Hello all,

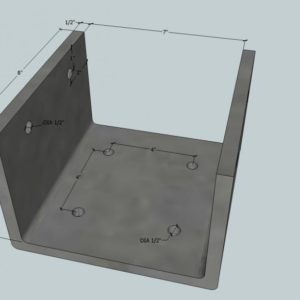

I’m in need of a bracket to hang something from a wood beam. I’ve attached a drawing that shows a general idea of what I’m looking for. I can provide the specifics if needed. The bracket needs to be able to hold a 50 lb item. It will also be outside, not directly in the elements but pretty close.

Is this something anyone here can do or could you connect me with someone who could?

Thanks

Joe

Replies

The bracket in your design could carry 5000 lbs.

If you need 50 lb capacity, it could be easily bent from 16 ga. galvanizied sheet metal, which would withstand exposure to any weather.

Check with any sheetmetal shop that does HVAC ductwork. They would probably do it cheaper than a machine shop.

Or do it yourself.

Get thee to a welder

If you actually want it made out of 1/2" thick material, take the drawing to a welder and see if they can either (a) cut you a chunk a C-channel that's close enough to your dimensions, or (b) snap three pieces of 1/2" plate on the ironworker and weld them together into your piece.

As correctly pointed out above, you could use heavy gauge sheet metal to carry the load you state. The HVAC guys I know don't keep anything around much heavier than ductwork, so I'd still go to a welder.

That looks similar to two Simpson BC40 connectors next to each other. Have you looked at those at the hardware store?

While I couldn't see your drawing, my local hardware store sells galvanized steel right angle stock already perforated for screw holes. This material will easily support hundreds of pounds, cuts with a Sawzall and bolts together easily. Perhaps it would work for you?

If you can't find a sheet metal shop locally to fabricate that, Simpson will make almost any custom hanger and get it to you within a week or so. I've been impressed with their turn-around time and perfect quality (dead-on correct angles and dimensions) when I've needed custom hangers.

k

Yeah, a welding shop, or find a sheet metal supplier that can cut the blank out of heavy-gage sheet and bend it on a brake. Even if it's just plain steel, you can prime it with a good metal primer and paint it and you shouldn't have to worry about rust for 10-15 years.

If you can't find a welding shop, ask at a car repair place for who they use for welding.

>>>The bracket needs to be

>>>The bracket needs to be able to hold a 50 lb item.

50 lbs is a pittance.

Are you sure you even need such a bracket? You haven't explained what you are trying to support, but if it's only 50 lbs, I'm wondering if you could accomplish the task with less expensive stuff, like an eye bolt through the wood beam, perhaps a U bolt, or some other simple arrangement.

Piffin screws!

Geez Joe, could have picked a piece o scrap section out of the steel pile, chop sawed off a chunk - faster than this reply.

I'll be going thru Rockford next week via ORD, will bring you a piece for pickup if you e-mail me the dimensions---and if you are that adverse to simple DIY.........bottle of rum in trade would be OK <G>

More details

Yes, the 1/2" is way too thick. I just picked that dimension when drawing it.

Yes, I could use two bracket instead of one.

Must be strong, if this thing falls, someone's severely injured or worse.

I've attached photos of the bell that's going up and the locations it's going. The bell is solid brass and 12" across.

Inside the wrapped beam is an LVL with a 3/4" cedar spacers between the LVL and the exposed cedar sides. Because the bell's top bracket has holes 4" apart, I can't go straight up into the beam with some type of lag bolts - I have no idea what I'll be hitting. I would also like more that just threads holding this up. I would prefer something going into the beam horizontally to avoid any material failures.

Hacksaw off the thread sticking above the nut. Center punch the nut to the thread (or apply epoxy to prevent the nut ever loosening.

I'm thinking your 300# BIL doing pullups, so you need to hold up 350*say a factor of 4safety margin.

5" of 3/8 lag into LVL will hold about 350#, so 4 bolts thru the corners of the bell plate would work - use 4 1/2" nuts and a thick washer as spacers. 3/16" pilot holes, but wax on the bolts before bolting in.

Prolly need to put the bolts in at an angle to catch tne lvl, glue an old water bottle cap or similar over the heads to look neat.

not my style, sorry

thanks for the response.

1 - there's a good chance that the lag bolts will hit the space between the layers, even at an angle. Then the bell is just hanging from the brad-nails holding the trim up.

2 - the stem of the bell is about two inches tall above the plate. I didn't draw it on the bracket, but I would need to account for that going straight up in to the beam if I didn't use a bracket of some sort.

3 - I like the look of a metal bracket. This new porch has a little too much cedar. I would love some other materials.

http://jmadson.shutterfly.com

not my style, sorry

thanks for the response.

1 - there's a good chance that the lag bolts will hit the space between the layers, even at an angle. Then the bell is just hanging from the brad-nails holding the trim up.

2 - the stem of the bell is about two inches tall above the plate. I didn't draw it on the bracket, but I would need to account for that going straight up in to the beam if I didn't use a bracket of some sort.

3 - I like the look of a metal bracket. This new porch has a little too much cedar. I would love some other materials.

http://jmadson.shutterfly.com

The bell is done. I used some angle brackets from the Lowe's decking aisle. There's actually four 90 degree pieces, I tried to make them look two U's. I painted them black. There's 4 lags going horizontally and 2 going vertically throug the brackets. The bell itself is fastened to the wood part of the bracket with for bolts and the main bolt on the top of the bell.

This thing is going nowhere.

Thanks to everyone for the sounding board help.

Joe

Well, ring my chimes!

Looks good!

Is the bell going to be rung, or just hang there looking pretty? If it's going to be rung (even if the bell itself is stationary) it does indeed need a significant safety factor (though half-inch steel is still probably overkill).

You do want to be sure (somehow) that if you drill holes through the beam they won't be just catching the bottom 1/4" of the wood inside. But because of the way the beam's built up you do probably want to through-bolt vs using lags or such, since the lags would likely squeeze the "skin" and be unsightly, if not unstable.

I'd suggest you find someone to make you something out of about 10 guage steel, either bent on a brake or welded into the U shape you need. Just ask around to find a shop -- there's always one (though perhaps in the back shed of some farmer), since this is the sort of work that is needed everywhere from time to time.

why not

just put lag bolts up through the existing plate into your beam? That bell looks heavier than 50 lbs. But whatever. If you don't have room for 4 bolts, turn your bracket at a 45 and just use two lagbolts and washers.

Else ... go to your local steel fabricator ... 1/2" plate will likely hold about 20,000 lbs or better. ... but like you said, it was just a drawing concept. The steel fabricator could use standard steel sections, weld you what you want, or take some flat 1/6" steel plate and bend it to what you want. Do your own holes to minimize cost.

Testing

The attachment method should contribute to the overall aesthetics of the bell - I would suggest making this up of iron strap material - two pieces bent into u-shapes to accomodate your desire for horizontal fastening. Two lags on each vertical leg into the beam (for eight total) is more than enough - remember you can buy picture frame hangars that can hold 100 pounds ;o)

Here's an idea. Redesign the bracket to be only about 1 to 1.5" wide. This will use only one thru bolt into the LVL. Take that square plate off the bell and fasten the new bracket directly. That square plate is way oversized in relation to the bell anyway.

This will accomplish your desire to thru bolt and give a more aesthetic appearance to the whole shebang.

You can make the narrow bracket yourself by cold bending some steel flat-bar in your vise. 3/16" stock will look nice.

I'd be tempted

to find out if there was a stair rail bolt the same size as that the plate is fastened to. Remove the plate, run the rail bold into the beam, attach the coupling (brass would be nice), size the end of the bell bolt and run that into the couplling.

Still need the bracket?

Also, you could rotate the base 45 degrees and just use two holes in the center of the LVL. Two lag screws is plenty to hang that rascal.