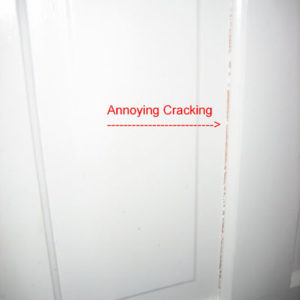

Any tips on painting a panel door to minimize the cracking as the door shifts with changes in humidity, etc? I’ve attached a picture to show what I’m talking about.

Discussion Forum

Discussion Forum

Up Next

Video Shorts

Featured Story

Tips for picking the right paintbrush based on paint type, surface, and personal comfort.

Highlights

"I have learned so much thanks to the searchable articles on the FHB website. I can confidently say that I expect to be a life-long subscriber." - M.K.

Fine Homebuilding Magazine

- Home Group

- Antique Trader

- Arts & Crafts Homes

- Bank Note Reporter

- Cabin Life

- Cuisine at Home

- Fine Gardening

- Fine Woodworking

- Green Building Advisor

- Garden Gate

- Horticulture

- Keep Craft Alive

- Log Home Living

- Military Trader/Vehicles

- Numismatic News

- Numismaster

- Old Cars Weekly

- Old House Journal

- Period Homes

- Popular Woodworking

- Script

- ShopNotes

- Sports Collectors Digest

- Threads

- Timber Home Living

- Traditional Building

- Woodsmith

- World Coin News

- Writer's Digest

Replies

When I order doors that will be painted, I have them factory primed prior to assembly.

Obviously, its too late for that in this instance. Your best bet now, before the heating season comes to a close and the humidity inside the home begins to creep up, is to sand the paint edge around each of the panels. Prime the currently exposed portions and then give the panels a fresh coat of paint.

I can't guarentee it won't re-occur, but it should help minimize the shrinking/swelling creating the cracks, or at least hide the effects.

If you find it doesn't help enough this go round, scrape out the paint joint between panels and framework before caulking with a good (flexible), latex caulk, and then repaint.

If its happening throughout the house to a good degree, you may need to consider a humidifier.

J. D. Reynolds

Home Improvements

In the "more than you wanted to know department" : the paint cracks because the panels shrink between the time they were painted and when they show a crack. They shrink as a response to decreased humidity in their environment from when/where they were painted.

When manufactured, the doors are made from kiln dried (6-8% hardwoods, 9-11% softwoods) lumber, and this is as "pre-shrunk" as they should ever be. From the point of manufacture to the point of painting, the doors were exposed to increased humidity for some time - storage, jobsite, transport, etc. and this caused the panels to expand. You then painted them and then they again responded to a change in the humidity and contracted. The paint will not stop this moisture exchange, but it will slow it down a bit.

If you clean the paint line and repaint at a low ebb of the humidity cycle, then your problem should be mitigated. Once they are in a stable environment, they will reach the EMC for your area. Even exterior doors will reach a sort of EMC range of balance.

Dave S

http://www.acornwoodworks.com

acornw etal, You can have teh same problem with stained doors and if so I would assume the problem would be even harder to fix.

If you are going to stain panel doors what would you recommend?

I would think that you should attempt to finish them in a very very dry environment so that the only movement would be in expansion thus not exposing unfinished material in the future as mositure increases. ??????

If so, how?

It is not a good idea to force doors to a certain EMC by manipulating environment. When the doors are made, they will be at the lowest end of the humidity cycle, and that is the time to finish - stain or paint. If the doors are locally made and you have access to them shortly after fabrication, that is best.

If you use factory doors coming from a time zone or three away, the doors may languish in storage of questionable integrity and start to swell the panels. Then you'll get them, finish, and then they will shrink and..... Just one of the drawbacks of centralized door production facilities.

As one previous poster said, you can have the panels pre primed and pre finished to alleviate the problem. We produce doors every day, and have never seen the problem, but we either finish the doors ourselves - or ship doors to the painter so they can finish right away. every commercial manufacturer of doors has a warranty that includes a short time between receipt of doors and finishing, as well as recommendations on storage environments. The warranties are, of course, designed to reduce warranty claims by exclusion.

Dave S

Thanks for the info. The doors could actually be the originals (circa 1892). We had them dipped & stripped last year, then let them be for a few months in the house before we painted late last summer. The doors seemed dry, but I never checked the MC. Used Zinnser water-based primer and Benjamin Moore latex (good stuff, just forgot the name) I think I may try sanding down the joints now when they are exposed and priming/painting again.

Did you paint the top and bottom of the door?

splat

We had them dipped & stripped last year, then let them be for a few months in the house before we painted late last summer.

Ouch!.....and therein lies your problem. Probably to toughest time of year to apply a finish to any wood product.

I actually avoid scheduling hardwood floor installations from late July through early September. Not that it can't be done...just not the best time to do so.

Git on those doors before the humidity begins to rise!

J. D. Reynolds

Home Improvements

What is it Homer Simpson say....Doooaah!!!

Guess the four we have out at the strip-it shop now will either hang for the next 10 months unpainted so we can paint them in winter '07, or hope they come dry enough from the stripper to paint immediately.

Don't most builders buy stock doors and therefore don't get them at teh dry end of teh spectrum? It would be nice to buy locally and finish immediately, but I would think that teh exception rather than the rule.

should have gone with solid MDF, the wood doors you have now will be problematic for years.

MDF doors are like $3.00 hammers and $14.00 cordless drills. The absolute cheapest thing that is still recognizable as what it is being sold for. This same thing will barely perform the function you paid for, but you did save money, which is really the goal, after all. This consumerist attitude makes point of sale far more important than longevity, environmental impact or economic logic. By by god, you saved a few bucks, and the greeters smiled as you drug the doors out of the big box.

MDF doors fail at a much higher rate than any solid wood door, and when they fail - typically by cracking across the width at the bore in the free stile - they fail catastrophically and are unusable immediately. If a wood door cracks a little paint it is still 100% serviceable, for centuries even. The rush rush of modern paced U.S. construction ignores such formerly time-honored details as acclimatization and general knowledge about wood's properties in favor of "expediency." Problematic for years - give me a break! It is simple science, not voodoo.

If the item doesn't perform as anticipated, then it is because it is wood - that mysterious material that supposedly grows on trees. Better to buy plastic, metal or goo goo wood. When it is the lack of understanding of the buyer, contractor, installer or whomever that causes the problem, but the wood door gets the blame. And the marketers of MDF doors are right there, ready to console you with their disposable products. We would all say the same thing about cardiac stents were they available at Home Depot - darn things are hard to work, and are too daggone complicated.

Go to any Architectural salvage yard and ask for MDF, fiberglass or metal doors. Tell 'em you got a $3.00 hammer and you are ready to put up a door.

I am at a complete loss (as my cynicism shows) as to why people that supposedly are in the know are so quick to drop a world-wide, centuries old preferred material and substitute what can at best be a temporary, disposable material that does nothing to enhance the quality of life, economy or craft. What am I missing here?

Dave S

Well said Acorn, as I am about to tung oil 12 5-panel fir doors. I never understood why one would want to paint woodwork anyway, since MDF is not rally woodwork, that I can understand.

A painter friend told me the best approach is to sand down the paint crack and then use a small artist type brush to touch up the area. Use as little paint as possible or even thin it a bit. That way the paint doesn't "glue" the panel to the stiles/rails and allows the panel to move freely. This diminishes the likelyhood of a new paint crack forming.