Hello:

Hello:

I am installing modifiied bitumen self adhering roll roofing over my addition roof. I am installing a base sheet now, and will be installing a cap sheet as well. I have a question about how I should treat the valley shown in the photos below.

Method one: which seems good, would be to continue my laps right up onto the higher pitch roof, about a 18″, then shingle down the higher pitch roof to the transition.

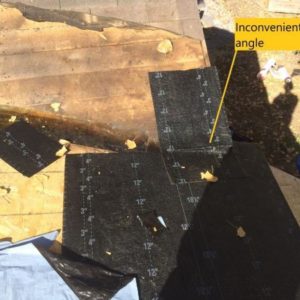

The drawback I see to this method would be that there is a bit of a rough 90 degree transition there, at the eve (about an inch) and I am concerned that I won’t be able to bend the cap sheet around all of that weirdness, it will blister out and possibly break there. See the picture.

If this is the best method, perhaps I should put some angled wood in there and smooth the transistion out.

The second method I could think of would be to put a wide piece of metal or bitumen valley flashing all down that valley, vertically, going up the high pitch roof 10″ and covering the low pitch roof 10″. My concern on that method would be whether the self adhering would stick well enough to that valley flashing, on the low pitch roof, or if it would pull up over time as all the water would be pouring into it, since the water will be pouring in from the side, right at the seam.

Any recommendations on method 1 or 2?

My second question is concerning some uneven seams in my osb decking. I left an 1/8″ gap, but there are some parts where there is perhaps 1/8″ bumps in the seems of the osb, where edges swelled a bit. I am concerned that those seems will telegraph through and cause premature ware on the membrane. I could cover the seems wtih tape, or extra strips of mod bt underlayment, just as added protection from them telegraphing through. I don’t think sanding OSB works too well.

Any recommedations on fixing those seams?

Thanks

Chris

Replies

I prefer metal valley flashing myself.

That first two foot section is a little wonky but you should be able to get decent results on your own forming sheet metal up and over the vertical hump and then I would run a normal valley flashing down over top of that first section. If you want the best results, call your favorite HVAC guys and have them custom make this section.

My roof has a valley that runs into the sidewall of the middle section of my house. My local heating contractor custom made a copper pan 23 years ago and it has never been a problem.

Hey there,

Common valley flashing procedure calls for running the self-adhered flashing membrane (Ice and WaterShield) right up the center of the valley from the eaves' edge to the ridge first. Then the Ice and WaterShield is installed parallel to the eave for each side of the valley lapped in near the center of the valley, but not up the opposite side. It looks like in the picture that the lower roof's membrane is leaving exposed sheathing below... that is not what you want. As for the small kink in the roof decks where they meet, you could ease that with cedar shingles first, or use a sheet metal valley that will easily span that void. The metal valley should have a hemmed bottom edge that gets crimped over the eave's drip edge so any gap is concealed. Not sure I answered any specific concern... Hope so.. Good luck.

thanks

Yes, that answers all my questions. Thanks to both of you!

Chris