plywood box for a choreographer

back from sea just a couple weeks now. Friend who is a choreographer asked for help making some plywood boxes for a show he is writing/producing.

the boxes need to be strong enough to support a dancer hopping around on them, yet disassemble for storage and transport. Any ideas on how to construct them?

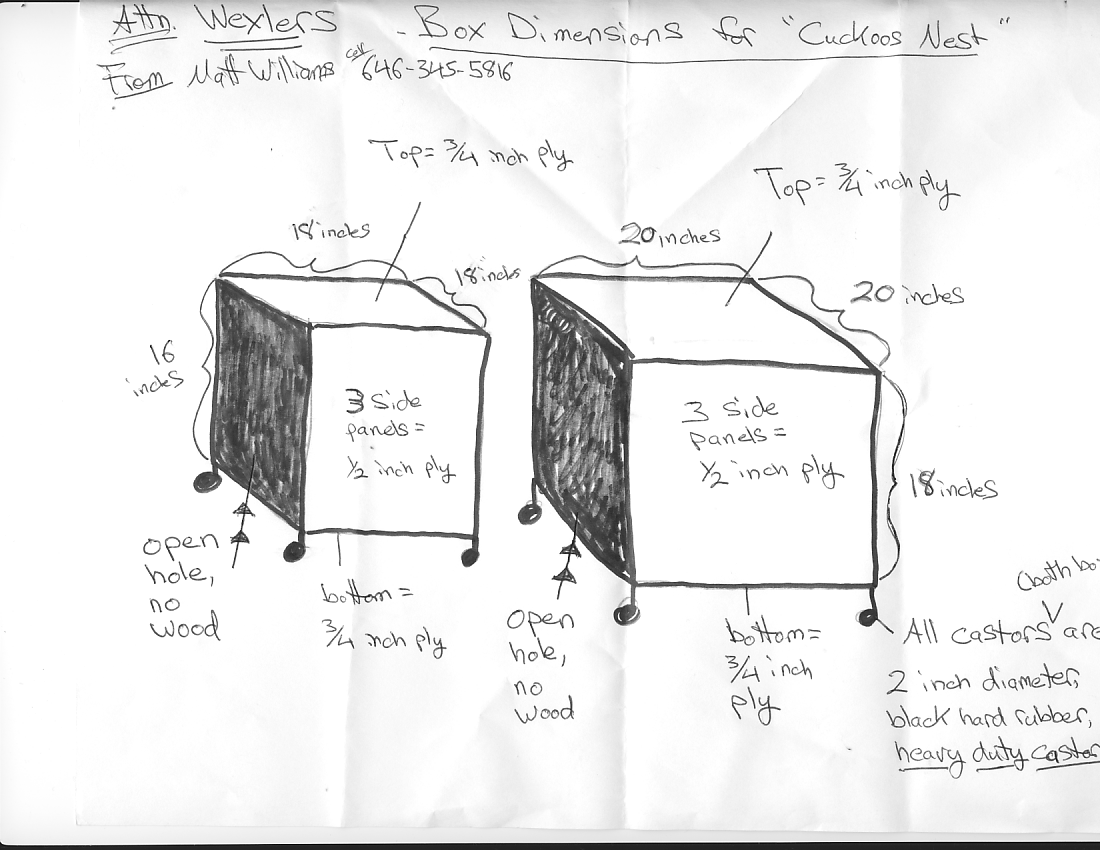

I’ve enclosed the sketch he gave me. He’s also thinking maybe instead of having one side open, as in the picture, to have a lid that opens so the dancer can pull out a prop. Even better would be a lid the opens and rotates, like the lcd screen on a handycam.

Much thanks.

Marine Engineer

Replies

I suppose the boxes could be built with blocking fastened permanently to each long side, around it's inside perimeter. Then drill holes in the ends/top/bottom, through the blocking, for a minimum number of removeable carriage bolts.

I suspect that any caster of that size won't give a big enough contact patch to keep the box from moving when a dancer jumps up on it. Instead I'd try to sell him on round rubber feet and some hand holds cut in the ends of the boxes, for two people to carry them,

Edited 4/6/2008 11:40 am by Hudson Valley Carpenter

Couple things came to my mind:

One--there are casters that are spring-loaded and sort of collapse when weight is applied--they are used on what I call "kick-stools" that are truncated metal cones and you kick them to roll them to where you need and when you stand on them, they sink to the floor--the edges of the bottom have rubber to prevent slipping. That might work for the casters.

Two--Leaving an open side would make them less strong--your idea of lid that flips up is better.

Three--how about nesting them for transport insteed of disassembly?

Four--I am a big fan of torsion box construction. This would make an especially strong platform for the "lid" of the box. Glue something like 1-1/2" Styrofoam to an oversized piece of plywood (maybe as thin as 1/4" would work). Glue on edge boards (1x2's)Glue a smaller piece of plywood to underside so that the lid fits into a plywood box (3/4"?), but top piece of plywood on the lid is supported by the top edges of the box sides. Reinforce corners of box sides with glue-blocks (though they may interfere with "nesting" unless planned for accordingly).

Not sure how to make lid open or pivot--are things called "flipper-door" hinges that may work. Would have to bevel edges of top to allow it to close on hinges without binding. Note also that these could be noisy--may have to carpet or pad the tops and povide non-slip (like foam weather stripping) on bottom edges of box sides (no bottom).

If you insist on collapsible, make the box sides hinged so the box they form can be sqeezed at opposite corners to "rack" the box flat. I've seen step-stool seat things out of plastic that do that.

on a waterbed box, they have a cross brace that slips apart. maybe that would work to support the dance. make each box a little smaller to slip inside each other

could use a bit more detail on this. Never had an encounter with a water bed.Thinking something with piano hinges??? Or dovetail dadoes that slides together?Marine Engineerfair winds and following seas

Those spring loaded casters would work if one STEPS on the box.But I would be concerned, at least without some experiment, where you might jump on the box with a horizontal movement as well as vertical. They might move sideways before they get enough weight to lock in place.Lot of questions about why the casters (how often are them moved), how compact that they need to be. And how often are they disasembled and stored?One thought is to use aluminum angle "iron" and use quick fasters.http://www.southco.com/landingpages/dzus/That is a start, but look at some of their other product lines.Some of the compression latches could be used to hold parts to gether or box to box if that was needed.Another option would be to use the angle iron and rivnuts. Then ordinary flat head screws through the sides and top..

.

A-holes. Hey every group has to have one. And I have been elected to be the one. I should make that my tagline.

Bill

View Image

How about these corner fastners. They are used alot in ready to assemble desks.

1/4 turn and they come apart.

Or how about bed rail hooks. It might take an extra cleats on the inside of the plywood box. But it would be able to quickly knock down.

View Image

View Image

Rich

I would be concerned with the cam locks with those kind of forces.That is why I sugested mechanical metal fasteners.But the bed rail might be part of a solution. But would need something elese to lock it into place so that the thing will not fall apart if someone kicks the box..

.

A-holes. Hey every group has to have one. And I have been elected to be the one. I should make that my tagline.

Try Simon Lou arts They are a fine arts supply company.

I worked in the industry for a few years and found that

there are strange expectations in the art world.

The construction of the boxes isn't hard, but pleasing

the dancers, artist etc. can be a nightmare.

I couldn't find a Web page for them but they are the biggest

stretcher/panel maker in NYC so it won't be to hard.

PS

Not sure of the spelling for Lou (He's Chinese).

http://www.simonliuinc.com/

That's the one.

My take is that they'll never stand up to dancing on them without the sixth side. Too much torsion on the box when a dancer jumps on/off. The casters are impractical too -- will send the boxes scooting off unpredictably.

Best bet would be a frame of welded square steel tubing, but even that might violate the "no wood" edict.

Of course the best way to make KD boxes is with KD hardware, but none is designed to stand up to the stresses implied.

Another thought-

18x20 that's not very stable if the dancer's get going.

With a dancers weight and accelleration forces at work I don't think casters are a good idea, as others have said.

Reguardless of the hinges or connectors, the top should rest on the sides to take pressure off of the hinges.

You could make them three sided, with a stretcher in the middle sliding in a sliding dovetail piece that is screwed to the legs. The sliders will have to be made of hardwood, cause even BB won't hold up to many breakdowns.

As was said before, the sides could be attached with piano hinges to fold inward, with one sticking up more than the other.

Band any edges with hardwood and round'em off so splinties don't become a problem.

built the boxes yesterday. The box will be part of the dancer as if he were wearing roller blades, so the casters were essential.

We built the boxes out of 1/2 plywood, using door hinges (pull the pin and the break down) glued and screwed. The tops were 3/4, rabbeted to sit inside the box. They seemed pretty sturdy. I dadoed for the bottom of the box, which is floating, rounded off all exposed edges, made handholes. My buddy is pretty happy with them. They go to their first rehearsal tomorrow.

Here's some pics.

Marine Engineer