I’ve asked this over at the JLC forum as well, so if you visit there, you’re seeing double.

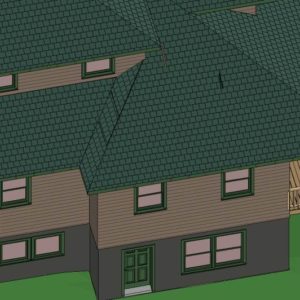

A section of roof frame may be either sticked or trussed. See the pics, attached, which show the roof and its layout. In the layout, the truss arrangement is shown, but if sticked, layout would be about the same.

The only diff would be at the hip and valley of the jog.

Stickframed, the job requires both rafters and ceiling joists, all on 24 centers as the trusses are shown. The pic highlights the “bast*rd” segment, made necessary by wall layout. All is 6:12 except for that, which is 8-3/16″ pitch.

Give us your best estimate of total MH to do it either way.

Replies

To install the trusses or complete job?

MH to set and brace trusses.

MH to cut and frame if sticked, instead.

It's a cost study in stickframed versus engineered trusses. I have the material costs for both, and am interested in hearing from those experienced on the labor end, so I can estimate a total.

View Image

"A stripe is just as real as a dadgummed flower."

Gene Davis 1920-1985

15 man hours to set trusses, and brace, + a crane.

What does MH stand for? OK, got it now from context of other replies - We framed one on addition about that size yesterday. One bastard hip and one normal.Three guys, seven hours, and had to carry lumber long way in from the street on a narrow lot.And we only frame a hip roof once every 8-10 years.

Â

Welcome to the

Taunton University of Knowledge FHB Campus at Breaktime.

where ...

Excellence is its own reward!

Edited 5/16/2009 5:42 am ET by Piffin

And we only frame a hip roof once every 8-10 years.>>>>>>>>>>>>..

That's it, I m moving to Maine!>G<

Seriously, it seems that every ach and designer has decided that hips are cool!

I much prefer to frame hips.

Not hard either way.<G<

8 hours for conventional.

6 hours for trusses if the truss manufacturers have their act together.

6 hrs to truss and brace with how many people?

two people, three hours.

Those are very small mono trusses.

Coupla variables in there.

Can your guy actually cut a Bastartd Hip? Or is it going to be an all day exercise in pulling lines and taking measurements?

Are you sure the local Gesta..............I mean building department will let you frame it 24 oc?

I assume you'll need a crane for the trusses. How ya gonna get the stick framing up there?

I'd guess 3 guys, 2 hours to set the trusses, but then how much time for all the backframing and finishing? I don't know. It's been too long for me.

I would guess 3 guys all day (9 hours) to stick it, including the joists. But Like I said, it's been a while.

Can your guy actually cut a Bastartd Hip? Or is it going to be an all day exercise in pulling lines and taking measurements?

Now that may be the salient point and the heart of the matter.

Suppose the plans don't have a good roof framing plan page? Suppose the elevations have an error, in that the drafter shows that pitch as a 6:12 in the view drawn? Suppose that there is nothing on paper to show that hip coming to the up corner?

Then, you're right, you can have most of a day wasted, fooling around with discussions, strings, try-pieces that don't work, etc.

View Image

"A stripe is just as real as a dadgummed flower."

Gene Davis 1920-1985

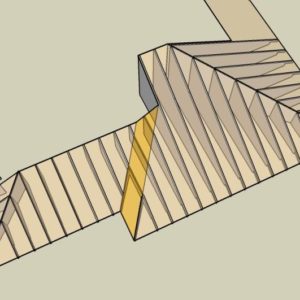

Sorry I don't have an answer for your question, but what is that drawn with? Softplan?Legal Disclaimer: The preceeding comments are for entertainment purposes only and are in no way to be construed as professional advice. The reader of these comments agrees to hold harmless the poster, EJCinc, from any and all claims that EJCinc offered professional advice, ideas, or comments to the reader that may or may not have resulted in the damage, injury, or death to the readers property or person.

Chief Architect for the whole project, Sketchup for the truss workout.

View Image

"A stripe is just as real as a dadgummed flower."

Gene Davis 1920-1985

My estimate was for the total roof.

"Suppose the plans don't have a good roof framing plan page? Suppose the elevations have an error, in that the drafter shows that pitch as a 6:12 in the view drawn? Suppose that there is nothing on paper to show that hip coming to the up corner?"

You are overthinking it again Gene.

The plans you posted are good enough and if you hadn't bothered to figure out that one section that had the different slope, any competent carpenter would have quickly figured it out. A simple +/- notation to warn about a variation on the slope would have been plenty enough for me.

A "good framing" plan to me advises me of which way the floor joist and ceiling joist will run and I've never hesitated to change THAT in the field when it made more sense.

My dad does large projects......multi family, Townhouse, Mid and Hi rise and assisted living.

The last time he had a project with a bastard hip.......a single family for an executive in the company.....his framing contractor (somewhere like 15 or so crews) didn't have a single guy who could cut it.

He probably didn't have anyone that could speak english either.

I'd hate to be a young man just getting started framing...

I always get a kick out of these threads about roof framing as we have no idea what it is here in Florida (at least in central and south Florida). I honestly have not seen a roof fully framed and not used trusses in maybe 10-12 years. I don't know a framer who could cut a simple hip as they would expect trusses to be used.

Kind of sad I know as it leaves the skill a dying art here.

I honestly have not seen a roof fully framed and not used trusses in maybe 10-12 years.

from 1980 on.............never framed a single roof in Florida that wasn't trusses.

Saw a few......mostly Suarez Bro's in that gated community off of Bears ave.

That Pulte Development, Quail ridge I think, between Gunn Hwy and Linebaugh Ave?

They used to drop us 2 houses of trusses a day.

Robert,

Agreed. Even one of the 10,000 sq ft homes I saw being completely framed in Avala a few years back had trusses set on it!

Kind of funny to see a huge two story house completey framed (as in not one concrete block which is the norm in this part of Florida) then to see it capped with trusses.

i would expect ALL 10,000 sf houses to be trussed be cause of the larger roof sizes (spans).

I could go on for hours about stick framing roofs on homes 10,000 sqft or larger.

In fact, I can't remember seeing a truss on a large custom home in the N.J.-P.A. area in some time.

Lots of tract homes, but not on a custom. I've cut and loaded trainloads of 2x10's and 2x12's onto lifts for roofs.

Probably why I have this big lump on my right shoulder.

It just goes to show you how different things are in different regions.

Most of the custom homes I've worked on had spans far too long for 2x10s or 2x12's or anything but trusses. The open concept hit MI back in my first years of my apprenticeship in the 70's and the open rooms have grown bigger and bigger every decade. It was not unsual to see 30 x 40 open rooms in large customs. Almost every garage I built had spans far too long for structural ridge beams or conventional rafters.

Of course, on those types of homes, a non skilled framer was not going to be able to decipher the complex roof systems even if it was trussed. I've mentioned this before but I had one house (about 3000 sf) with a roof system so complex that it took me a day and a half, on site, with the trusses and all the paperwork in hand, to study the package enough so that I understood it and could proceed.

In SE MI there was one area where the very cheapest Italian builders insisted on stickframing the roofs. I don't think they saved any money doing it that way. I think it was done for two reasons. 1) their plans were the same plans that they had tweaked from the 60's (the Italians all love the same style ranch home). 2) they didn't have to place an order for trusses a couple weeks in advance, which would put a dent in their cashflow. These builders would literally tweak their lumber lists down to the last stud. They had built that same house so many times that there was not one stick of lumber left when the house was done.

If we get back to this specific roof with its irregular hip and adjacent valley, and look at the pics I provided in earlier posts, you can see that the bastard hip condition is a necessary solution for the roof to hip to that nearby upper wall corner.

It does this to create an acceptable roof-to-wall condition upslope from that corner. Without the solution, all is total roof craziness around the corner and uphill.

Suppose the plans don't include a roof framing plan, nor do they show a roof plan. Suppose that they show roof lines dotted in on floor plans, and that those two intersects, the hip and its nextdoor valley, are shown as "regulars," i.e., their plan angles are 45 at the corners.

Suppose also that the most capable carp on the job, the lead guy, doesn't cut all that many roofs, and that he does all his workouts on the clock, never bothering to study the plans at home in evenings.

How much time do you think might get wasted on site, with the hourly clocks running, for him and his two helpers to come about to the right solution of irregular hip and valley, then cut everyting right, and get it stacked.

The pic attached shows the correct parts in place, and the inaccurate H & V lines that the floor plans and elevations show.

View Image

"A stripe is just as real as a dadgummed flower."

Gene Davis 1920-1985

I just want to know what the term "bastard hip" means.

My 2 cents is that I've built both stick built and trusses and have been on lots of roofs that others have built. Usually the saggy out of level roofs are stick built. Trusses use smaller members and with a couple of little tricks go up pretty quick.

Have a good day

Cliffy

Bastard hip or valley is where two differently pitched roofs meet.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Now I'm up to speed on the techno jargon!

Have a good day

CLiffy

My old brain is not elastic enough to play with all these ifs and supposes.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Gene, your question now is much different from the orginal post. You've interjected some very pertinent facts i.e., "Suppose that they show roof lines dotted in on floor plans, and that those two intersects, the hip and its nextdoor valley, are shown as "regulars,".

That constitutes a mistake on the plans if the dotted lines don't jive with the elevation view.

So, an unskilled group of roof framers could theoretically spend many hours, maybe a few days wrestling with that one corner if they didn't seek clarification. Some guys are so unsure of themselves that they might refuse to seek help because they think it will expose their lack of roof framing knowledge.

If I was given that set of plans, and didnt' need to do much studying before I built, and no note was given that there was a different pitch on that one section, I might be fooled as I started assembling the roof but I would quickly figure it out. I might get three or four parts (in that area) nailed up before I discovered the error. I might then spend fifteen or twenty minutes analyzing the situation. I might figure it out in two minutes. It's hard to say.

So, there is no real answer to your speculative question. I suspect that this is a real life problem and you are searching in here for backup for your position. Is some builder hitting you up for backcharges on design where you made this error?

Edited 5/18/2009 9:05 am ET by jimAKAblue

See why I answered as ambivalently as he wrote the Q?

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

I knew that.

I'm just willing to offer some hard numbers on a topic I'm very familiar with. Perhaps, the information will be helpful to others. Maybe not, maybe so. I just call them as I see them.

This was actually a relatively low span but large footprint.

That is the beauty of your skill with sketchup, the fact that you can do the layout and dimensions and create a cut list with the computer to save the guys in the field from the wasted effort and guessing/try pieces that don't work, etc.

Even if your calculations are off a little bit the crew will be able, from that starting point, to correct it.

Also as a working carpenter I would much rather build it stick frame, a lot more fun than trusses. Everything else being equal.

I have often thought it would be a good business plan to compete with the truss yards by offering a computer generated stick frame cut and stack roof. If you could deliver a precut bundle of lumber to the site that most carpenters could assemble I think the crew would love it.

If you could deliver a precut bundle of lumber to the site that most carpenters could assemble I think the crew would love it.

I wouldn't bet the farm on that idea.

1)Most carpenters* enjoy cutting roofs. They don't want a third party to do all the "fun" stuff and leave them with all the grunt work.

2) Often, it takes significant time, energy and frustration to sort through complex piles of pre-fabbed components.

3) Often, the prefabbed components are theoretically cut to perfect theoretical lines.

a) The actual lines aren't as precise as the theoretcal lines

b) The components strive to be perfect buy aren't

c) figuring out how to tweak the many possible combinations can be maddening

*The definition of Carpenter, for this discussion, is someone who has attained ALL the skills to build a house.

I beg to differ, regardless of your definition of carpenter, if I had a choice between framing a stick built roof from a precut set of rafters or setting trusses and the associated back framing I would choose the stick built frame.

What would you choose as a preferable day at work between the two?

When I cut a roof I make the cuts based on theoretical calculations (math) and am then faced with the same assembly "challenges" you outline in your post only I am slightly more invested in making it work since it was my theoretical calculation the cuts were based on.

The way I see it there are two challenges an experienced carpenter faces in cutting and stacking a roof. 1. calculating the cuts. 2. making the cuts work.

As you point out the actual lines aren't as precise as the theoretical ones.

"I beg to differ, regardless of your definition of carpenter, if I had a choice between framing a stick built roof from a precut set of rafters or setting trusses and the associated back framing I would choose the stick built frame. "

What is the "associated back framing" that you refer too?

On trusses, the only back framing that I can think of is the lateral bracing that is typically specified for on some compression webs. I trained my rookies to do that on their first truss experience and if they couldn't get it all done correctly in about ten minutes (longer on big customs), then there would be hell to pay.

Because I am a carpenter, I can say for certainty that I wouldn't want to farm out the cutting of the roof, only to have to go through the unenviable task of putting the tinker toy puzzle together. Trusses pose those same challenges but their designs normally allow for much easier adjustments when the inivitable "problem" surfaces.

Quite frankly, if I couldn't cut my own roof I'd be so ashamed that I'd strip my title of carpenter and label myself "wall banger" and go home and study till I could cut that roof without hesitation.

"Quite frankly, if I couldn't cut my own roof I'd be so ashamed that I'd strip my title of carpenter and label myself "wall banger" and go home and study till I could cut that roof without hesitation."Agreed - that is going in the famous BT quotes thread!

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

"When I cut a roof I make the cuts based on theoretical calculations (math) and am then faced with the same assembly "challenges" you outline in your post only I am slightly more invested in making it work since it was my theoretical calculation the cuts were based on."

The "slightly more invested" is precisely the reason why no self respecting "true" carpenter, would want someone off site cutting his roof package.

The on-site ability to tweak decisions during the cutting process is significant and cannot be overstated.

"if I had a choice between framing a stick built roof from a precut set of rafters or setting trusses and the associated back framing I would choose the stick built frame.

What would you choose as a preferable day at work between the two? "

Trusses by a long, long margin. I can't imagine any scenario where I would prefer the precut conventionally framed roof. Of course, this assumes that I can get my crane or skytrak in there...

one more - precuts are made by a machine crew so there is little or no crowning or eyeing the wood for knots to work around. Your worst lumber flaws can end up in the worst places. So you have to replace and recut some pieces.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

I don't have a total number of hours for you Gene but I can say almost any framer I know can set trusses but many cannot cut that roof well on the first try.

Unless you are really confident in your framer, I would go with the trusses.

Mike