economy is fine with me. I have no plans to sell, and the surrounding farmland is more likely to stay that way when most young folks are leaving the area.

Wyoming County was my preferred location during my latest house search, but I couldn't find anything that met my specs. Ended up in Orleans County. Kinda flat and boring, but less snow up here.

Allen

Ours was Greek style too.I loved that farm land - lots of grapes, right? Ours was in dairy and potatoe country.

I still have two brothers in the Hamburg area, and older relatives in Kenmore/Tonawanda. There is a road named after our family ancestor in Lockport. He hit gold in CA in the 1849 rush and then bought a lot of commercial property downtown Lockport.

Then lost it all in the 1929 crash, restoring the family to its humble origins.

great Great Gramps had a cabin on Lake Honeyoye, where he lived trapping, fishing and hunting until he fell thru the ice while fishing in his 87th year. He didn't drown. The cold stopped his heart quick. No finer way to finish, eh? Doing what you love in a place others only dream of.;)

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Piffin: No vineyards near me, though there's a few in Niagara County to the west. I grew up near Canandaigua and the Finger Lakes wine country ... down there, they've got the hills and good drainage that grapes like. Up here, apples, cabbage, soy, green beans and corn seem to be the major crops. A few dairy farms, too, but lots of orchards.

In any case, it's all a far cry from an island off the coast of Maine! Bet they mostly grow fish and crustaceans up there, eh?

Allen

along with apples, taters, and pine trees

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

>I work in downtown Buffalo, an hour from from home. Only about 45 minutes to downtown Rochester.

That sounds near where my wife grew up, and where her mom and sister still live. I can't remember the town right now, but it was very close to Letchworth State Park. Next time out there I'll have to keep my eyes peeled for your GR. From what I've seen in the area it must surely standout. You set a high bar for DIYers with old houses like me.

eric

Eric, sounds like your in-laws are in the Geneseo-Mt. Morris-Nunda area. Lots of beautiful old homes down there, but I'm north, closer to Lake Ontario. Near the Erie Canal.

WNY guy,

I'm in Henrietta, small worldWhat does this situation in my life ask of me?

Trimcarp:

How's business in this area? Are you mostly involved with new-builds? I have a great deal of respect for folks who make a living doing this stuff.

My current five-year-plan plan is to push my skills to the level of furniture-making, then build American Empire reproductions in a semi-retirement mode.

I grew up in the Victor-Canandaigua area; spent four years at RIT in Henrietta, though.

-Allen

I work for my brother, and things are fairly busy. We do new-builds only and like it except for the noise and dust. We do most of our work either on Lake Ontario, Victor, and Canandaigua (all East side).What does this situation in my life ask of me?

Wow!

I'm humbled.

Art is a personal issue and, to me, you are an ARTIST.

You should begin invoicing your neighbors for viewing such a fine canvas.

An Aside: Guessing the color siding color... SW Solaria (#6688)?Troy Sprout

Square, Level & Plumb Renovations

Troy, thanks for the comments. You nailed the brand of paint, but the color was something Sherwin Williams calls "Anjou Pear" #6381, oil. I thought it was reasonably close to the color of yellow ochre mixed with a little lead white.Regarding the neighbors' view, I actually had a nightmare one night in which after the house was completely done -- all antique windows, rolling-slat shutters, wood-shingle roof -- ugly condos were built across the street. "Farm View" they called it, and all the people moving in said they bought because it was such a lovely view!Allen

So, when are you putting this all together into a book? This is great stuff....that's not a mistake, it's rustic

Jeff, THIS is the book!Allen

Well done!I am curious what the structural detail is above windows on that north wing. They seem high, penet5rating the frieze board and eliminating space for a header under normal methods. I think I know what there is there - a 6x6 top plate?

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Piffin, I was hoping to get your attention with this thread ... especially as your roots, I think, are here in Western New York.A while back I posted a couple photos on that new window construction:

http://forums.taunton.com/n/mb/message.asp?webtag=tp-breaktime&msg=53734.48Regarding the top plate, yes, you are correct. Hand-hewn top plate sits on top of the stacked plank. Your size estimate is very close; I don't recall the exact dimensions. The sill that sits directly on the foundation is 7.5-inches tall and 9 inches wide. There are no vertical corner posts; the stacked planks simply intertwine like Lincoln logs.Have you run across many stacked-plank houses in your travels?Allen

There are no vertical corner posts; the stacked planks simply intertwine like Lincoln logs.

Holy cow, that answers a lot of questions.

Quick viewing of your sill photos and I thought you had the siding cut back showing the plaster lathe.

How high do the stacked planks continue?

'Nemo me impune lacesset'No one will provoke me with impunity

Edited 12/15/2005 1:52 pm ET by razzman

Razzman, the stacked planks go from the sill to the top plate. Interior walls are constructed this way, too. Makes wiring a challenge!Allen

Interior walls are constructed this way, too.

Not sure of the picture here, could you elaborate? You're scaring me thinking someone stacked 2x4s on the interior.

be o' back when lumber was cheap and plentiful.

'Nemo me impune lacesset'No one will provoke me with impunity

Razzman, I'll have to post a couple stacked-plank photos when I get back to the office. The planks are about one-inch thick by about 4 inches wide. They're laid flat and stacked, one atop the next, nailed together.The clapboards are nailed directly to the exterior, and the plaster is applied directly onto the interior. It uses a whole lot of lumber, but it saves splitting and attaching lath. And, I imagine, it took less skill than timberframing. There's a thesis on file at Cornell University on the topic. Next time I'm in Ithaca, I'm gonna make a point to look it up. I understand the technique had a relatively short span of popularity during the mid-19th century. But it's not as uncommon as you might think.Allen

Here's a link to an old thread back before your arrival here you might enjoy. I spent some time there basically just cleaning it up, put in a couple baths and went on down the road. A dentist ended up renting the place.

http://forums.taunton.com/tp-breaktime/messages?msg=55008.1

'Nemo me impune lacesset'No one will provoke me with impunity

Razzman:

Regarding that Greek Revival house you worked on recently in Ohio ...

Did you ever post photos of the finished project? What was done with the exterior?

Did you, perhaps, save any pieces of the old wallpaper that was removed? Or maybe take photos? An associate of mine is in the midst of documenting wallpaper designs, 1790-1850, and is always anxious to have more examples.

There was a lot of potential with that house. That hallway and staircase is beautiful.

BTW, in my ever-growing home reference library I have a stack of CDs I've burned with images of Ohio Greek Revival homes (photos and drawings) from the Historic American Building Survey. Many of the photos are from the 1930s, when the survey was started as sort of a "make work" program for unemployed architects. Generally, the oldest buildings in an area were targets for the survey, so there's a lot of Greek Revival examples from Ohio. Whereas in the Hudson Valley, they were more likely to document 17th-century Dutch homes, for example.

There are beautiful high-resolution photos and measured drawings for many of the buildings. A tremendous resource for historic restoration, sympathetic additions/alterations, or new design.

Here's the link for the Website (search tip: type in a county name followed by the postal abbreviation for the state -- "Medina County, OH" -- and search by "Match this exact phrase." Then browse the through the results).

http://memory.loc.gov/ammem/collections/habs_haer/hhquery.html

Thanks.

-Allen

Edited 12/17/2005 1:01 am ET by WNYguy

Edited 12/17/2005 1:04 am ET by WNYguy

http://forums.taunton.com/tp-breaktime/messages?msg=56985.1 has a shot of a discovered rotted beam in the house.

I did manage to find an old thread I'd posted pics of the attic. Almost gave up on the BT 'adv. search function' as I was getting lost in the archives and it was being temperamental as usual.

http://forums.taunton.com/tp-breaktime/messages?msg=57222.11

The exterior was just firmed up and painted which I managed to remove myself from for the most part. The owner tightened up the windows and added a few 'gasp' vinyl windows. lol

Amazing what limiting draft intrusion can do to the comfort and heating bill of an old house even with uninsulated walls and a pittance in the attic.

Gutters were placed to help alleviate the rotted siding and damp basement woes.

The remains of the old barn and smoke/milkhouse were untouched

The owners sole drive was repair for rental so I did little towards the idea of restoration but I did when could and tried to keep whatever was there for those that may in the future.

Actually, after the discovery of all the rot in top and bottom coupled with the removal of the maze of knob&tube wiring and plumbing woes, I was biting the bullet to get out of there and salvage some sort of enjoyable summer.

And sorry that in the rush of things I neglected to salvage any wallpaper remnants which in hindsight was strange in that I normally do that. When your heart's not in a project it changes things.

In future times I will keep you in mind if I come across an involvement in that 1790-1850 age.

BTW- Thanks for the link to that site. View Image

'Nemo me impune lacesset'No one will provoke me with impunity

That period of time would correspond to the proliferation of mills driven by water power, making the saawing relatively easy by comparison to what their fathers had done, and while they were still in a land-clearing mode, wondering what to do with the lumber. That context makes it easy to understand the profligate use of wood

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

RE: Saw mills and land-clearing. Good points! The opening of the Erie Canal a decade before, and the advent of cut nails (LOTS of nails in this house) may have been factors as well.

Allen

Razz:Found a few photos of stacked-plank cross-sections. The first is an interior wall, showing the plaster applied directly to both faces of the stacked-plank wall.The second is an exterior wall with a chunk sawn out. This is the wall that had bowed out; I think that's apparent in the cross-section area. Clapboard was nailed directly onto the exterior face, and plaster applied to the interior (no plaster here ... previous owners had gutted this room).The third photo is a cross-section detail showing an original nail.BTW, thanks for the link to that earlier thread. Great reading! Hope to spend more time with it tomorrow.Allen

I've been waiting for the photos to see exactly what is being discussed.

That is absolutely incredible, and exactly what I had envisioned.

When I started my fist job in carpentry, building a house, my then girlfriend came on the job as we were laying out plates. We did what some call Eastern framing, raising stud walls, two plates on top, sole plate fixed to deck, nail bottoms of studs to sole plate, sheath from outside. (hey, I'm getting old)

Anywho, as she watches us stack up three plates, she asks out loud if that is how we build up the walls by stacking them up!! We all got a good laugh out of it and likely hurt her feelings.

But get this; guess where her mom was born and raised?? Yup, western NY!! Genetic imprinting I think they call it!!

REALLY nice work you are doing. Thanks for sharing.

Eric[email protected]

It's Never Too Late To Become What You Might Have Been

Eric: Ha! Funny story.The stacked planks have their drawbacks, but they saved my butt one day (well, saved the house, anyway). I was stripping exterior paint (ummm... yeah, with a torch), walked away for a while, then came back to find the west parlor filled with smoke.I had ignited a sliver of claboard, and the stacked planks behind it had been smoldering for five minutes or more. If that had been an open cavity in frame construction, that fire would have quickly gotten out of control.Allen

Edited 12/16/2005 1:21 pm ET by WNYguy

I grew up in a vertical plank and beam house in WNY started in 1832 and ain't finished yet, as my Dad liked to say.

Java Center, a couple miles from where Rt 78 and 98 intersect

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

in a vertical plank and beam house in WNY started in 1832 and ain't finished yet, as my Dad liked to say.

So how old were ya back then? :)

jt8

"The cynic is one who knows the price of everything and the value of nothing." --Oscar Wilde

Edited 12/15/2005 4:48 pm by JohnT8

LOLI don't remember having a childhood, now that you mention it...

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Piffin:

Thought you might appreciate this project. Back in 1992, a buddy and I built a small stone building in the backyard of the house I owned at the time.

Coursed glacial cobbles with irregular quoins. Lime mortar. V'd horizontal mortar joints, pyramidal vertical mortar joints.

Shortly thereafter, my buddy became a full-time stone mason. The third photo is an in-progress view of a 1997 commercial job in Trumansburg, N.Y. This is a cobblestone veneer on a concrete block building. Again, lime mortar (no portland cement).

Allen

Edited 12/16/2005 1:47 am ET by WNYguy

Allan

Those pictures and your work are inspirational.

I get to work in all the 6-8-10 million dollar homes that I want, but I'd trade that in a minute to do the stuff your doing on your place.

Doug

Doug, those are very kind words. Thank you.Allen

Great stuff there nightbird. lol Man, you are one laboring animal.

Mind if I ask what you used to affix the treated pine you used in replacing the rotted corner sills? I take it it was ACQ unless you had a little stockpile of the old CCA your were working from.

I recently did a similar corner sill around the same age as your Greek Revival and was lucky enough to have had a number of 3x10 creosote railroad timbers I was able to notch in and layer.

'Nemo me impune lacesset'

No one will provoke me with impunity

Razzman, I used the old CCA lumber; haven't tried the new stuff yet. The adhesive is PL Premium. I was careful to get full coverage on every meeting surface, as I didn't want moisture collecting between boards. I used as few screws as possible to minimize water-wicking penetrations, and the screws I did use were first dipped in copper naphthenate. Still, I doubt it'll hold up as well as your creosote timbers!Allen

Gorgeous house, and great work - particularly the restoration of the windows.

Did you make them, find them, or buy them?

Thanks, Rick. Here's the current window situation (by "shop-built," I mean ones I'm making myself):Main (two-story) section: 3 original, 5 to be shop-built to replace current vinyl ones.East wing: All 5 are originalNorth wing: 1 original, 2 shop-built, 2 salvaged, 2 to be shop-built to replace current vinyl ones.Here's a link with a couple photos of the windows I've made:

http://forums.taunton.com/n/mb/message.asp?webtag=tp-breaktime&msg=53734.48Allen

Edited 12/16/2005 1:41 am ET by WNYguy

ah yes, I remember that thread, you had a different name back then!

Any thoughts of doing contract window work? You have the tools and the skills, obviously.

As a revival/federal fan, you might appreciate this house I was looking at, it has about 16 foot ceiling on the parlor level, a 20/30 living room with 2 marbles fireplaces, huge windows (with antique storm windows for each) and a gorgeous stairway.

But at 600k (this is right outside Boston) , vacant for 30 years, and without a real kitchen I can't swing it.

Rick:Vacant for 30 years?! The property looks pretty well maintained. Sounds beautiful ... but up here $600,000 would buy TEN country estates.Allen

Looks can deceive - it looks ok b/c it was so well built in the first place.

It's not awful, I could deal with the paint and plasters issues (every surface, in and out) put there's tons on rot around the soffits, including nice 1 foot by 3 foot hole - so I am not sure about water infiltrtion and the kitchen is unusable. Add a few years to re-glaze and restore the windows, while living in the house with a baby - too much right now.

For 500, maybe . . .but I am told it went for 590 -

hello again - remember that house I didn't get? well, at least I have the windows -

Anyway, I inherited from the dumpster about a dozen 6/6/ sashes, the house is an 1845 federal farmhouse, - are you done with your windows? Need any?

I would love to have these put to good use, they will be sitting in my garage until I buy my own federal -

So, someone bought that house, and proceeded to rip out all those old windows, eh?

Happily you were alert enough to save them. Are the panes early cylinder glass? What sizes are they?

I haven't made any more windows; since I started doing restoration work full time, my own projects have been at a stand-still. Very frustrating.

I'm in need of 6-over-6 sash for six windows: eight sash with 9-inch by 10-inch panes, and four sash with 9-inch by 13-inch panes.

And three 9-over-6 windows with 7-inch by 9-inch panes.

Actually, I have all the muntins milled, and blanks cut for all the rails and stiles. And enough salvaged antique glass. Just need the TIME.

Allen

I haven't had a chance to measure yet, but they are really large - and they are traditional double-hung, rope and pulley balance. The glass is wavy and beautiful, undoubtedly original - though I not sure what you mean by "cylinder glass"

I will try and measure tonight or this weekend to see exactly what they are, it is a real shame, a contractor/developer bought the place and has taken 7 months to gut and destroy it - though I am told they are keeping the huge windows on the first floor.

bought for 600k, will probably try sell for 1 million and change -

The term "cylinder glass" refers to the process by which it was made.

A very large ball of glass was blown, and by standing over a trench with the blow tube vertical (ball of glass at the bottom), the ball elongated into a large "hot dog" shape.

The ends of the hotdog were then cut off, resulting in a cylinder. The cylinder was then reheated, sliced lengthwise and rolled out into a flat sheet. This process, though later automated, was the primary method of making window glass until the advent of "float glass" in the 1960s, I think.

Crown glass preceded cylinder glass. Crown glass was made by spinning a glob of molten glass at the end of a rod. This formed a large flat disc. The disc was then cut up into rectangles for window panes. You can identify crown glass by the concentric arcs evident on the surface. In the center area of the large disc, where it attached to the rod, there's a "bull's eye." This was often used decoratively, in transom lights, for example.

Anyway, it sounds like your newly acquired sash is much larger than I need. Hold onto 'em if you've got storage space ... you'll be happy to have them when you move into your Federal house eventually.

Allen

Edited 8/10/2006 11:39 am ET by WNYguy

Thanks for the info -

I will measure them anyway and let you know, they will be going the other salvage in my garage otherwise.

Just wanted to add that drawn glass was the primary method of window glass manufacturing prior to the advent of float glass. Mouth blown "cylinder" glass was certainly also available, but as a rule drawn glass was often preferred because it was less distorted and had less bubbles and striations than did mouth blown. What we consider today to be the beauty and artistry in older glass was often considered to be a flaw at the time it was manufactured.

Drawn glass was also much easier to produce on a large scale than was mouth-blown.

Until very recently, in less developed parts of the world, drawn glass was still the primary method of large-scale glass production...it may still be in a few parts of Asia, but if so, it will soon be phased out by new float plants either currently under construction or planned.

Drawn glass is still manufactured in both North America and (especially) in Europe for restoration or decorative applications. Mouth-blown (cylinder) glass is also very much available - primarily from Germany - but it can be darned expensive.

Casting, or cast glass, is another rather common method for producing decorative glass - a method that goes back a long way in time - but it is usually used today as accent glass in artglass panels or else in glass sculpture pieces or other artistic products.

Ah, yes. I'd forgotten about that. I visited the Corning Glass Museum a few years ago, and there was an excellent display illustrating the evolution of window glass manufacturing.

Of course the goal was always to produce glass with the least amount of imperfections. The beauty of old glass, to the modern eye, I think partly lies in the knowledge that it was laboriously produced by individual people, generations ago.

The imperfections also give it a more natural and "human" feeling, as opposed to the blank, uniform sterility of modern float glass. It's similar to the difference between the perfectly-spaced "clapboards" on a vinyl sided house, and the slightly irregular spacing of clapboards on 18th or 19th century home.

From Wikipedia:

"Sheet glass (sometimes called drawn glass) was made by dipping a leader into a vat of molten glass then pulling that leader straight up while a film of glass hardened just out of the vat. This film or ribbon was pulled up continuously held by tractors on both edges while it cooled. After 12 meters or so it was cut off the vertical ribbon and tipped down to be further cut. This glass is clear but has thickness variations due to small temperature changes just out of the vat as it was hardening. These variations cause lines of slight distortions. You may still see this glass in older houses. Float glass replaced this process."

Allen