I’m trying my first tile project in my house’s bathroom. The house is from the early 1900s and has the normal settling and out of plumb you’d expect from 100+ year old house.

The bathroom has the original pine tongue and groove wood floors and then 1/2″ plywood was added sometime in the 90s with vinyl flooring over that. I removed the vinyl. Scraped off all of the old adhesive. The plywood is in good shape so I decided to keep that and then put down a Nobleseal TS membrane to tile with 1″ hex.

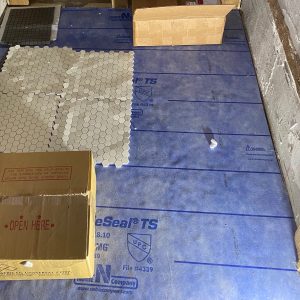

I put the Nobleseal TS down using NobleBond EXT and rolled it out, but it turned out lumpy. I’m not sure if it was from walking over the membrane as I rolled it, not being skilled at spreading the adhesive, or using too light of a roller. It doesn’t seem to be from any dips or imperfections in the plywood because it’s consistently lumpy throughout the membrane. The lumps aren’t air either because if I press on them, I can feel the adhesive squishing.

I have about a 50-50 split in advice for what to do. Half are saying that don’t worry about the lumps because when I put down the thinset, it will smooth out the imperfections and then I can level the tile in the thinset. The other half say that 1″ tiles will easily show any imperfections in the surface and it will be a nightmare to rely on thinset.

Wanted to see if the substrate is botched and I need to start over or can I tile over the lumpy Nobleseal TS and rely on thinset to get fiat tiles? I attached a few pics to see what type of lumpiness I’m dealing with.

Replies

Ask Nobleseal if you can pour self leveling compound over their membrane and then thinset to the self leveling?

Or instead of thinset do a full mudset of the floor but that assembly will be thicker and you may have a transition problem or a step at the threshold.

Basically call the manufacturer first and try get their recommendation.

I looks to me like there was too much adhesive applied, and /or insufficient time for the adhesive to set up before applying the membrane. In either case, rolling would have pushed the adhesive sideways into those bubbles. The adhesive should be thin enough and tacky enough that it does not spread when the roller is pressing the membrane down.

I would pull that membrane and start over if possible. Practice on some extra plywood to get the correct adhesive thickness and tack before working the floor.

If you are going to use the existing membrane, a skim coat of thin set over the membrane will level it out for tile setting. Those "squishy" bubbles will have to harden before skim coating. Could take awhile as the adhesive has to dry through the floor.