Installing Vertically Running TG Siding

We’re looking into using tongue and groove cedar siding (1×6 running vertically, not horizontally); but I’ve had little luck in finding any documentation about installation (most references are for horizontal siding). Questions include blocking/furring req’s, nailing schedule, trim and flashing details around windows, and corner details (for flush corners).

Anybody have any suggestions?

Thanks

Replies

Generally I attempt to dissuade the use of T&G for exterior siding due to the wicking effect of water through the area of the T&G. The tight fit does not allow for proper drainage. Expansion and contraction also is a problem.

Your materials supplier should be able to provide technical application data from the manufacturer of the T&G. I think the tech sheets will not reccomend T&G as exterior siding.

Take a look at the application specs on Reverse Board & Batten, or Ship-Lap.

...............Iron Helix

Thanks for the heads up

If asked to install vert. t&g for exterior siding, I would refuse. Ship lap is o.k. as long as EVERY surface is painted. You must also nail the ship lap fairly close to keep it from curlying open(smiles). I like board and batten on strapping every 18". You should also paint all surfaces. Don't try to hard to keep the boards tight. the battens will cover quite a lot of gap.

Flashing could be done by slotting siding above the head piece and then sliding the flashing into a bead of caulk that you put in the slot. Then the flashing should roll over the leading or outer edge of the head piece.

Just a thought.

Curly

Hand Hewn Restorations Inc.

Restoring the past for the future.

I would also suggest staying away from T&G siding.

Maybe it's not so much a problem outside, but inside my house I have some T&G. A long wall which ends at a door jamb. The door won't shut in summer do to the wall expanding

be sure to leave some expansion room around your window and door jambs.

I sided my house vertical board and batton and there was an excellent FHB article about 4-5 years ago showing details of flashing and trimming. I used the plans as set forth with excellent results. If I find the article I post the link

It is hard to imagine that the wall is causing that. Wood doors typically expand up to a quartter inch or so in summer humidity, but wall finishes normally stop an inch away from the jamb and the gap is covered by casing. It is really more likely that the door swells enough to cause the problem, and it can be planed to fit..

Excellence is its own reward!

it's a steel door to my garage

Then the problem is in the T&G installation. It should not be tight to the jamb like that..

Excellence is its own reward!

exactly,

like I said in my first post

Neighbor has it, also has rot problems from water getting in.

I'm sorry. I missed that line in your first post somehow and thought that the reason you were recommending against the T&G was the swelling to the door.

My goof. Your point..

Excellence is its own reward!

No biggie,

It's hard to catch every point in every post

I've never seen any documentation, but here's something you should know......

Paint, or at least prime, the tongues BEFORE you put the siding up. No matter how tight you hang it, the stuff will eventually shrink, and the tongues will show. And if they are painted, then they will still be "invisible". If they aren't, then they will be ugly as the dickens.

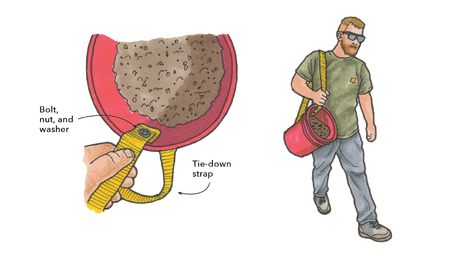

Used to install a lot of this pattern for a particular contractor. His grand scheme was that you could use your regular finish nailer to "stitch" the stuff in place by nailing in pairs, one angled up and one down, preventing the material from backing off. This was done right over 7/16" OSB ( you know, the $16.99/sheet flat gold), paying no attention to any blocking, furring, or other nailers.

Withing 2 weeks, the material was all cupped, witn 1/16 - 1/8" gaps between boards. This was all a real good grade of cedar. So my suggestion is, don't do it the way we did.

I did like the minimal detail he used around windows, though. No trim whatsoever ... just cut in the siding tight to the window. It did look rather nice.

The High Desert Group LLC

If you were going to paint it anyways, I wonder if there is a synthetic equiv material.

My neighbor has interior T&G in a bath made of a really nice dense synthetic material. Less expansion and contraction in a bathroom environment. Something similar might stand a chance outside.

Gravity is working against you with vertical siding. The seams will soak in water by surface tension, the fastener holes will soak water, and the lowest point is absorbant endgrain. The T&G area will not dry quickly or evenly.

You would need a really good drainage plane behind it. Perhaps soak epoxy into the bottom engrain to prevent wicking. Then all of the blocking issues which you know about. A lot of trouble. Unless you need to restore or match something already on the house, it's hard to imagine this being worth the trouble.

There is a beaded board version of Azec T&G about 3/8" thick. I don't remember if the back side is a usable surface for smooth work.

Excellence is its own reward!

I just finished replacing/repairing siding done this exact way. It held up for the most part for 20+ years. The problem (that caused the replacements) was water wicking up from below (the ends of the boards were not sealed causing them to rot) and it had gone years without being painted or otherwise treated. It was nailed to horizontal furring strips that were placed too far apart. Where it did not catch a lot of heavy sun, it held up well, with little or no damage, but in the full sun damage could have been prevented or at least greatly reduced by correcting all of the errors mentioned.

john