Mudsill retrofit questions, and more

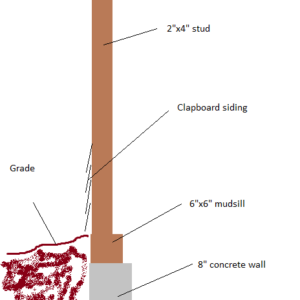

We have a detached garage that I use as a workshop. I’m guessing it’s about 80 years old. The problem should be clear from the picture: grade extends above the mudsill and all the wood below grade is in pretty much rotted. But, if I dig deep enough, there’s concrete under there! Grade must have come up at some point because the lower course of clapboard is in the dirt, too, and it’s mostly a memory at this time.

The cure seems pretty obvious: I’ll add some CMU to the top of the wall, probably two courses, and add a new mudsill. I have some specific questions.

1. How aggressively should I tie in my CMU into the concrete? This isn’t earthquake or hurricane country. I’m going to be doing this in sections, so I’m a little reluctant to be buying tubes of Simpson epoxy that will largely go to waste. I was thinking that, realistically, drilling in some dowels should be sufficient.

2. Anchor bolts will be in the way for inserting new mudsills. I could cut notches in the mudsills, or I could drill for expansion bolts (or epoxy and threaded rod) after the fact. Is there an actual engineering argument against notching the sills, or does that idea bug me for no reason?

3. What about sill gasket? As I fix it up, the building is slowly becoming better at keeping out the elements: until recently it wasn’t squirrel-proof and the place was filling up with walnuts. But anyway: I was going to cut the studs to a nice tight fit and then tap the sill in with a sledge hammer. That rules out using sill gasket off the roll. Should I just use some sorta caulking between the masonry and sill? Would it be worthwhile to go to pressure-treated material if I don’t use a sill gasket?

Thanks in advance guys!

Replies

I would not think of repairing rotten wood that is in contact with masonry with anything else but treated lumber, especially if you cant get sill seal or a like product under there.

YOur picture only tells a partial story. What's your floor system inside the garage?