Permanent Wood Foundations for Attached Garage

I have looked at some of the PWF guides on how to construct them, but for an attached garage the Diagram/figure that is shown for an attached garage raises some questions.

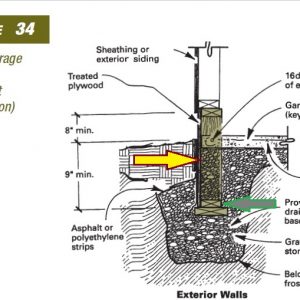

The attached file is of Figure 34 shows the design for the exterior walls of the attached garage. There are two arrows I have drawn on the figure. What is the material that is to be used pointed by the Yellow/Red Arrow? And how are the footplates underneath this material (pointed by the Gray/Green arrow) connected to this material?

Thanks.

Ken L

Replies

I have ask why a wood foundation? You obviously have vehicle access so transporting concrete is not an issue. Wood is not permanent.

First PWF is far cheaper than concrete. (both in actual cost and construction). Second PWF's have been used since the 1980s, including in the town I am in (including ones with full basements) and they are still standing.

Ken L

Wow! A foundation that lasts 40 years and is still standing.

Also concrete is an environmental catastrophe. There are better alternatives.

https://www.theguardian.com/cities/2019/feb/25/concrete-the-most-destructive-material-on-earth

And the preservatives from the pressure treated lumber leaching into the ground water is better? There are trade offs everywhere.

Good practice includes polyethylene on the outside of the "foundation wall." Modern preservatives (e.g., Micronized Copper Azole- MCA) are relatively innocuous and leaching is minimal in reasonably dry, stable soils But you're right, there are always trade-offs. Life's like that.

risks seem a little asymmetrical with your example

personally I'd use helical piers

I found your illustration in https://www.hillspg.compdfsPerm%20Wood%20Foundation.pdf, Fig 34, page 33. The image shows the equivalent of concrete footings and foundation walls, with the structure walls above, using the top plate of the "foundation wall" as a mud sill equivalent. Your red/yellow arrow points to the sheathing of the "foundation wall," which is ground contact treated plywood. It's important that the buried edge of the plywood be a factory edge, since that edge receives the full benefit of the pressure treatment. Any cut edges should be above ground level and very well treated with brush-on preservative.

The plywood is typically attached to the bottom plate with nails (Gray/Green arrow) which should at least be hot dip galvanized, but preferably stainless steel. There may be suitably corrosion resistant screws available, but nails are sufficient. Hardware specs are on P12 of the PWF spec.

There are several advantages to PWFs. They can be built by a skilled carpenter, so they may eliminate scheduling another trade, although the excavation, grading and compaction skills required are more common in the concrete trade. The compacted gravel under the "foundation wall" has to be dead flat and level.

Cement manufacturing is responsible for a significant portion of CO2 emission worldwide- I've seen a figure of 8%. A PWF foundation eliminates a lot of cement and is somewhat of a CO2 sink

Hello..

I'm looking for a detail as to what to do at the entrance for the cars. I'm guessing that you stop and terminate the PWF stemwall at each of the two car door openings, but I haven't seen anything that details that. The PWF is a system, not just a construct, so I was curious so that I do it correctly.

Please, no comments about why I shouldn't use wood.

Thank you!

Brian

This is the correct link to Permanent Wood Foundations - Design and Construction Guide:

https://hillspg.com/pdfs/Perm%20Wood%20Foundation.pdf

Thanks