Found on Craig’s List – older (real) Bridgeport vertical mill (42″). Only a few miles from here; long-time local machineshop closing down. Talked to the son; his dad ordered it way back, before they had three-phase, so it’s wired for 120/240!

Good amount of tooling and a couple vises; they can set it in my P/U with their shop crane.

It’s currently powered up and working; I’m supposed to meet him over there tonight to check it out . . .

$2500, he says.

I’d offer a good bit less.

Forrest – missed another chance at one, one time.

Replies

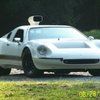

Wow... looks real pretty! Always wanted one to play with. I'm still astonished that they went out of business, I was at their plant once and it was just amazing how big it was.

PaulB

I have a small miller you can have if you're up for it. its a Burke, about half the size of a bridgeport. it goes horizontal and vertical. kind of a hobbyist machine

its got a 3 phase motor on it.

my wifes uncle gave it to me about 20 years ago and I never used it.

freebie, just get it out of my garage. can easily move it with a pick-up

Wow... I'd be really interested. Not to look a gift horse in the mouth, but would you mind if I gave you a ring to get some info? An email with a phone number?

PaulB

I can't count the amount of times I wish I had a miller in the shop. At 2500 or less for a single phase unit your doing well if the X and Y are tight. Even better if the spindle bearings are quiet.

His price would be fair, even if it were a well-worn, neglected Bridgeport, with no tooling!

Before you take the plunge, there are three issues you need to consider: power, accessories, and tooling.

Power, as in: what do you have, and what is available? A 2hp motor will take 20 amps of 240, and be affected by every other glitch in your homes' electrical system. Also, single phase motors start getting expensive.

Assuming that, sooner or later, you'll need to replace the motor, I'd consider changing over to three-phase, and powering it via a frequency drive. This will give you much better speed control.

Accessories are things that you'll want to mount to the machine. They include: Digital read-out, wear plate for the table, coolant mister, plenty of good lighting, vises and soft jaws, locking disconnect, and sundry clean-up materials.

Tooling is best described as a bottomless pit that consumes any excess money. Whatever tooling comes with it, it won't be enough.

You noticed that I mentioned a locking disconnect. Simply put, a mill is an extremely powerful machine, that will hurt someone very bad if given a chance. No one should attempt to use one without formal training in its' use ... if nothing else, a community college course. Operating a mill is not something you should try to teach yourself.

Thanks for the advice. My first training actually WAS a night community college course, at 15, then a couple years of metal fab in HS, back when we had a great vocational program in the '70s. (All the nerds took AP classes in the afternoon, then.)

Not sure if I'll be able to get there tonight. Got a buddy who's a pro-machinist-god-millionaire (http://www.boonerings.com/); gonna' try to get him down to check it out.

A lockout's a good idea; I've got three kids.

Shop has a 100 A service, and the mill would sit just beside the panel.

Forrest - Mr. coolant

Forest,

I have been looking for one myself, and I would jump right on that one for $2500 ! I have 3 phase at the shop, but was actually thinking of getting it for my home garage which is only 1 phase. I would not worry too much about thcurrent draw..... unless you are going to be doing some real heavy cutting in hard materials, you will probably never be taxing the motor to its full HP. Startup might be a quick spike, but that would be it.

If it wasnt in GA I would be down there in a second if you didnt want it.Bill Koustenis

Advanced Automotive Machine

Waldorf Md

Your 2hp 20amps seemed high, my table et-22 in an old Code Check shows 240v 2hp at 12FLA and 2880v-a. Am I reading it wrong or were you looking at LRA?

Bob

Just a wild guess. I stand corrected. Still ... however you define it, 2 horses can still kick mighty hard :D

Nice machine. I'd jump on that deal in a heart beat.

I'm moving to the country, I'm gonna eat a lot of Peaches. Aug. 8,9,10th Follow me.

http://www.youtube.com/watch?v=19McuaPKjI8

Forrest,

Looks like a good buy. I would do it.

Chuck S.live, work, build, ...better with wood

You want that. You totally need that. $2500 is practically a felony, receiving stolen property. My best friend from home had one in his basement... his dad was a prototype maker for Federal Mogul... and he made some really bitchin' marijuana paraphenalia on it, all nicely turned brass and so on. I still have one somewhere. Ssshhhhh!

I got curious and checked out your website. Great work, and a wonderful family it seems.

Thank you, much appreciated!

McDesign

Just for value purposes a new vertical mil that size sells for $2795 from Grizzly. Now add the value of the tooling and you have the cost of new..

From the sounds of it it's likely to be in decent shape but check for slop and wear. It's expensive to recondition vertical mills and a lot of them are pretty badly worn requireing more than you paid for it in reconditioning costs.

I've owned a vertical mill. It had been made around the late 1880's and been driven by overhead belts and converted to electric drive.. It was a wonderful thing to work with and I did a lot of work with it.. However it was too loose to do really precision work. The standard check is to slice a cut off a piece of steel the whole length and check for accuracy and the quality of the cut..

As for the tooling check it carefully look at the cutting edges with a high powered magnafing glass to see what sort of shape they are in. Dull edges require expensive sharpening.

One final point, older Bridgeports have a romance about them all out of proportion to their true value today. It's sort of like buying an older car.. one clean and fresh from a restoration shop is a very nice thing. However if it's older and worn out and needs to be restored the cost of buying it and then restoring it will greatly exceed what you can buy a great one that has already been restored.

Frenchy,

with all due respect, i don't find it credible to mention Bridgeport and Grizzly in this type of comparison.

Kind of an interesting thread, in the tangents you can go off on ... Lest I begin to bore folks ... let me repeat ... mills are very powerful, and can hurt you bad - don't try to teach yourself. Pay extra attention to securing the work, and take lots of tiny cuts. Tooling isn't what it used to be, and sharpening worn tools is a thing of the past. Here's where another accessory comes into play: a power feed. "Feed" and "speed" are critical, both for quality work and tool life. I suggest you get familiar with firms like Enco and MSC Industrial Supply. Others include Rutland (Air/Gas), J&L Industrial Supply, and - perhaps most important of all - your local machine shop supply houses. Finally, don't start off as a 'precision snob.' For the most part, your accuracy will have more to do with your set-up then your equipment, and you (personally) will be almost irrelevant. Also, for the most part, accuracy in the HUNDREDTHS of an inch is plenty good. Let the machine shop snobs scream - greater precision usually isn't critical for the home hobbyist.

As a former tool and die maker your chicken and I'm a far cry from a snob. I had to work in thousands as a freshman in exploratory (3 weeks classroom, 3 weeks shop) and never cut a piece of steel in my life. It's not rocket science.

What you really left out was safety glasses.

Thanks for making my point. When you learn a trade, you work under the supervision of a master, and he sees to it that your first tasks are pretty much 'apprentice proof.' One does not become a tool and die maker overnight. Likewise, the 'shop projects' you are given are how you learn basic tasks. I think every 'old time' machinist had a toolbox full of vises and fixtures he made as an apprentice. (His mother probably had a really spiffy meat tenderizer, too! :D ) As one progresses through the trade, he learns to set up the machine, perform more complex operations, and -these days- programming. Also, the tolerances get tighter. Also - not to be overlooked - is the extreme amount of specialized tooling used in industrial settings. It's very possible to encounter machines that are able to do only one operation, on one part, with one custom tool. That's all that monster machine can do. This is a far cry from a 'universal' tool like a Bridgeport.

Oddly enough ... I remember in the late 70's, when Detroit started to crash .... there were plenty of fully certified 'tool and die' men who couldn't find work - simply because their entire careers had been spent making that one part, on that one unique machine. Well, I wander. During your career, I'm sure you were around when, at some point, a workpiece was flung from a machine - leaving a hole in the block wall. Or, when someone lost a finger. Or, when that 1" thick solid carbide tool went 'snap.' Think of the power that it takes to do those things.

When operating properly, machine tool make it all look so easy ... it's easy for the operator to forget just how much force is being used. That is the kind of thing that will get you hurt. Heck, I've even seen some awesome cuts inflicted by shavings from nice, soft, aluminum. One almost wonders why they don't make aluminum razor blades. That's why I speak so strongly against the "you can figure it out" mindset. There's a very real value to having a teacher.

renoseinke

You could be correct, for some people.. Some do need lessons and teaching and even then are massive risks to themselves and others.

I did all my own teaching, made a lot of parts for my own race cars and never had an issue.. (mind you that's on vintage sports cars capable of massive speeds where my own life was at jeopardy)

I know I'm not the only person to do so..

Yes equipment can hurt or maim or even kill. But some people have common sense and can figure that out for themselves..

It's still no reason to discourage someone from buying a Bridgeport miller.

Most of the parts that went flying across a metal shop were from our own hands. Amazing how pissed off a craftsman gets when he F%&*$# up a part.

I say buy that miller if it checks out and enjoy learning something new. I can still count to 21. (with my gut sucked in) Not bad for a bunch a party animals at work. All power tools have DANGER written all over them. I'll bet table saws have claimed more digits than milling machines.

Enjoy life. This ain't no dress rehearsal.

I'd never discourage someone ... a Bridgeport is a true joy, a miracle maker if there ever was one. It's just not a toy. You can buy a saw, or a hammer, and that's all you need to saw, or hammer. Buy any kind of machine tool, though, and you better be ready to spend a lot of time learning it, and a lot of money using it. I don't want someones' eyes to get bigger than their wallets.

don't argue with frenchy he knows it all <g>

I was thinking the same thing

1 is a knockoff and the other the real deal.

Go for it Forrect! Enco is on the northside of ATL and got reasonable tooling although not the greatest. depends on what you want.

sharpblade.

Why not? The choice between a possibly worn out piece of equipment and a new piece of equipment? I've bought a lot of Grizzly wood working equipment and in spite of all the neigh sayers it's been great. Near flawless 7 years later and after over 40,000 bd.ft. of hardwood..

I am aware that some of the chineese imported stuff by harbor frieght and etc. isn't very good, however Grizzly does seem to be the exception..

If you are going to compare "new" prices, then let's compare new US made to new US made.

Excluding a milling machine (never used one), I have not used a Chinese knockoff tool that was equal to the US or German made standard.

Yeah, it may do the job, but it still isn't the same.

danski0224

Ok I'll agree with that statement.. most Chineese made stuff is still inferior in quality to a lot of well made American or German machinery. It's rapidly getting near the Japaneese equivalent which as you know in some cases is superior to the machinery made by American and German companies so it has improved by great amounts even in the last 10 years..

I didn't suggest that he should buy a Grizzly instead but gave him the price of Grizzly for a comparison..

That said, worn out Bridgeport to new Grizzly my choice would be obvious.. I used a well worn vertical mill and am familar with how to compensate for such wear. Knew how to fix such glitches as poor surface finish and in general made it work.. however buying a badly worn piece of machinery to a new piece of machinery I wouldn't hesitate to buy the Chinese import.

Same with tooling.. often the price of reharpening dulled tooling approaches the cost of replacing it.. Some are set up with the various grinders and equipment to resharpen themselves so the point is lost on them. I presume based on the OP's post he's not in that position.

Mc,

renoseinke is telling you the correct stuff.

I've used several Bridgeport's over the years, including the model you are looking at.

Absolutely wonderful machines! that goes for the clones and knock off's too. Extremely versital, many different things you can do with the correct tooling.

It sounds like you are going to be a home / personal use type of thing? ( same as me )

A couple things,

1) Enco = good ( especially for guy's like us )

2) Yeah it's not rocket science, but it can hurt you real bad, real fast. Get some training if you need it.

3) What size truck do you have, that machine just may be to heavy for 1/2 ton pickup

4) Tooling = $$$$$$. You could easily spend another $2500 on tooling depending on what you want to do.

Have a blast! Making something you just can't by, or repairing something that most folks would give up on is very rewarding.

Bill

Unlike the others who have replied - I have never used a milling machine.

My comment is much more mundane:

they can set it in my P/U with their shop crane.

I trust you have a way to get it out........in one piece? :-o

I figured you had that solved already!

Jim

>> I trust you have a way to get it out........in one piece

I've bought a few stationary machines in my life where I had help loading it in. Once home and often with no friends around, I've diasassembled the thing into manageable pieces, moved them alone in the shop or basement, and reassembled (often following a tune-up, cleaning or what not.)

Never with anything as heavy as a bridgeport...

I'm confident I can dissassemble / lift it out. Bigger issue is price - I'm trying to wait him out now!

Forrest - here's hoping

Forrest, Bruce here. I found the thread from my SiteMeter when people were clicking on the site. You still need to come by and check out the shop and have the family swim. The next equipment for me will be a laser microwelder. Fun stuff.

A real live Bridgeport in relatively good shape will definitely be worth the cost. Don't let the deal go by because of the cost. It can pay for itself pretty easily in increased capabilities. This is the real deal. There are others at Enco at the price, (like mine) but they are the imitation, and they won't have the tooling. My tooling philosophy over years of tuition at the School of Hard Knocks and Electrical Shocks says to get the best equipment you can afford at the time because you will later find ways in the future to creatively use that equipment in ways that you can't now realize. I certainly never thought I'd be doing what I do for a living. Only because I kept my original CNC machining center was I able to make rings, but had to get somewhat creative tooling wise to do that. That later allowed me to get the lathe, and make them more conventionally and to increase efficiency.

I also worry about the load in a pickup. Don't underestimate how heavy or TOP heavy that is. It will raise the center of gravity of the truck considerably. It might be worth getting a U haul or something stiff just for the trip. It still beats paying riggers hundreds of dollars per hour.

Don't forget the 3 phase. You can get by with a small rotary phase converter or even one of the static ones. I think I still have the original one I ran my mill with in the basement. The machine itself won't eat much power, so if the phase converter is only for that machine, it doesn't have to be a big one.

For anything machine related, if you're not familiar with them, get familiar with Enco off 85 at Beaver Ruin and MSC, near Six Flags, which has a 4" thick catalog. Anything you need is there the next day when order until 9pm.

Hey - that's great you found this! I try to pimp your name whenever someone's getting married. Still deciding if I "need: or "want" the mill. I'm letting it sit in my mind for a bit.

Bridgeport site says it's ~2200#; I have air springs on the truck and have carried ~4000# reasonably level, and do have a steel rack to brace to.

Love to have it, but am trying to be realistic about my use of it. Yes, I could have some hot rod fun with it, and we are going to a 4x10 workweek here, and I certainly can fabricate some prototypes - light fixtures will have to move from sheet metal to castings, for heat-dissipation with LEDs.

We've got to get together - kids start in this week; hard to believe.

Forrest

Not sure if you have any buddies in the machine tool world.

It'd be real cool to find a used proto-trak. We have a couple here at

work it's amazing what you can do with just a bridgeport equipped with one of

these. Especially for prototypes.

http://www.southwesternindustries.com/swi/prod_Prototrak.shtml

Perhaps ebay? Just a thought.

-D

I would get a low trailer.Keeps the weight down low.And if you get on with a rampe or tilts you can get some pipe and roll it off..

.

A-holes. Hey every group has to have one. And I have been elected to be the one. I should make that my tagline.

BillHartmann

Even a extremely low trailer would tilt that massive vertical mill at a dangerous angle rolling off it.. they are really top heavy and the base isn't that big.

I have an engine hoist I got for my last machine, a Tormach small CNC mill, which was somewhere around the same weight. Forrest, you are welcome to use it if you like.

Anybody who has moved a miller knows to turn the head upside down and block it. Makes most of the top heavy go away.

Good to know!

Forrest - still thinking

I can only imagine Forrest with a mill. I get scared just thinking about it. :o) The way I look at it, it's something that you would always have, so the payoff might not be now, or 2 years from now, but maybe in 13 years when your son can also use it. You have no clue what you'll be doing by then, but at least it will be paid for and you'll still have the full capabilities of it. I got mine in 1985, and I still use mine each and every day. There's no way I could have forseen what I'd be doing with it. When you consider "want" or "need" the equation doesn't include those variables. I know for a fact that you would use it to do crazy stuff. And I mean that in a good way. You always have to be into 10 projects at once, and this thing can help with about half of those.

I have a good friend that says: Anything worth doing is worth overdoing. :o) I try to live by that motto myself. Sure, I'd also recommend the CNC mill, but you have to start somewhere. The vertical mill was my first machine. It allowed a lot of freedom in creating prototypes of inventions and stuff. As you know, that's a pretty big deal. It can also allow you to make and sell stuff on the Internet. That is also a big deal. I can promise that once the sting of buying it is gone, you will never regret it.

btboone

That's good advice.... for yourself.. I too had a vertical mill and I used it for a long time.. finally at one point I looked at it as a dust collector and a piece I was unlikely to use effectively much in the future and sold mine. The good thing is there is a bottom price for all that sort of equipment and once there you never really lose money, just let someone else hold onto it for a while while you use it.

Another words don't be afraid to buy it and find out later you don't need it or want it that much. Most likely it will retain it's value enough for you to get your money back..

That's a good point that I meant to touch on. This particular mill might sell for around the same, or maybe more money in the case of having to move it. I just wanted to stress how cool it is to be able to make stuff and sell on the Internet. Once the infrastructure is in place, anything can happen. Today's just a normal day and we might do around $3000 worth of stuff and get done by 4:00. It takes some imagination to think outside the box to come up with something that might sell, but it is so empowering to be able to do that, even if it's for a little bit of side money to buy more toys. There's also very little cost or risk in doing so.

Here's a prime example: http://gizmodo.com/gadgets/portable-media/iwood-now-offering-hardwood-cases-for-ipod-5g-160394.php

Wooden iPod cases for a little more than $100. They can be made on a mill.

Edited 7/30/2008 8:40 pm ET by btboone

McDesign

I removed a similar sized vertical mill from the bed of my pickup with a really well made engine hoist I'd made. That allowed me to roll it into my shop and set it down where I wanted it..

However don't attempt that with just any engine hoist. Most of the engine hoists I've seen won't do it..

Today I'd go up the street where they're building a house and get them to come down and lift it out for me. If that weren't around I'd see what the local rental yard wanted for large Bobcat for a hour or so.. the small ones won't be able to handle it. Except for John Deer which uses a differant lifting method that gives it a lot more ability to lift heavy things..

How much did they want again??

http://seattle.craigslist.org/tac/tls/775316277.html