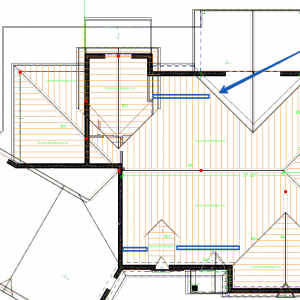

We are building a custom home with hip roofs and had some questions regarding the best way to support the roof in some areas. The span is 45′ across and the pitch is 8:12 with a 16″ overhang. We are planning doing 2×12 rafters and 14″ (4ply) LVL for main ridge, 3 ply for hips. The 45′ width puts the longest commons at around 29′ but most are shorter. Obviously doing LVL rafters is easiest by quite costly. Since we are planning to finish part of the attic space, we will have a tall knee wall about 5′ in along the perimeter of the attic. In our area of midwest, 20-22′ length on 2×12 is about all we can get so we were considering joining a 20 plus a 10 or 12′ rafter over the knee wall. I’d have no concerns if knee wall had supporting wall under it but it will be 3 1/2 TJI 560 x 11 7/8 deep below. We can pass some load down but don’t want to pass all roof load onto floor joists. Is there a way to join the 2 rafters together so the rafter still mostly works as one member with kneewall supporting at the joint but not getting 100% of the load as if it were a hinged joint? Our other thought is in areas where maybe we have 6 or so of these long rafters, every 2 or 3 use a long LVL as rafter instead and then block between the lengthened rafters – tying them together. Just looking for input to see ideas on how to best do this.

Discussion Forum

Discussion Forum

Up Next

Video Shorts

Featured Story

Get expert guidance on finding a fixer-upper that's worth the effort.

Featured Video

How to Install Exterior Window TrimHighlights

"I have learned so much thanks to the searchable articles on the FHB website. I can confidently say that I expect to be a life-long subscriber." - M.K.

Fine Homebuilding Magazine

- Home Group

- Antique Trader

- Arts & Crafts Homes

- Bank Note Reporter

- Cabin Life

- Cuisine at Home

- Fine Gardening

- Fine Woodworking

- Green Building Advisor

- Garden Gate

- Horticulture

- Keep Craft Alive

- Log Home Living

- Military Trader/Vehicles

- Numismatic News

- Numismaster

- Old Cars Weekly

- Old House Journal

- Period Homes

- Popular Woodworking

- Script

- ShopNotes

- Sports Collectors Digest

- Threads

- Timber Home Living

- Traditional Building

- Woodsmith

- World Coin News

- Writer's Digest

Replies

Talk to a structural engineer

Sounds like lvl rafters as you mentioned is the best option. The question is always how much weight does the knee wall and floor joints below it actually take. That isn’t something you can calculate in the field. One thought if the knee wall is a header you can transfer the load around the knee wall. All in all expensive lvl’s are probably cheaper than hiring an engineer or using a bunch of other materials elsewhere.

Thanks. The header is a good idea as there are a few areas we can do that. The biggest issue is we don't have continuous walls under where our knee walls are located. We do have an engineer looking at this but he stated doing calcs of knee wall load is difficult because many factors can vary load. He does feel that an overlap with good nailing over a knee wall will take most of load but would never recommend w/o the knee wall. I just want to make sure we don't overload joist below if knee wall does take more load than anticipated. That was partly the reason for using some full length LVL's as well. I was trying to find out what a 11 7/8" LVL x 1.75 rafter would deflect over roof span of 22 1/2 feet under typical roof loads of say 50 PSF but could not find it. I'm sure it is stronger than a 2x12 rafter.

I would think your engineer would want to spec the joists below to carry any loads the knee wall can deliver.

We ended up doing that. We used Boise Cascade's TJI calculations to build a scenario where we simulated the knee wall over the joist with the joist taking 100% of the load at that point which is worst case scenario and should not happen unless our joist -joint fails. Just looking for input on best way to splice the 2 together. Thinking a 30 - 36" overlap with a lot of nails over the knee wall.