Hi Mike, I’ve read everything I could on sizing a header (about 6 hours yesterday) in hopes to figure out how to do my own. I’m an owner-builder, doing my first house. Framing the garage right now before moving on to the house. I have casement windows, in pairs. The rough opening for each casement is 29.5″, and there will be a 2×4 stud separating the pair, with the nailing flanges overlapping onto that single center stud (I ok’d this with the manuf).

First, since I’m in Central California and the climate is mild, I don’t want to do insulated headers for the garage, but will definitely do them for the house. With a rough opening of just 29.5″, I know I don’t need much of a header, but here’s the rest of the information so you can picture it: garage is 19’8″ wide and 32′ long. There is a gable roof, pitched at 8:12, with the ridge beam running the 32′ length, and the garage door in the gable end. The garage studs are 16″ o.c., but the rafters are 24″ o.c. The windows in question are one pair in the rear (gable) end, and one pair on the side wall. I will have plywood sheathing everywhere, since my siding material will be shingles. I think the presence of this layer of plywood also influences the sizing of the window headers.

I’ve read about headers made of 2×4’s on the flat, one stacked on top of the other, and am wondering if this is a good solution for my openings. (How do you decide whether to put the 2×4’s on the flat or on edge?) I thought it made the most sense to run the header over both windows in the pair, which would make the length 29.5″ + 1.5″ (center stud) + 29.5″ + 3″ (ends of header beyond rough opening), which comes out to 63.5 for the cut length. But with the center stud running from header to sill plate, isn’t it true that the header span is just the 29.5″ ?

So can you advise me? My engineer has spec’d 2×12’s everywhere, and I know that’s a joke. I want to minimize down to what’s necessary and not waste resources.

Also, since windows are hung with nailing flanges, the sill under each window doesn’t need cripples at each end, does it? I would just need to have cripples for plywood seams, right?

Replies

'E' for effort - here's converted to jpeg and a little friendlier to the slow connections -

barbara....

i would think for that size opening ( 29" ) a 2x4 header woiuld be fine

i'd use two 2x4's on edge with a 3/8 plywood spacer

View Image

generally speaking.. yes. you can eliminate cripples if there is no plywood joint falling out at that location... nice garage !

I'm in Central California

My engineer has spec'd 2x12's everywhere, and I know that's a joke.

your BI will make you prove that the 2 x 12 are a joke if that is what is speck out for.

You are not going to get very far in that state (ca) doing any thing but what is called for in the plans. The (BI) building inspector will make you tear it out and build to the approved plans. Unless you have new plans and specks that have been signed off by a engineer saying that you can do it a different way then what is in the plans. Most states are not as much a pain in the rear, as CA is when it comes to building codes. Or so I have led to believe CA is.

The best way I can see is to go back your engineer and ask the engineer to prove why you need the strength of 2 - 2x12s instead of 2 2x4s

Edited 7/14/2005 2:21 am ET by fredsmart

barabara... fred is exactly correct.... your engineer may be designing to a seismic code or a wind uplift code that incorporates the header into a shear wall

in terms of span load.. the 2x4's fit the bill... but in terms of seismic & wind.. you'd best consult your engineer or Building Inspector...

sorry if i mislead you... still a nice looking garage thoughMike Smith Rhode Island : Design / Build / Repair / Restore

Barbara:

FYI, the 2x4 in the center of the 2 windows is called a stud pocket. Actually, I use two 2x4s so that the window flanges won't have to overlap. If you do that, and use a 1x4 or whatever you are going to trim the windows out as a spacer during the window install, it makes the siding phase go a little smoother too.

2x4 on the flat headers are normally used for interior non-load bearing walls.

Edited 7/14/2005 9:40 pm ET by Matt

Matt, Mike, Fred, and David,

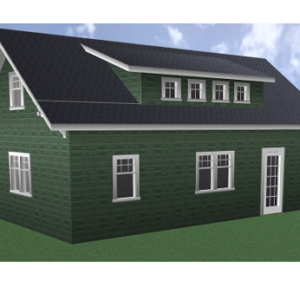

Thanks to all of you for your input. My draftsman is a go-between between me and the engineer. I met with him yesterday, and told him I really need to know what size headers are appropriate. He said "oh we just put in 2x12 everywhere because it covers most loads, and we never do calculations for individual windows". Sounded to me like they just couldn't be bothered. As for seismic, the engineer has spec'd 3/8 plywood at the four corners, wrapping 4 feet both ways around each corner. But besides that, I need to apply 3/8 plywood to the entire structure because I'm putting up shingles. Plus the inside will be sheetrocked. I think I'm just going to install 4x4 headers on the 3 garage windows and man door and see what happens. Mike, thanks for your compliments on the garage design; I used Punch software to design it, and it matches the house.

I don't think you even need a header, other than one 2x4, on gable walls as they aren't bearing any roof load. The other windows are so narrow, I don't see why 2 2x4's oriented the same way as the studs so you don't need a spacer (i.e., width running inside to outside) wouldn't be adequate. Certainly 2x12's are overkill and a waste of good material and money. I suppose you could ask the building inspector.

The windows in question are one pair in the rear (gable) end, and one pair on the side wall. I will have plywood sheathing everywhere, since my siding material will be shingles.

The window on the gable end in your picture is a single window and I assume the double window on the sidewall is the one directly underneath that window on your gable end, right?

I think I'm just going to install 4x4 headers on the 3 garage windows and man door and see what happens.

Now why would you go and do that on the main door which is not on the gable end according to your drawing? That door header has ceiling joists, rafters and part of your dormer to hold up.

Joe Carola

Edited 7/16/2005 8:03 am ET by Framer

Using way oversized headers is very common in the residential building industry, or at least here in NC it is. It annoys me because it not only waists the big boards - the expensive ones - the ones that from a "green" prospective are the most valuable, but it also reduces the number of sq ft on sidewall insulation on a house. Framers like to do it though because on 8' ceiling houses, they just slam their headers all the way up to the wall's top plate and have a nice day. Usually a 2x4 spacer goes below - that's it. Around here they always use 2x10. This has carried over into houses with > 8' ceilings too. I've found this mindset impossible to break, and some of em even want to use 2x10 for interior non load bearing headers. What's worse, as you said, it is often specified on the plans which just propagates the problem and leaves you, the builder no choice it you want to be positive that you will pass your framing inspection - ie building inspectors want the house built per the plans.

I had a house framed a few months back and header size was not specified on the plans. I used a framing crew who I have used before and who pretty much do good work. I ordered only enough 2x10 for the front porch beam - that's it. For the windows and ext doors I ordered 2x6 for the small openings and 2x8 for the larger openings to try to save lumber and build a more energy efficient house. I told them to just cut all their jacks to 81.5" and set the headers on those. The day they stood the walls up I wasn't there. When I did show up I found that they had again just slammed the headers up to the top plates and padded the window and door opening heights down with a whole slew of 2x4s to approximately the right height. BTW - that's another thing that is common with framers - they don't really exactly follow the window height specified on the plans. So anyway, the door openings and single window openings were padded down with, maybe 4 2x4s! What a colossal waste. This was, I imagine because they didn't want to mess with cutting cripple studs for above the headers. I've had similar things happen before. They did cut the interior jacks at 81.5" and used 2x6 headers on the 5' wide closet door openings like I asked them too, but on the regular doors (all non load bearing walls) they just used 1 2x4 on the flat - I asked them to use 2. They did put cripple studs above all of the interior headers - hallelujah!! The bottom line is that in the area of headers, I've found most all framers do what they feel like. Yea, I know, it shouldn't be like that, and I gotta guess that the national builders have enough control over their framers so that they do as they are told, but for a builder who's only building a handful or 2 of houses a year, we don't't have the leverage... Me, I just pick my battles and make 'em fix stuff that really effects the quality of the house like door frames that are out of plumb, openings that are the wrong size, house wrap that is not lapped properly, bad studs that weren't culled, stuff I know may not pass the framing inspection, and the like. The deal I detailed above where the waisted all the 2x4s, I choose not to say anything about - I mean it was already done so why get one's panties in a wad...

What I'm getting at here is that as a builder you have to be somewhat flexible and adaptive. I find that framers tend to be a breed unto their own, and every crew has a few things that they do their way... We can't look at it like - well I would have done it this way because as construction managers we didn't actually do the labor, nor can we always get our way. Not to worry, you just gotta look at the overall quality outcome and everybody ends up happy. You said you intend to use 4x4s for headers, but don't be surprised if something else happens and they use the 4x4s to cook their lunch on... :-) Personally, I have never seen a 4x4 header, however I am aware that out west they use solid timber for headers - we always 'laminated' 2x material with 7/16 OSB spacers.

The only way to get everything done exactly the way you want is to do it yourself, of have employees directly employed by you (no subcontractors) and be with those employees every minute... But that's not what a good manager does... Or be like Mike Smith and have guys you have trained over the years...

Here is a link to our NC state building code that gives allowable header lengths:

http://www.amlegal.com/nxt/gateway.dll/NC%20Residential%20Code/part00382/chapter00657/section%20head00661/section00673.htm?fn=main-nf.htm$f=templates$3.0

It is based on the 2002 IRC.Matt

Matt, I hope you feel better after ranting about framers. I also want you to know that you can shoulder most of the blame.

Here's why: "I had a house framed a few months back and header size was not specified on the plans."

It seems that you have enough time to complain about wrong headers, but you didn't have enough time to specify them on the window schedule and you didn't want to bother drawing section views specifying your preferences.

Personally, I'm a minimalist and I'm also very experienced in the wishy-washiness of one time homeowner-builders and part time builders. They don't have enough experience to actually know why a lot of things are done the way they are, but they are really good at knowing how it should be done, after the fact.

If you guys really knew what you were doing, you'd supply complete sets of drawings including all section views, window schedules (with the actual manufacturers windows, not some generic numbers) and a host of other data that would actually make our job easier.

In the absence of decent plans and specs, we've trained ourselves to wing it.

blue

Blue:

I figured that might draw some flack.

It was not meant as a slam on framers, but was more to say that a builder needs to give them a little leeway to do things the way they know will work, and will pass inspection. Throwing in a bunch of odd details just slow the framer down and makes the job less profitable for him. To me, 4x4 headers would be an odd detail, but I have no idea what would be common in the part of the country where the original poster lives. In the case I was talking about, they are really low margin houses and I wanted to try saving some money by sizing the headers for the openings - wrong!!!

Another thing I thought about but I didn't state as I felt the post was way too long already was that I have immense respect for framers as their job is very labor intensive, has a high incident of accident, and, to the individual worker, doesn't pay real well for what they have to do. Though not worth much now I worked on a framing crew full time for 2 years when I was 19 - 20 YO, so I still remember getting dizzy from the heat and wondering if my fingers were permenantely damaged from frost bite. This was in the days before OSB was in common use :-)

That said, let me respond to a few of your statements:

>> Here's why: "I had a house framed a few months back and header size was not specified on the plans."<< what I meant was that they were not specified by whoever drew the plans, and the plans were not engineered as other than the trusses there was nothing to engineer - I hand wrote the header board sizes and # of jacks on the plans in green ink. I always use green because it is pretty uncommon. So the header board sizes were right there and the guys used the correct material. It was just ridiculous the way they installed them. I told them to use 81.5" jacks (which they didn't), so that should have surficed. Granted, doing it my way they would have had to cut the top cripples to the correct length. If you want I'll draw a picture of what I'm talking about.

>> Personally, I'm a minimalist and I'm also very experienced in the wishy-washiness of one time homeowner-builders and part time builders. They don't have enough experience to actually know why a lot of things are done the way they are, but they are really good at knowing how it should be done, after the fact. << I understand that statement, but it has nothing to do with me, so I'm assuming it wasn't directed to me.

The thing that many subcontractors do not have is an overall view of how the different aspects of the project mesh together. For example, in another neighborhood, on a house the plans specified the 2nd floor window height at 6'8" but the framers set the window ROs at ~7'2". There was to be a 12" band board in the siding details for the gable ends. Having the windows up there would have put the top of the windows into the band board. I could have used a smaller band board, but decided to have the framers move the window ROs down (windows were not yet installed) - per plan. It did cost me whatever lumber was used to pad down the ROs. Being a nice guy, I didn't make them move the ROs for the parts of the house that did not get the band siding detail. If I remember correctly, you do siding too, so wouldn't have had this problem. That framer's reaction was - well, I set all my windows at 7'2" for 8' ceilings.

>> If you guys really knew what you were doing, you'd supply complete sets of drawings including all section views, window schedules (with the actual manufacturers windows, not some generic numbers) and a host of other data that would actually make our job easier. << Fair enough, but let me ask you this question: what level of detail would you expect to see on plans for a slab on grade 1 story 1180 sq ft box with a raised shed roof front porch and a small bay window and a 6'x6' attached shed on the back? The plans for the houses in this neighborhood are 5 pages: elevations, foundation plan, floor plan, sections, and a code compliance page. Also the engineered truss plans supplied by the truss manufacturer. The houses are vinyl sided with vinyl windows - the ROs are the same size as the window size on the plan, so I see no need for a window schedule - I gave that to them verbally. I will say the 2nd and 3rd houses they did a little better on but I told them that, going forward, I'd just order 2x10 material for exterior headers. If you want I can also tell you what parts of the job they did really good on... I plan to keep them around... Matt

Matt, I figured I might cause some flak too, but I am glad that you understand that I'm not getting personal.

I can't and wont defend a framer that would use a 2x8 header, then stack a solid pile of 2x4's on top of it instead of cutting cripples. But, I also would not endear myself to a framer that cut and installed small cripples that are easily split in the normal nailing process. Anything under 6'' tends to disintergrate with todays lumber.

One of the problems that I've encountered over the years, working on small production homes, is that the section views tend to be generated only for the benefit of getting a permit. Essentially, they are a generic version of a framed wall and for the most part, they don't even match the realitys of the house we are framing. It's not uncommon to see the wrong size overhangs, wrong sheating, and every window is specified at 6-8.

So, do we set our windows at 6-8? NEVER! And why don't we follow the plans and specs if they say 6-8? Because the elevation view shows the tops of the windows and door lined up. That's called a conflict. Almost every plan has conflicts like these.

Now, occassionally, we build for a builder that actually wants the windows set at the height of the specified window. Of course, we don't find that out till after ALL the windows are framed and set wrong. Even if we point out that there are conflicting indicators on the plans, they seem to think that we should automatically know which particular detail takes precedence; damned if we do and damned if we don't.

Myself, I'm pretty intuitive about what should take precedence. That skill comes from 30 years of deducing what the architects, builders, and homeowners actually want. For instance, if I saw a note penciling in the header materials for each window, I'd be very appreciative and use exactly that for each. If I decided that a change was needed, I'd probably discuss the particular reasons for the change before I did it with the superintendent, or be prepared to change it back to their idea on my dime.

Now onto specifics: You mentioned a job where the need for the 7-2 window height was encroaching onto a band board. My question is this: was the band board shown on the elevation views? Was the height of the band board noted or dictated on the elevation views? Was their some way for the framers to know that the height of the band board couldn't be altered?

It sounds like the height of the gable windows was critical for the elevation. Would it have been too much trouble to put handwritten note on the plans indicating that the band board was the determining height of everything?

I mention this because I don't see why you couldn't find a way to elegantly raise a band board on a gable end. The one exception might be in a Tudor styled stucco home where the grid lines are so critical in both the horizontal and vertical trim members.

Basically, I'm trying to tell you that there are a huge variety of variables that lead to the decision to complete all of the exterior details. The exterior details dictate the interior framing details. Around here, every house is a very flexible design, dictated by many different factors. My decision process regarding header heights goes something like this: I never look at the height specified on the section sheet. I go to the truss and determine the heel height. I do the math to calculate the height of the top of the fascia. I go to the lumber pile to see what they've sent out. I make a guess as to what the lumber guy has shipped for the fascia and frieze and soffit. I make a decision about these members, then do the math to determine the bottom of the frieze. This becomes my "pineline". I then position the bottom of the header in accordance to this datum point.

Oh yeah, we can't forget that the rough window header will vary up to 3'' simply due to the type and style of the window, especially related to it's flanges or brick molds.

I'm trying to make you understand that the height of the window is not cut and dried. There's a starting point (about 6-8 high) but a wide variety of factors might push it up or down, depending on a host of other issues (egress, ingress, roof flashing requirements, etc).

Of course, all of these details could easily be drawn and figured out before the framer starts. 99.99% of the builders choose not to involve themselves so heavily in the process becasue it would take them about an extra hour preparing the plans and specs. It's much easier to use the build it, criticize and let the framer change it method. The builder's choice is this: spend an hour of their own before the house is built, or make the framer spend 5 or ten hours of his after the dust settles.

Most builders choose to save their own hour at the expense of the framers ten.

I think you know where I'm coming from now. Nothing personal though. Which group do you belong to?

blue

ps I once had to raise a very heavy plate glass round top window 12'' higher above the door in a two story foyer. The superintendent "forgot" to mention that the plan was wrong and that he knew about it because the previous crew had to move their window up too. Again, it's too much trouble to change the stock plans...it would have taken five seconds before he ran them, but why spend five seconds when the framer will have to do it for free!?!

I hear you about plans lacking detail and accuracy. In my case, I'm the super, not the actual builder. My boss is the builder. Generally, I'm handed the plans, and told "here, build some of these over there". A few times when asked "are you the builder" by a causal passer by, I'll answer "No, my boss is the builder. He has been by the site 3 times. He got out of his truck once." ;-) So, although I don't get much, if any input into the plan development process, I am left alone on site to do what I please as long as I'm not pi$$ing away a bunch of $. I like that arrangement. It lets me make some decisions that I feel produce better quality homes even though they may look exactly the same as a house with no window tape, for example.

Like you say though, on the plans I get, the sectional sheet is always a joke, used only to get a building permit. On the cheap houses I was talking about with the 2x6, 2x8 header thing, the section sheet shows one section with brick veneer, a detail for a brick chimney, one showing a stick framed roof, and one showing wood decks - none of which the houses even have. I'm sharing this, not because I think you want to hear it, but rather to help educate outer readers as to what reality is. Still, window height are always clearly indicated on the elevation page(s) which are accurate. To the other extreme, when I built my personal house 6 years ago I had plans that were around 17 pages in length and showed nearly everything. These plans were produced at considerable expense to myself. In the end, I realized that I was the only one who really had a thorough look at the plan and the great plan set was more just a waste of %money. So there is a balance on plan completeness too.

Right now, on the somewhat more expensive houses I'm building I have a page of schedules for flooring, windows/doors, Interior trim, plumbing, etc. I have a great trim guy who does good work for a reasonable price. Still, each time he trims one of these houses, I lay the plans open on the kitchen counter open to the schedule page and when he starts asking me the Qs about what room gets what, I answer his Qs but also remind him to look at the plan if you want to know what room gets crown, for example.

So, if I worked for one of those very large builders I'd likely have better plans that could really be relied on, all the takeoffs would be done for me, I wouldn't have to mess with getting my own permits and things would be a little easier for everyone. On the other hand the takeoff would be figured down to 2 or 3 2x4s, and if more had to be ordered, both you and I'd have to explain why to some accountant. Also, I'd be telling you how much you are gonna make, and the little extra detail on this particular house, you are going to do for free if you want the other 25 houses I have stacked up in the queue. What fun would that be?... Personally, I'd like to work in a situation that is equatable for all involved parties. Matt

Still, window height are always clearly indicated on the elevation page(s) which are accurate

Matt, I once worked for a builder that almost always handed me plans that showed one detail on the floor plan and a conflicting detail on the elevation view. We had a clear understanding that the elevation view took precedence.

A note in red ink (most plans we work off have a fair amount of red ink). Red ink are handwritten changes that take precedence over the stock plan.

Another builder I worked for got tired of adjusting door headers at the trim stage. He solved the problem by writing in red ink all door headers to be 6'- 10 1/2"!

Problem solved.

I've also worked for custom builders who had the floor plan dimensioned down to the 1/16"! Every header was specified including the heights. It was a pleasure building the 80 some headers in that house digging everything I needed from one lift. When the header list was done, there wasn't one stick of lumber left in that lift. More surprisingly: the specified height of the window acutally fit to the cornice details! On those plans, the architect had dictated the height of the heel and like magic, everything falls into place.

My point is this: if the dumb framers can figure all this out, is it too much trouble to ask the professionals (the builders or their representative superintendents, and architects) to figure all this out and order the proper materials?

I don't let any superintendent off the hook simply because he claims he is NOT the builder. Bunk! If you are the guy superintending, the builder has delegated his building responsibilities to you. Not having total control is just a lame excuse. You have the ability to red ink every plan and make all the necessary notes to get the job done in whatever manner you desire. Usually, all that needs to be done is have a philosophical discussion regarding your goals with the framer. If you can get him to understand where your prioritys lie, before the frame starts, and provide him with enough details and specs, you'll probably get the desired result the first time.

You mentioned faulty spec sheets. My solution would be to red ink the faulty spec sheets. I'd cross out the brick. I'd cross out the 6-8 window height and red ink in the same height that is specified on the elevation view. I'd specify the 2x6 header stock or indicate that each header varies. If I was particular about how/what/where/why the cripples were located, I'd red ink a note, something like this: Note: all header stock should rest directly on the jacks and cripples used in a way to maximize insulation.

If the framers missed any of the red ink notes, I'd simply make them make it right on their dime. The same goes for not reading an elaborate 17 page set of plans. If the builder has drawn them right, then the framer should build to them.

Lastly you said in regards to working for a large builder and tight takeoffs: "On the other hand the takeoff would be figured down to 2 or 3 2x4s, and if more had to be ordered, both you and I'd have to explain why to some accountant. " I've been there, done that. I always have the answer; "I don't know. All I know is that if you want me to finish the house, I'll need yada, yada, yada." I don't make explanations for materials that are lying around in a subdivision of thieves for weeks on end. If the bean counters cant figure out where it's all going, I'm not going to try to explain it. I might suggest that they move their desks to the jobsites and watch closely for the two weeks that the job takes. It might mean a few sleepless nights, but I'm sure they would get their answers.

blue

Thanks for your insights. Some good info there. Also, it sounds like you have a pretty good handle on a few aspects of what my job entails.

Thanks,Matt

You've never seen 4x4 headers? Hmm, maybe not such a good idea then. I just thought of doing that because the old garage that was here had a 48" rough opening width and used a 4x6 header. So I just guesstimated down from there, since my R.O. is 29.5.

Your stories about framers makes me glad I'm building it myself. Just me and one friend will provide all the labor. I want to do what's correct and not overkill, use resources wisely and all that, and of course pass inspections. To that end, I spend hours and hours in Breaktime, on a myriad of topics. Plus, I have about 6 books from the library right now, all on framing. Even with all 6 books, I haven't been able to answer the header question. Thanks again for your input, Matt.

Barb:

To size your headers look at the link I gave you earlier. Also, you may need more than a pair of jacks for wider openings. The thing is I know nothing about the seismic zone you live in so I don't know how that effects things and further more, I believe we get entirely different species of lumber here on the east coast. Also, if solid timber stock is available where you live to use as headers, then go ahead, use it. Around here we don't get "timber" style wood that is meant for framing - the only timbers are PT and rough, full sized stuff. I wouldn't size your headers based on an old building though. Codes change on a regular basis. Really though, if you are going to act as a builder, you need to get a copy of what ever building code you all use in CA and reference that. The code books I have used for the areas I have built in seem a bit daunting at first but once you break it down into sections, subtract out the stuff that is irrelevant to what you are doing, then it's not so hard to get around in the book. As was said earlier, your building inspector could challenge you on using headers that are smaller than those specified by whoever engineered your plans, in which case you would need to get an engineer's letter to pass the inspection. In my area, these cost about $150 which could eat up your money saved on wise use of material in a hurry. Matt

I couldn't open your link actually. It said "you do not have access to this site". Monday morning I'm gonna take up this issue with the guy down at the building department who approved my plans. Will let you know what he says.

The table is attached in M/S Word format. There is 1 part for headers and 1 part for jacks. It is from the NC version of the IRC 2000. I think California uses the UBC. Figures that they would have to be different :-)

Matt

The Table attachment was nearly blank. Try clicking on it yourself and see if it's nearly blank for you too. Oh well.

I did go down to the building dept today and met with the guy who did my plan check, and he told me that 4x4 doug fir headers were all I needed for the 29.5" rough opening on all my windows. So Yay!! No 2x12 madness. So I guess 4x4's are done in these parts, unlike where you live.

He gave me a copy of a table he uses during plan check. I'll copy the 5 lines that relate to window and door headers:

Size Opening

2-2x4 or 4x4 Up to 4'0"

2-2x6 or 4x6 4'0" to 6'0"

2-2x8 or 4x8 6'0" to 8'0"

2-2x10 or 4x10 8'0" to 10'0"

2-2x12 or 4x12 10'0" to 12'0"

My only question now is, for the 2-2x4's, would they be on the flat or on edge????

Matt, thanks for all your help on this thread; I really appreciate it.

Barbara

Must be a compatibility prob with your computer. I have Word 2002.

2x4s go on edge. We use 7/16" OSB as a spacer.

The reason I didn't type the table is that it is all dependant on what is above the header, and what species of wood you are using. Here is a bit of the table:

Residential Code - 2002 Edition<!----><!---->

R502.5 Allowable girder spans.<!---->

The allowable spans of girders fabricated of dimension lumber shall not exceed the values set forth in Tables R502.5(1) and R502.5(2).<!---->

TABLE R502.5(1)GIRDER AND HEADER SPANS FOR INTERIOR AND EXTERIOR LOAD CONDITIONS20 psf Roof Live Load<!---->

<!---->

<!---->

Building Width (ft.)<!---->

<!----> <!---->

<!---->

<!---->

20<!---->

28<!---->

36<!---->

20<!---->

28<!---->

36<!---->

20<!---->

28<!---->

36<!---->

20<!---->

28<!---->

36<!---->

<!----> <!---->

<!---->

<!---->

Maximum Header/Girder Spans (ft-in), for Common Lumber Species1<!---->

<!----> <!---->

<!---->

<!---->

Douglas-Fir-Larch<!---->

Hem-Fir<!---->

Southern Pine<!---->

Spruce-Pine-Fir<!---->

<!----> <!---->

Headers Supporting<!---->

Size<!---->

ft-in<!---->

ft-in<!---->

ft-in<!---->

ft-in<!---->

ft-in<!---->

ft-in<!---->

ft-in<!---->

ft-in<!---->

ft-in<!---->

ft-in<!---->

ft-in<!---->

ft-in<!---->

<!----> <!---->

Roof and Ceiling<!---->

2-2x4<!---->

3-9<!---->

3-5<!---->

3-1<!---->

3-6<!---->

3-2<!---->

2-11<!---->

3-9<!---->

3-5<!---->

3-2<!---->

3-7<!---->

3-3<!---->

3-0<!---->

<!---->

2-2x6<!---->

5-10<!---->

5-0<!---->

4-6<!---->

5-6<!---->

4-11<!---->

4-5<!---->

5-11<!---->

5-3<!---->

4-8<!---->

5-8<!---->

5-0<!---->

4-5<!---->

<!---->

2-2x8<!---->

7-4<!---->

6-5<!---->

5-8<!---->

7-2<!---->

6-2<!---->

5-6<!---->

7-8<!---->

6-8<!---->

5-11<!---->

7-3<!---->

6-3<!---->

5-7<!---->

<!---->

2-2x10<!---->

9-0<!---->

7-9<!---->

7-0<!---->

8-9<!---->

7-7<!---->

6-9<!---->

9-4<!---->

8-1<!---->

7-3<!---->

8-10<!---->

7-8<!---->

6-10<!---->

<!---->

2-2x12<!---->

10-5<!---->

9-0<!---->

8-1<!---->

10-2<!---->

8-9<!---->

7-10<!---->

10-10<!---->

9-5<!---->

8-5<!---->

10-3<!---->

8-11<!---->

8-0<!---->

Matt

Edited 7/18/2005 10:08 pm ET by Matt

Hey thanks Matt for getting that table to appear; I find the table really interesting and helpful. My building is just 20 ft wide, so I can look up the information on that width. Thanks verrrrry much.

Barbara

I ran across this pic last night while looking for something else. So much for efficient use of materials :-(

Matt

3/8 ply for sheathing? You need more than that if you're planning to shingle it, 5/8 would be my choice.

Joe H

Edit, what kind of seismic & wind zone are you in? That 4' of 3/8 ply at the corners is pretty cheesy. I can't remember seeing anything like that for a loooooooooong time. Did this pass through the local building permit process?

Edited 7/16/2005 2:04 pm ET by JoeH

I'm in Sacramento CA, which on the map is Zone 3. Since you're worried about 3/8 plywood for shearwall, I'll double check that with the building dept. It was engineered that way, and they passed it as far as the plan check and permit, so...

And as far as 3/8 not being enough for applying shingles, I'll look into that too. Will check with Hardie installation guide. I should have thought of that before. Fibercement shingles are pretty heavy compared to cedar.

Edited 7/18/2005 1:37 am ET by BarbaraD