I’m getting closer to actual construction of this Cedar pergola, thanks to the forums responses.

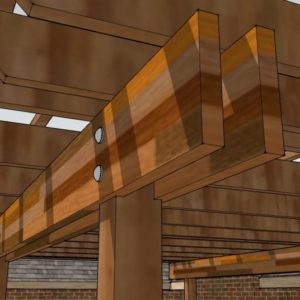

Attached is the latest design image.

My questions are:

1) Post Notching: Do I really need to notch the 6×6 post 1″ on each side so the 2×12 (or possiblily 2×10) Beams have a resting spot? My thoughts are the load from the 2×8 joist (or possibily 2×6) and rafters above the beam are that heavy compared to a fully covered roof. And I’m thinking by notching the post, this leaves an area where moisture can reside which may lead to premature wood rotting. Your thoughts?

2) Beam Size: I’ve shown 2×12 beams on each side of the post, but thinking 2×10’s would be sufficient, again as the load above is rather light. The distance between each post is 11’. I’ve even had some recommendations that 2×8 beams would be sufficient for an open Pergola such as this. What is the reccomended beam size for 11’ span between post for an open Pergola style such as this, using cedar?

Replies

I like your thinking

I like the way you're thinking on the detail. I won't speak to your structural aspects of your spans because that is something you should work out with a qualified engineer, but I can give you some advice on question #1.

It probably won't matter too much in terms of the longevity of your open air pergola, but if you want to maximize the life of any wood outdoors, you need keep two things in mind:

1. protect wood fibers from wicking miosture; particularly end grain where it is absorbed most readily.

2. shed water as best you can and allow wood to dry.

There are a myriad of ways and opinions on how to do this. It depends on how passionate you are (and how much time & money you have) for waging war against the natural elements.

I have constructed some clear western red cedar pergolas with some similar details. I had to attach some beams with no visible hangers which presented the problem of capping shallow mortises for bolts and still maintain structural integrity. Some mentioned that's hard to do; and they're right. Here's one way to handle it.

I also notched my 6x6 posts 3/4" to accept part of the beam. I used Smith clear epoxy sealer on all end grain and Eterna Bond taped the end grain of posts. If I had the time and inclination to do it again, I just thought of some additional details I might incorporate: sloping cut details in sketch included here. Tie slope cuts would still bear some of the wieght of the beams.(bolts would work harder with additional thrust; but they can handle it if designed properly) and if they were cut at a 15-20 degree angle will allow shedding of bulk water ( particularly with epoxied end grain sealed). However, those slope cuts add complexity to the assembly and additional cost ot my customer; but you may not have those restrictions. One has to guage their approach accordingly.

1. Post notching: The loads from this non-roof are really pretty minor so simply through bolting is probably OK. (I say probably because I've not done any calculations, nor will I do calcs. This is an educated guess based on many years as an engineer and builder of stuff.) But, I would cut the notches because it makes the structure look better... gives it some visually structural integrity. I wouldn't worry about the wetting of the end grain. The top of the post is also exposed. You could minimize this by adding a bit of peel & stick to the notch. The top of the post could receive a copper cap.

2. Any of the beam sizes you mention are going to be adequate to keep the structure from falling down. I think you could use all 2x4's and it would not fall down. It'd sag like crazy though. I would size the members for their visual integrity... make it look good. That means having proper size relationships among all the structural members. This is totally a subjective thing. You get to decide.

3. Joist size: see #2

Not asked this time: You are still showing the scarf as running the wrong way. What you show will probably still work since its all gravity loads and these are supported by the notches and bolts. But you might as well not slope the cut because this adds nothing. Do a simple half lap thing. That is, make the longitudinal cut horizontal, not sloped.

I don't find anything wrong with the proposed scarf joint for this project. You've provided bearing for both timbers (wave type moments are not an issue here) and given nice structural continuity to the beam members (particularly if glued up).

If you are going to make the scarf joint and glue it (cedar epoxies nicely-but clean wood with acetone) the tranditional lenght of the scarf is commonly recommended to be 8-12 x's the thickness. So for a 2x beam, that would be about 15-16" long. Your's appear shorter than this. I would also counter bore and lag together at the thinner ends during glue up...then plug it.

My point is... If we're going to call the joint he drew a scarf, then the thickness must be taken to be 11.25" (for a 2x12). Then at 8 to 12 times the thickness his scarf length would be 90 to 135". This would be, of course, crazy to do. If the scarf isn't done in this manner (this length) then there will be way too much end grain in the joint and the glue would fail. Even an epoxy joint would not be structurally sound.

The reality is that a scarf isn't needed since there is a support post at the joint. This post will take all the load thus making "nice structural continuity" (whatever that is) unnecessary. The other reality is that this is a pergola not a roof. The weight/loading is chump change. One could use nails to keep it all together.

But the knee braces are needed, assuming any sort of wind exposure.

Presumptive ignorance

Of course there is wind exposure. Do you know of anywhere we live that there isn't? You don't know whether the knee braces are needed or not. That is presumptive ignorance. The O.P. hasn't discussed the post connection to the ground. It could be the moment involved with the post connection to the ground (as a cantilever) is sufficient w/o knee braces. There are also (apparently) built in benches. These can create an opportunity to introduce a structural moment connection between the post, bench, and deck surface that can also additionally brace the cantilever.

Knee braces are not necessarily needed and they would fundamentally change the visual presence of the structure.* However the OP ought to consider lateral bracing of some sort.

Here's my definition

By strucural continuity I am mean that, with a properly constructed scarf joint, the beam can be act as continuous structural section in a multi-span condition (vs. simple span). This would introduce negative moments in the beam over the posts and assist with limiting deflection. BTW, deflection will exist whether we load the beam with a roof; or not. The OP talked about not being settled on 2x12's, but rather 2x10's or 2x8's. In that case the structural continuity would help achieve structural effeciency to a greater degree. Perhaps 8-12 x's the thickness (meaning 1.5") is not the correct rule of thumb for the scarf length, but eight or so feet is not it either. Hopefully someone more knowledgable on this type of joinery can weigh in on what a correct rule of thumb is for thickness and width of certain lumber sections (like 2x12 or 2x10's).

To your point on when a scarf joint is needed or not: Of course the posts will take "all the load". What else would carry them to the ground? The family pet? Anyhow, that is beside the point of choosing whether to use a scarf joint or a broken butt joint. Iit the fabricator's choice. I happen to think there are legitimater reasons to utilitze it...and have pointed them out.

Also, we don't always have to limit ourselves to building detail that just "keep(s) it all together". Sometimes there is value (to some folks) in expressing elegant joinery, a recognition of weathering elements, and balance in architecture. I recognize that you may not get that value.

Knee braces

You need to consider adding knee braces. This could easily rack.

New Pergola Design

After lots of research, the design has changed.

The beams are now 2x8's, running perpendicular from the house. The span between the post with the double 2x8 beams are longer (13') than the other direction (11'), so figure the larger boards should span the longer distance.

The joists are still 2x6 and now spanning the shorter distance of 11'. Separate 2x6 boards meet at the center post, butted together. Those meeting at the post are bolted thru the 6x6 post. This forms some support to racking, but I do plan on adding knee braces (not shown yet).

All 6 posts are attached to concrete using Simpson ABA66RZ metal post bases.

Appreciate any feedback on this latest Pergola design.

Hi Jak2, did you end up building this? If so, could you share some pictures of how it came out? I am working out similar design issues for mine, which is 12'x20' compared to your 13'x22', and I would love to hear what you think you got right or would do differently after finishing yours.

Thanks