We cannot get a TJI 9.5 110 series at over 36′ length, and our little plan has some long runs.

So, we are thinking of doing butt joints over some intermediate bearing wall situations.

The wallframes are 2×4, so we thus get the min 1.75″ end bearing specified by TrusJoist, if we center the butt over the walls.

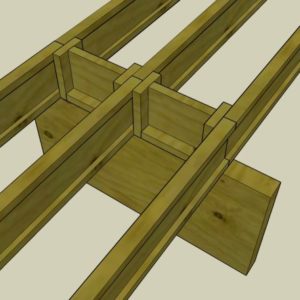

We’re thinking of blocking like this.

The bottom and side chunks are 2×6, which serves also to give us some ceiling finish backing. The diaphragm block is a rip from 2×10.

I’m waiting for a reply from one of TrusJoist’s engineers.

Have you buttjoined I-joists over intermediate bearings? What did you do?

Replies

I have done pretty much the same detail as you have drawn there Gene. Some minor variations with the blocking. You gotta watch out though... with only 1.75" to nail into, the chords want to split easy. To counteract this, I packed out the web flush, then sistered in scabs (2' + or so) of 2x10 to 'capture' the splice. This splice board can be toe-nailed nicely to the wall (or beam) below. By packing in the webs and then solid blocking in between (personally I would use I-joist for the blocking on top of (parallel to) the wall) you will also meet your fireblocking needs.

There...... clear as mud. :)

I understood fine and if I can understand it anybody can.

We pack out the web as well, all of the i-joist companies I deal with say that a 1x4 will do the trick just fine.

That would be fine, but it is a bit of overkill.

Have you looked at the TrusJoist installation manual?

With the new IRC code around here we have to block at all bearing points now, whether there is a splice or not.

All TrusJoist requires is another piece if I-joist butted pependicular up tight to each side, no filling of the web required.

I have attached a pic from the BCI install manual.

View Image

Edited 1/29/2007 4:37 pm by Kgmz

From the TrusJoist manual.

View Image

Those drawings show if you have full length joists. Not like Gene asked. He has to splice his, so in that case a web stiffener is needed.

According to both BCI and TrusJoist the pics shown are fine for a splice. The only time you need web stiffeners is with the tall 18" and 20" I-joists. And also the way they spec'ed them in the engineered drawings for the last two houses I built with a long 48' run and spliced. And my building inspector is sharp and would have caught it if something was wrong.

One of the long run houses was built 2 years ago before the IRC change and the other just framed last month. The splices were both handled the same, just a I-joist block. The only difference was all the blocking on all bearing points like mentioned in the first pic where it lists the IRC code.

If anything more was needed for the shorter joists you would think they would put it in the install guides, and the engineered drawings.

I get web stiffeners on joists smaller than 18-20". Probably a manufacturer difference.

I agree if anything more was needed the company that supplies the joists would spec. it.

Gene - it sounds like you have gotten good advice so far - but I am wondering why you cannot get the I Joists full length. That is one of the resons I use them - 44s were no problem on the last house.

TrusJoist makes them long enough. My supplier cannot handle them longer than 36 feet, though.

I'm stuck with what my local condition can handle.

Gene,

Why are you butting them? Why not run them along side each other? Then put either I-joists blocking or squash blocks.

I've never seen that done before. I only butt the two ends on each side of the room for sheetrock nailing.

Have you ever lapped I-joists?

>> Have you ever lapped I-joists? <<Gene,Yes, that's what I'm talking about. Situations like yours where you can't get one piece or when one side is 16" centers and the other side is 12" centers. Do it all the time.Joe Carola

We will only consider lining them up if it's going to save us work in putting on our plywood. What you can do to get good nailing and more importantly bearing, is to lap your joists the space between webs should then be two inches (1 inch per flange) A piece of 2x4 scrap and some half inch ply and you've got a solid bearing point for the wall above, and I usually try not to put blocks between for the sake of the other trades, however if your code requires blocks between joists than I guess there isn't any getting around it.

Joe,actually that message was intended for the original post. I've seen you're name in here plenty and I don't think I've ever disagreed w/ you.

This pic shows the joists, highlighted in gold, that exceed the length we can get locally. All the others are home runs.

View Image

Why lap them if you can join them? They have to be blocked anyway, over the walls.

Lapping them in this arrangement while having no laps for the homerun bays would cause us grief in our subfloor laydown, that we would rather avoid.

The TJ engineer got back to me and said a simple one piece block is sufficient. She also said the 1.75-inch bearing on half of the 2x4 bearing wall is sufficient to pick up the end reaction of the joist.

Looking at your layout drawing I saw something that reminded me of a solution for the same problem I had several years ago.

I asked the engineer if I could cantileiver the joists 1' and splice in the areas over the closet ceilings. Each joist gets full bearing with blocking on it's own wall, a short cantiliever for each and a slice gusset applied to each side of the webs worked.

Would it kill you to use a 2x6 wall?

Being that bearing is so much of a concern.yourcontractor@aol.com

It's Never Too Late To Become What You Might Have Been

TrusJoist got back to me and OK'd my detail, saying it was more than enough. A butt joint over a 3.5" wall is OK with them, as long as blocking catches both joist ends.

I've had an epiphany, and am now a green builder. 2x4 framing, 24 centers, I-joists instead of sawn, yadda, yadda, yadda. Particleboard cabinets, too.

So, yes, it would kill me to use a 2x6 of a 2x4 will do. ;-)

How did you make out so far as siting the house and the floor plan?yourcontractor@aol.com

It's Never Too Late To Become What You Might Have Been

See the attached, Eric.

For some reason I cannot open pdf's on BT today.

Could you email those to me?

I've given your post about siting some thought and I'd love to see what you came up with.

I know of a few homes that are backed into slopes and I wanted to take some pics for you, just haven't had the time.yourcontractor@aol.com

It's Never Too Late To Become What You Might Have Been

Nice detail on the roadside. I like it .

I don't think you should be allowed to use 2/4 for anything other than closets. We always make the bathroom wall 2x6 where possible even when it's not called for it's just easier for everyone that way. I've been on job sites where the rule was the south wall on all the houses got a layer of firecode drywall behind all partitions and inside of rimboards ect. On a 2x4 garage wall I'm only left with 2 inches in the best circumstances, when I lose the additional 5/8 to drywall I'm always nervous. I've been told 1 1/2 is enough. It really doesn't seem like it though.

""I've been on job sites where the rule was the south wall on all the houses got a layer of firecode drywall behind all partitions and inside of rimboards ect."

Why ? Especially why only on a South wall?

If you do a google earth of southern ontario, you will quickly see the trend of tonnes of houses jam packed into rows upon rows of identical houses. We have a rule, every seventh house is a fire break, meaning b/c the houses are so closed together until there is brick on them, the seventh house never gets built. SO after explaining that I could just sum it up and say the homes are so tight together fire is a concern. There is a limit to how close one house can be to another without using the fire code. At a certain distance you would actually require it on both sides, Typically for us it's only one, so if everyone does the south side there is no chance of two houses having two non firecode sides facing eachother. It's sort or a ridiculous thing b/c this rule doesn't extend to roof tops, sometimes having two large gable ends ten feet apart with no fire anything! I guess no one at the fire dept ever saw fire jump roof to roof.

Thanks, makes sense now. I was wondering if it was for fire protection but couldn't understand the one side only issue.

My pard says "can't we just use floor trusses, instead of those stupid I-joists?"

So I go to UFP's OpenJoist 2000 web pages, and what do I see?

View Image

RFQ went out via email this afternoon. We'll see how they look, price-wise.

We have gotten floor trusses longer than 36' before. I think on our townhouse project last winter the floor trusses clear spanned 32' or 36' can't remember exactly.

They wouldn't allow us to cantaleiver floor trusses, I thought I saw a cant. on the drawing. I had to swith back to LVL's and I joists for that.

Is there a reason you don't run the joists the other way? LVL and hanger the long side without a full bearing wall.

Gene,

We lap them all the time without any problems. Then you get full bearing. Like the one poster said, you may have to scab for sheathing, but that's not a big deal, we all used to do that with solid sawn anyway.

FOLLOW MANF. RECOMENDATIONS

Even if yours,mine + everyone elses ideas are better,faster,stronger.

Skip the bottom 2x6 piece which you say gives you drywall nailing. This is not a typical detail for any drywall installation, so why waste your time and materials in this case?