Anybody every made/used the “Simple Homemade Scaffolding” shown on the pages of our esteemed host here:

https://www.finehomebuilding.com/how-to/articles/simple-homemade-scaffolding.aspx?ac=fp

I’m thinking of making a set, but using 12′ instead of 8′ 2x4s; my idea is to still fasten them at the 8′ point, but allow the crossed tops to remain for use in connecting hand rails between the two sets of legs.

http://i27.photobucket.com/albums/c197/Peregrinor/ww/2010_housework/scaffolding02w1.jpg

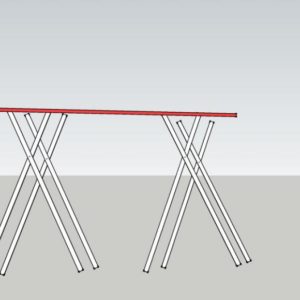

I haven’t added the “rungs” in this diagram (still struggling with Sketchup), but the red portion would represent the “handrail” I’m thinking of.

Is this a stupid idea?

Replies

The setup I made was quite a bit different: flat frames with 2x6 verticals and 2x4 horizontals, put together in a sort of ladder, with plywood gussets. I made 8-footers with two crosspieces at 2' and 6', and 4-footers (for added height) with a single crosspiece.

To set up the scaffold I'd set two frames at 90 degrees to each other and 45 degrees to the wall. Use short pieces of 4x4 through-bolted to hold the two frames together (and to hold the 4-foot extensions on top), and another piece at the bottom for an outert leg, since I was always working on a slope. Set up pairs of frames about every eight feet and run planks across between them. Tacked a handrail to the tops of the verticals.

Stability was excellent (I don't like shaky scaffold). The setup could easily have been put together with two 8-foot sections for taller buildings, but I didn't need the height.

Had the scaffold up around the house for about 9 months (through the winter) while we resided.

Sounds interesting, tho a bit hard to imagine. Got any photos?

"A picture is worth a thousand words"

No, this was 15-20 years ago, mostly before digital. Might have a couple of snapshots somewhere, but it would be a chore to dig them up.

Basically, the frames were H-shapes stacked one on another. Putting two together at an angle made for a very rigid, self-standing frame. A bit of a pain to put up, but since they tended to stay up for 2-3 months in any one location that wasn't a big deal.

Thanks, Dan. I think I get the general idea.

Mike Smith had posted pics of the setup that he uses

very similar if not the same as Guertin's.

Great idea.

Too bad the pictures that used to be here, formerly semi easily searched out...................

are probably done gone.

Look up smitty and ask some questions.

I needed something similar and found an inexpensive setup for sale at Lowe's. Home Depot has the same product. It is a tubular scaffolding frame with a steel platform. It is 4' wide and about 4' high. It is quite sturdy. I bought two of them which gives me 8' of width, or longer if I need it, by spanning the two with long boards. They have lockable wheels which makes them easy to move/reposition. When you no longer need them, they fold down into a very compact package for storage.

When I first got them home, I thought they might be crap. They ended up being one of the most important "tools" for my last project.

I thought this might help.

Thanks, Mike. I don't know where I'd begin to look for them here in Japan, tho. I just brought in a container of Hardieplank and flooring, and if I'd thought more about this stuff before, I'd probably have bought a set of pump jacks to use.

In Japan don't they use that bamboo scaffolding all the time?

I don't think I've ever seen bamboo scaffolding in Japan. Thirty years ago I used to see wired-together scaffolding made from lots of small logs about 2-4" thick (you still see it on occasion), but now almost everything is metal pipe in the Tokyo area.

Here's a photo of some of the wooden scaffolding logs:

http://craft-f.way-nifty.com/photos/uncategorized/2007/10/08/cimg2049.jpg

and an example of how they're used:

http://userdisk.webry.biglobe.ne.jp/003/326/60/N000/000/001/124769159281616216891.jpg

OK, I think I'd seen pictures of that sort of scaffold and assumed it was bamboo.

I remember seeing this stuff, too and an architect friend of mine talked about how they'd use the stuff even on high rises. Bamboo is very strong and not unlike tubular steel found in conventional scaffolding. Might be worth a google.

The article says you can make these scaffolds for less than a day's rent on commercial ones. I rented commercial ones for like $35 a month (uprights only as I had my own 'plank'). Renting scaffolding is cheap unless you don't have the rental resource.

Otherwise, your idea is great ... 'cept the 'railing' only works at the upper level ... maybe two. It's easy to put it on other levels, though. Most people don't work w/ a 'railing', though. Maybe it's OSHA req'd? Even commercial work I've seen often has no rail, although I don't look at each and study that aspect, really and I've been on some commercial scaffolding myself and don't recall it.

There is no OSHA here in Japan, so it was just my idea (and due to thefact that I ordered 12' 2x4s). I will have metal scaffolding up in in the fall for the final part of the job, but I want something to let me work up to the level of 15' or so before then, thus the idea of using this stuff. I guess I'll try building it and see what happens.

I always thought OSHA was Japanese ... just kidding ... bad joke.

Ultimately you'll undoubtedly learn from your experience, so whatever works. I shopped on line for scaffolding and it was a little expensive ... I didn't mind as I could always resell it ... but then went to the rental yard and for the paltry rental fee, I couldn't pass up using it for 2-3 months while I finished my siding and then did my drywall inside.

Whatever you do, though ... try to enjoy it thoroughly!!

I've heard that in some areas of the country scaffolding is real cheap to rent, but it's virtually unavailable for rental in other parts of the country. Has partly to do with liability, I think.

Last time I painted the house I rented some scaffolding -- I forget what it cost exactly, but it was reasonable for a week, but would have been painful for 3 months.

This is the first time I've ever priced scaffolding here in Japan, but everybody says it's pretty expensive; I'm getting an estimate for two months, since that seems to be a rough norm for short-term usage. Anyway, I gather that the biggest expense is the labor for setup and take down, but I haven't gotten the estimate back yet, so I'll be "interested" to see what they say.

As for the OSHA business, there is no culture of working from ladders and ladder jacks here; nobody here will work on a building without scaffolding, and that creates the need for an entire new industry of scaffolders. So I have the cynical theory that it's in part a "make work" scheme by the zenekons (general contractor companies) to keep a class of people employed and more overall money flowing into the construction industry. Maybe it helps keep the crime rate lower.

I suppose it can vary. The liability thing sounds like BS as you could say that about any tool you rent. Particularly power tools and the like where there is mechanisms involved. Interesting that my bargain in my neck of the woods doesn't hold up elsewhere. I did minimize my time of use by installing as much of the siding as possible before I needed to go up. That included using my Little Giant and scaffold plank up to like 6-8 ft I think it was.

Here's what I set up when I was working on my previous wreck.

Couldn't resist posting this.

Disclaimer: Please don't try this unless you're crazy...lol

PS...OSHA would've had a field day with me...lol

Crazy color

True. You must be completely bonkers to have included the orange ladder. It simply doesn't mix well with the others.

you can have that orange ladder if you want..really. Things so heavy you need two people to carry it without getting a hernia plus I never have the need to go up as high as it does at least I haven't in a col a decades.

Prolly should just break it down into two and use em' to shove my scaffolds through...heyyyyyy..why didn't I think of that b/4?

Thanks sap : ))

So, if you start a marble rolling down that ladder at top right . . .

What kind of house are you building in Tokyo? I hope things are better up there, things are pretty slow here in Oita. I've taken to cabinetmaking because 2x4 houses aren't selling right now...

We live about an hour west of Tokyo, and built our house (2x4, imported materials from western US and BC) back in 1994. Unfortunately, our contractor used LP OSB siding (yes, the same one subject to a class-action suit), and it's starting to rot in numerous places, so I brought in a container last month with pre-finished Hardipanel and I'll be installing it this summer/fall, together with a couple of rooms of oak flooring, etc.

Home made scaffolding

If you hired me to do the job, I would just rent the scaffolding. Very inexpensive to rent. Most good rental places will have it. To go 16' you will need 6 frames, 4 safety braces, and 2 aluminum plank. You can rent it cheaper then you can buy the 2x4's. Scaffolding is nothing to mess around with. do not build your own.

Scaf rental price varies TREMENDOUSLY between locations.

For me, it costs $160 PER WEEK / PER SECTION.

I built my own, and will reuse about 1/2 of it on the project itself when I'm done with the scrambling around the outside part. Here is what i use for the horizontal planking - super cheap at the moment!

http://www.t-brace.com/order_page.html

Similar situation in my neck of the woods. Renting scaffolding arount here for a month costs about the same as purchasing it. Sometimes I can rent a man-lift cheaper that I can rent enough scafolding...

I won't use home-made scaffolding, since I have been involved in a scaffolding collapse on a self built set. Luckily, we were only about 6 feet of the ground and I got away with only a badly sprained ankle. For the relatively low price of buying scaffolding (especially compared to a doctor bill or taking advantage of your life insurance policy) I will never build my own. If you only need it for a few weeks, buy some, use it and put an ad in the paper and sell it to re-coup most of your costs.