No-fascia knife-edge roof detail. How to best do it?

Over in the excellent forum “Contractor Talk,” a builder shows photos of an elegantly-designed and meticulously-executed house he is doing for a client, somewhere on Massachusett’s SE coastline. On it, the architect has featured knife-edged roof details everywhere.

There are roofs with pitches from as low as 3:12 up to 12:12 terminating with the roofing-meets-soffit detail, and even one over a turrent, with a circular edge.

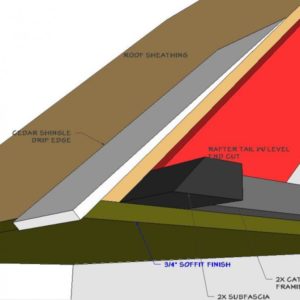

The detail used to build, and done per the architect, is pretty well replicated in my sketch shown here, the one with the wood shingle starter.

Note how the outboard edge of the soffit finish is beveled, with its knife edge right under the outer edge. I show a “starter strip” of wood shingle, but in fact the builder ran lineals of wood clapboard siding along there, fat edge down just like my shingle, and the same purpose was served. That purpose was to have a means of better “stitching” the edge, so that the soffit edge was well-fixed to the knifepoint. In the photos shown at the CT forum, one can see the edge of that clap, under the roofing, above the outer edge of the soffit finish.

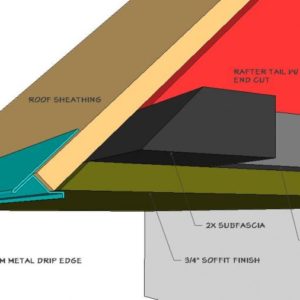

My alternate design, the one I dreamed up for this which may or may not be an improvement, is also shown, and I used a custom metal drip edge.

The drip edge’s bottom leg “returns” so as to lap and slightly “capture” the edge of the soffit finish. Before the drip is tacked on, the same kind of edge “stitching” is done, in the form of screws at maybe 8″ centers, down through the sheathing and into the soffit edge, to keep things tight, hopefully.

Your comments are indeed welcome.

Replies

I'm shocked!

Truly shocked, that there are no responses to this roof edge question! ;-)

In the good old days of Breaktime B.C., a simple question of "to use metal drip edge or not to use metal drip edge" would have gotten pages and pages of chatter.

I guess we're all too busy working, to reply.

Or maybe it is because there are so few "we" left?

Okay I'll bite.

FWIW, I have never done a knife edge soffit treatment - I have seen them, and on the right roofline situation, are an eye catching detail.

I do feel your custom drip edge is an improvement. My only change I would make is to have the return leg a bit longer to cover more of the soffit-to-sheathing joint in the event that shrinkage or other movement occurs.

With the caveat that the drip edge color and soffit color are the same or complimentary.

Terry

Another couple sketches to better describe my proposal.

Attached.

One shows how 1-1/2" screws at about 6" centers are used to "stitch" the deck sheathing edge to the bevel-ripped outermost soffit plank. Soffit finish is linear t&g beve-edge 1x4 cedar, painted.

The other shows a section view, and a better version, we hope, of the custom metal drip edge.

The photo is one clipped from the Contractor Talk thread where this was first seen by me. Credits to the builder, Cornerstone Construction, of Acushnet, MA. In the photo you can see the edge of the beveled clapboard that was used as the "edge tie" for the arrangement. Refer to the images in my opening post, one of which shows this as-built detail.

Interesting detail...

A wider shot would be nice, like of the whole house.

Looks 'spensive, too... and your stiching thing, looks... like, well... very ingineared. I wouldn't. The joint is covered by a custom drip edge that's going to run costs up more than a little bit. Siders are going to want more for the stich, too. Let them the leave a gap. Cork it.

Once again, credits to Cornerstone Construction, Acushnet, MA

Pics shown below all from house designed and built with knife-edged eaves everywhere.

As can be seen, pitches vary from quite shallow on the cupola, to steep for the main pitch. Note the circular turrets, and also one that is segmented.

While the curved eaves do not show the telltale wood edge between soffit edge and shingles, all the straight eaves were done using the clapboard lineal along the edge.

In the one pic that shows an in-progress eave, you can see how the deck sheathing is brought short of the underlipping soffit finish. In other words, the deck comes short, while the soffit finish runs out to the knife edge. Look at the bevel. The builder's next step is to place an 8" clapboard along the roof edge, fat edge down at roof edge, and stitch screw on close centers, two rows, one row into the soffit finish, the upper row into the sheathing. That clap serves one purpose only, and that is as a "stitching tie."

The builder commented to a post of mine in which I asked about the detail, and said that the framing and finish work for these knife-edge eaves was very demanding, requiring a much higher degree of fit, line, and finish accuracy than a roof edge would normally have.

Does that constitute inginearing? I don't know. All I know is that, having only once built without a drip edge, and substituting an undercourse starter thing of cedar shingles, that I did not really trust it to last. I like the look of the no-fascia knife, but am seeking to improve upon the detail.

The builder also said, when it came to the curved eaves of the turret roofs, he could not do the straight clapboard overlay thing, so instead used wood shingles to work his way around the curves. I don't have an answer as to why you can see the edge of the wood clap in the one photo, but cannot see the ends of the wood shingles in the photo showing the round edge.

Probably the camera angle is not right to be able to see the wood between shingle and soffit, at that curved-roof closeup.

He commented that on the lowest pitches, such as at the cupola, he first reinforced the OSB-soffit joint by bridging it with copper sheet strip, screwing through into both OSB and soffit, then went next with the clap thing, then roofing.

I think the architects up along the NE coastline, from the Hamptons, up through Montauk, then over from New London all the way up to the end of Maine, have got themselves into a knife-edge fight. Go to the web page of Eck/McNeely Architects, in which is a link to a very large portfolio of work, and you'll see knives everywhere. It's a fad.

Resurrecting this old post

I would really like to do a knife edge on my current project and was wondering if there are any more ideas/ comments out there?

I'm currently working on a project that intends to incorporate the knife edge with a soffit that mirrors the roof angle to conceal R.C beams below the roof. I wonder hot to execute this while use corrugated roof tiles nailed to battens. I'll share my details once I confidently execute something that I think may work.