Need help upgrading my homes insulation!

(Sorry for the long read)

Hello! We are currently renovating our home that was built in 1996 and we are located in climate zone 5 (western new york). It has come time to tackle insulation. The house is always a little chilly and we are aware that there was a rodent problem in the past that has since been delt with by us. Previous owners didnt take the best care of things….

The old insulation setup was yellow fiberglass batts with a poly/plastic vapor barrier then drywall on top. I was never a fan of this approach as there is always a chance the poly/plastic vapor barrier will get punctured by nails (pictures, shelf’s, etc). So I’m trying to find a good way to upgrade the homes insulation while also preventing condensation in the stud bays. Now that the walls are opened up, this is my chance to better insulate this home. Exterior insulation isn’t an option. We also didn’t plan on using spray foam.

I have been doing research for 2+ months now and still haven’t gotten a solid answer regarding what’s best for my climate zone. I was debating installing 2” of XPS ridged foam board in each stud bay, then installing unfaced rockwool batts behind that then drywalling. In my climate zone, 2” of closed cell foam quality’s as a thermal break so I figured I don’t need a plastic vapor sheet before the drywall. I plan to seal all the joints around the ridged foam board before I install the batts to prevent warm air from coming in contact with cold air. I understand there will still be some thermal bridging with the studs, but isn’t that how all homes are? There’s no way to add a thermal break for the studs without either exterior insulation or expensive T-Studs.

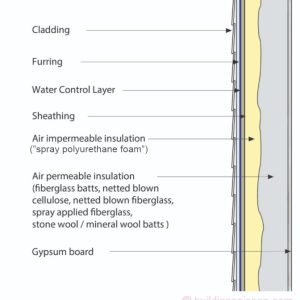

Useful article: https://buildingscience.com/documents/building-science-insights-newsletters/bsi-116-interior-spray-foam (I was thinking instead of spray foam, I could just use 2” ridged board foam). Same outcome as the image picture below, just not with spray foam.

All I know is that I want better insulation for my house while also preventing condensation from forming inside the stud bay and rotting out my wood and causing mold. I’m open to ideas and suggestions. I really need help here. Thank you.

Replies

You can install rock wool to fill the stud cavities, and then place a layer of rigid foam board across the studs to add more insulation and provide a thermal break. Run the boards horizontal to the floor and stagger the joints. Carefully tape the joints as well, and use a combination of pro spray foam, tape or sealant to adhere the foam to the floor, base plate of the wall, and at the top to the top plate and ceiling.

Pay attention to properly insulate the rim joist of the floor and above if you have a second floor.

There is nothing wrong with a sheet plastic interior vapor barrier if care is taken during installation and when putting up the drywall.

sealing penetrations for electric and plumbing is important.

Adding a layer of sheet foam between the studs and drywall will be a lot simpler and more effective than trying to piece things between studs.

You will want to use drywall screws a bit longer to account for the foam thickness, and you would be well advised to measure and mark stud locations so you can find them from the drywall finish side without error.

Thank you for taking the time to respond. My only issue with adding the foam board before the drywall is that it needs to be at 2” thick in my zone then drywall on top of that which will eat into more living space. The house is already framed with 2x6 so I have plenty of cavity to fill.

If you put the foam on the inside (heated) side of the fiber insulation, it does not need to be so thick. you can use an inch or even half inch to provide the thermal break. If you like, you could even cut the foam sheet into strips to use as spacers between the studs and drywall. (but you would need a separate vapor control layer) Paint rated for this use could do)

The reason for thick insulation against the other side of the wall assy is to raise the temperature of the vapor interface above the expected dew point. With the foam on the inside the face will be closer to interior temp,, and should be well above the dew point.

You also could provide some thermal isolation by using horizontal strapping between the stud face and the drywall. Spacing 3 inch wide strapping at 24 inch centers would mean the drywall to stud contact area would be reduced by 8 times.

You can use 3/4 strapping or metal hat strap, (which is a little thicker).

This might also be attractive if your studs are less than straight along the wall, and let you shim to get a more even surface for the drywall.

You would want to provide fire stop every ten feet along the wall if your choice includes an open air gap.

Here’s an alternative that developed (at least here on the forum) a while ago.

I know several of the builders well and they wouldn’t bs you.

It does involve reducing your interior dimensions by a few inches.

Take a look.

https://www.finehomebuilding.com/?s=Search%20for%20Mooney%20wall&es%5Bpost_type%5D%5Band%5D%5B0%5D=forum&referer=

I have actually seen this system before on here while doing research. I’d really like to maintain as much living space as possible. I already have 2x6 framing.

Great job on tackling your home renovation! Your plan for 2” XPS rigid foam board and unfaced rockwool batts seems solid. Good call on addressing condensation concerns. Consider consulting a local insulation professional for personalized advice. Best of luck with your project!

Pat,

I went through a similar exercise a few months back while remodeling a kitchen in my 120 year old house in zone 5 (Wisconsin). The most useful tool for me in finally deciding on an insulation strategy was to perform some basic U-factor calculations for my potential wall assemblies, including cavity, framing, and window areas. There's plenty of information on this topic over at GBA, including this article:

https://www.greenbuildingadvisor.com/article/all-about-u-factor

In the end a Bonfig Wall assembly was the best option for me (starting with a 2x4 wall and furred out to a final 2x6 depth with an added thermal break) as I needed to flatten my walls anyway and could afford the loss of 1.5" of space.

Good luck and let us know what you decide.