Old customer called – needed a 12′ high (!) mushroom for his kid to play in, to match his really well-done Hobbet hole (curved concrete walls (like a banana), turf roof, dug into a bank, round door and windows).

His goal is to do it in a thrash the week before Christmas, while the wife and kid precede him to the inlaws.

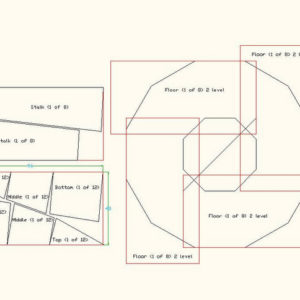

My goal is to design it entirely as a skin-loaded structure with a lot of precisely cut repetitive elements – minimal ribs in the cap, just enough to catch screws at each joint – like maybe a beveled 2×3. Skin will be carefully beveled 1/2″ (untreated) 4-ply BC plywood.

The stem will have 2x4s at the joints, extending down into gravel-filled holes a couple of feet.

Hollow tapered octagonal stem; little door, ladder up into cap – cap floor level is ~6’8″. 11′ foot diameter dodecagonal cap will have dormer(s) of some type. Cap floor will be a torsion box of 1×4 webbing skinned with ply on both sides into a light, thin donut.

Cap will be covered in some scrap fiberglas mat and extra Seal-O-Flex, acting as all-encompassing “skin”. Probably painted tomato red with white polka-dots.

Been laying it out and sizing it to make good use of the plywood – should be (18) sheets, with the scrap making a dormer or two.

Forrest – trying to weird this place up again

Edited 12/3/2008 6:00 am ET by McDesign

Replies

Looks like a combination pain the rear and fun one to build.

On your cut sheets ... the 2 on the left I understand, but the 4 on the right look like the sheets of ply overlap.

"Put your creed in your deed." Emerson

"When asked if you can do something, tell'em "Why certainly I can", then get busy and find a way to do it." T. Roosevelt

Yer right - since that drawing I've slid each full piece back, or out, about 7" on its long axis.

Forrest

"Mushroom by Tiffany"? :)

Looks like a fun job.

Have you considered 1/2 mdo for this instead of cdx?

I've not used MDO - how is it for crumbling near the edge? Would I have to pre-drill and c-sink each screw hole?

Forrest

No, he said MDO, not MDF. MDO is fir Ply with craft facing.

Cool project, but by Xmas? get crack-a-lackin.Spheramid Enterprises Architectural Woodworks

Repairs, Remodeling, Restorations

They kill Prophets, for Profits.

I said MDO also - I've used MDF, but it's weak near the edge. I want to use flat underhead (Kreg type) pan-head screws in csk holes just deep enough to bondo the hole flat afterward.

Forrest

MDO should work well for that and the surface is perfect for paint.

Sorry, maybe I wasn't clear , lack of coffee, and little sleep.

The MDO doesn't have those issues of MDF, being as it is alternate plies of Doug.Fir. Like any ply wood, it is possible to have an edge chunk wiggle out, but not near the fractures that MDF can have...or worse Particle board, which is HDF as far as I was taught.Spheramid Enterprises Architectural Woodworks

Repairs, Remodeling, Restorations

They kill Prophets, for Profits.

You must be a fungii to work with.

LOL! Will pass that on.

Forrest

I wouldn't do such a nice neat job of the form. I'd goober it together in an afternoon pour plaster over it and then use that to make a mold. Over the mold I'd lay about six layers of matt fiberglass, let it dry overnight and start painting.. The Fiberglas will be nice and rolly to better simulate a real mushroom.. If the form it's made on crumbles so what? The Fiberglas skin is what's important..

Probably could do it with a roll of matt and 10 gallons of resin..

Edited 12/3/2008 11:58 am ET by frenchy

Yeah, but it wouldn't be cute carpentry!

Forrest

I've actually come up with an even simpler and faster way if you're interested..

what? no walnut & shellac?

;)

If ya start with a goober then you'll end up with a goober.

He wants a mushroom, not a peanut.

I've done a lot of fiberglas work.. I know time spent making the mold is wasted when only one or two are needed. In the trade they are called spalsh molds and not known for their quality of construction. Bondo is used as a glue and chicken wire plays a very important piece..

Nail guns and sheet rock screws are considered quality tools.. even if they come from harbor freight..

The molds I made for my car trailers were designed to make a 100 copies and I made them in a single day.. ( I still have them 20 years later) I've still got splash molds for all my race cars.. plus a few other toys..

The stem reminded me of a project I did a while back.

I don't think my method would help , but I think it's interesting.

Sorry about the size! Could some kind soul resize them for this

(mostly lazy, but in my own defence I am an idiot) carpenter?

It was a sculptural form, that the client painted to look like two Styrofoam cups (whatever they want right).

I already had my homemade "clamping Jig" so I made it without internal supports to help meet the weight requirements.

You get kicked out of that nice cushy office job already?

Family.....They're always there when they need you.

Nah - just looking for a side job to keep up my street cred here, for the nineteen people still around!

Forrest

I am watching with avid interest. This looks like a cool one. Just like all the others....=)Naive but refreshing !

Man, and you get paid for this??? Looks like a fun project. Keep us updated! =)

See my work at TedsCarpentry.com

Buy Cheap Tools! BuildersTools.net

If you haven't already done so, please update your profile. Since many issues are dependant on the region in which you work, we often look at your profile to see where you are writing from.