I am researching changes in the way houses have been built since colonial times for a class I am taking on the history of the U.S. economy.

I am interested in hearing from you if you know of sources, or have insights of your own, concerning the materials and techniques used for home building and the way products and methods have changed over time.

I surmise that regionally available resources resulted in building practices that were far more market specific 200-odd years ago than they are today; someone building a home in a timber rich region might have had little trouble erecting a timber frame, while for a settler on the great plains a sod house may have been the norm, and in Arizona an adobe structure might have been prevalent. Today I suspect that houses are, one the whole, more similar than they are different by region.

Items that were considered luxuries – or simply hadn’t been invented yet – 200 years ago, like indoor plumbing and electricity, are now commonplace. These kinds of changes have had a very profound effect on homebuilding.

We all know about the impact of stick-built homes following WWII. What are other milestones you consider significant turning points in home building since, say, 1776?

I’d sure appreciate hearing from you.

Thanks,

-Jazzdogg-

“Don’t ask yourself what the world needs. Ask yourself what makes you come alive, and go do that, because what the world needs is people who have come alive.” Gil Bailie

Edited 2/3/2006 7:27 pm by jazzdogg

Replies

that's a pretty tall order! Here's one of my favorite resources. Oriented toward design schools, but just chalk-full of all kinds of historical insights.

View Image

"he...never charged nothing for his preaching, and it was worth it, too" - Mark Twain

Great book, that!

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

That's great reference. I pull it out frequently.

Birth, school, work, death.....................

http://grantlogan.net/

I wanted to take a moment to offer my heartfelt thanks to those of your who have taken time out of your busy lives to reply. You've offered insights that no academic source could provide, and the book recommendations have been invaluable.

Sorry I haven't been able to reply to each of you individually - this project and others have kept me running at a fool's pace this semester!

Sawdust in your shoes,-Jazzdogg-

"Don't ask yourself what the world needs. Ask yourself what makes you come alive, and go do that, because what the world needs is people who have come alive." Gil Bailie

Any basic Art History text (Janson or Gardner ) will

cover the basics. I think here on the list you

will see more about how and less about why. Both

are surely important and very interesting.

Don't forget mobile homes and prefabs.

My personal vote is for the mass production of nails and then screws. Nails were expensive early on and so much of the construction was mortise and tenon and plane made Tounge and Groove.

Nails and screws enabled houses to be put together faster.

Electricity helped reduce fire hazard from gas lines used for heating and lighting.

Cement for foundations, instead of rubble or laboriously cut boulders, or nothing, helped to prolong the life of the building and issues with settling (somewhat) but again increased speed and lowered cost for which a home could be built.1 - measure the board twice, 2 - cut it once, 3 - measure the space where it is supposed to go 4 - get a new board and go back to step 1

You might want to check out:

From Cottage to Bungalow: Houses and the working class in Metropolitan Chicago, 1869-1929 written by Joseph Bigott.

Chapter 2(?) goes into a fair amount of detail regarding tools, lumber, stock building elements like windows and doors, etc.

Wow, this could be a beautifully deep subject! I'm afraid I wsill miss most of this discussioin due to travel plans, but I'll subsribe to it.

In about 1830, mills became very common where finished products such as standard patterend casings and crown could be provided on a common scale. This co-incided with the advent of the Greek Revival design style which used detailing such as this. plain and bulky vernacular gave way to a new thing.

Mass production techniques have influenced this industry in several ways. Mobile homes and the better built modular and panel cosntruction of the past thirty some years are one way of seeiong these technigues applied, buit another is the specialization in the trades, where once a carpenter would be expefted to roof the house he built, but now it is subcontracted to roofers, which are further divied into shingle layers, BUR hotmen, and the newwer tech membrqane applicators. The mass production techniques apply intensely to your theme connecting to the overall economy, because it made home-ownershipo more common and more profitable and contributed a greater number of landed citizens to thje demographic make-up of our country. As Ford made ownership of autos psossible for the common man, so mass production made home ownershipo and the equity balance tied into the national economy.

The use of that equity has recently contributed to further gains in the stock martket which translate in untold ways to capitalization of business and American influence in the world. I imagine books could be written along this line of thought.

Good luck with yours

Welcome to the

Taunton University of Knowledge FHB Campus at Breaktime.

where ...

Excellence is its own reward!

Well I can't give dates, and I have no scholarly sources for these opinions. Therefore, these are just ideas for you to research. I can't say that these were actually significant. But, here goes.

Railroads combined with the industrial revolution. This made standardized materials more available around the country.

Offset printing. Reduced the cost of printing, resulting in catalogs.

Standardized sawn dimensional lumber. This precipitated a shift from heavy timber post and beam type construction to "stick framing". After the Chicago fire balloon framing first came into use.

Plywood.

Petroleum. Resulted in asphalt roof shingles, and for a time, wall shingles.

Concrete block. Sped up masonry, for example, in foundations.

Electric power tools.

Machine made glass. In colonial times when glass was handmade it was an expensive luxury. Only well-off people could afford to have many windows, and even then the panes were small.

This is a round-about way economics influenced homes: slavery. The south had a slave economy. Slaves came from Africa and brought with them different building ideas. In West Africa because of the heat, houses were built with porches. Slaves working as carpenters in the American South expanded on that concept to protect Southern homes from the heat by creating the veranda. Before the African influence, homes in America did not have porches, and in Europe still don't.

Different waves of immigration brought their own practices. Some were more influential stylistically and others resulted in functional differences in methods of construction.

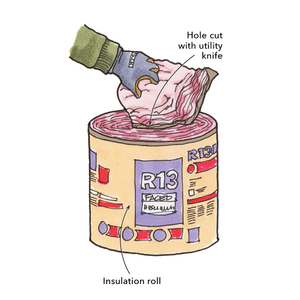

Lack of abundance of old-growth timber for harvesting. Hence, finger-joint studs, particle board, OSB, etc. Blending of modern technology with construction materials - i.e. plastic or vinyl wood substitutes. Increase of energy costs, with the technology to measure component effectiveness. R-value insulation, dual-pane glass, etc."he...never charged nothing for his preaching, and it was worth it, too" - Mark Twain

"Electric power tools."When did they sneak that in?

Wheere kin i git sum?

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

They are much handier than the hydraulic, bovine and equestrian power tools. But the new thing is electric tools WITHOUT a cord!

Colonial homes were built with mainly local materials, even the bricks were made on site. (Unless they were ballast bricks from English ships - warning, I think that may be a urban (colonial) legend).

I agree with Piffin that the developement of the saw mill was the the thing that changed home building the most, allowing production to flourish.

Also, a lot of people are unaware that most of that fancy Victorian trim was mass produced and ordered out of catalogs. Even the "carved" stuff was pressed at a factory.

Mike

Trust in God, but row away from the rocks.

Check amazon.com for a book titled The Framed Houses Of the Massachusetts Bay, 1625-1725, by Abbott Lowell Cummings.

I just bought a copy last month on the recommendation from someone on JLC forums. It is an excellent history of early timberframing, and architecture. As well as a brief history of early carpenters, and their tools.

--------------------------

It's only satisfying if you eat it.

I have worked on a number of homes that are 150 to 200 years old. I am in the southern half of New Jersey. I visit Williamsburg Va. about every other year or so. The construction is the same. Foundations are brick, rubble , or sometimes none, just sills,which actually are beams laying on the soil. The buildings on soil are in dis repair, naturally. The descriptions given are from my expierence, 45 years of it.Other areas of the country may have different practices.

Ater the foundation,whichever was used is done, then the walls are constructed. This is ballon frame for multistory homes. There are no wall plates. 8x8 or larger beams for the top and bottom are common. The studs are not nailed, they have a tenon that goes into a mortise, top and bottom. The walls are made on the ground, bottom beam on the foundation. At each top corner a 4x4 or larger member is mortised at an an angle from the stud to the beam.Effectively a cut in brace. When each wall is framed, then it is tilted into place. Temporarily braced. Joists, almost always undersized by todays standards sit on a ribbon board which is let into the studs.This is done before tilting up. The ribbon is usually a full 1" x 6", nailed. The material for the studs ranges in size from 2" thick to 5" thick, depth from 4"to 5" deep. All rough sawn, all appear to be either handsawn or with a sashsaw.

After the walls are up and braced, the siding or roof framing commences. Not sure which was most common. There is no sheathing, the clapboards are the finish siding and also a sheathing. Most homes here with original siding used cedar clapboards. They were not beveled, flat 3/4"x 7" with 5 " to the weather. The first clapboard went over a 3/4"x 1" starter at the bottom. This brings the bottom out, the rest of the clapboards are nailed with a wrought 8d iron nail.Each clapboard is full thickness,3/4" ,as opposed to the bevel of todays siding. The siding sometimes was smooth, usually rough.Once in a while i come across a smooth sided clapboard with a planed quirk. Only wealthier people would pay extra for this feature then.

Roofs had flat boards that served as nailers for wood shingle roofs.Becuase the homes were ballon framed, and a mix of timber framing, the floor joists could go in later. The walls were wood lath, some sawn ,some hand hewn.Plaster mix was a grey colored scratch coat, the final thickness averaged 1/2" thick.I rarely saw a whitecoat, unless it may have been done later.Not sure, nobody around to ask.

Floors were 1x6,8,10 sometimes wider,full 1" on 16" more or less centers. I should have mentioned that most framing was 16" O.C. The floors were usually heart pine, no subfloor, often tongue and grooved, by hand.

From talking to the carpenters at Williamsburg, the construction there and here were the same. This covers what I know from personal expeirence up to the rough work. I know very little of the interior work, most have been altered over time.

mike

I recently read a book Building Houses in New France. It is a bit of a sleeper for a craftsperson, but would be valuable for the research you are doing. As you can tell from the title, it deals w the early french settlements in Quebec. I took it out of a library in southern Ontario.

Both John Steele Gordon's An Empire of Wealth and Paul Johnson's A History of the American People go into great detail about the impact that the nearly limitless supply of timber resources had on American history. The balloon frame house, invented in Chicago in 1833, was the result of abundant timber, the industrialization of the process of sawing timber into boards, a shortage of skilled timber framers, and a pressing need for housing in Chicago and other booming cities.

However, wood framed houses packed tightly together in large cities led to catastrophic fires. In addition to the devastating fire in Chicago in 1871, fires destroyed much of Toronto, Baltimore and San Francisco in the first decade of the Twentieth Century. These fires spurred municipalities to hire building inspectors (the first building inspector in many localities was the fire chief) and to draw up our first building codes. These new codes did not permit wood structures in densely packed areas. Just as London was rebuilt in masonry after the Great Fire of 1666, cities in America were rebuilt in brick, stone and mortar.

My point here is that, while wood is extremely important in any discussion of American housing, it would be a mistake to limit your discussion to wood-structured houses. Afterall, Monticello is a brick house.

Ironically I'm reading a book now on the subject

http://www.amazon.com/exec/obidos/ASIN/0486417050/qid%3D1139089383/sr%3D11-1/ref%3Dsr%5F11%5F1/102-7062762-0245754

I bought it years ago and never came around to reading it until a few weeks ago.

It seems like a well written and documented book though I'm only about a quarter into it at the moment.

Check it out