I’d like to revisit an upcoming project … installing 500 sf of wood floor over a concrete slab. In this case I have the luxury of no height restriuctions … in fact that is part of the project. It’s an enclosed porch that is about 5 inches dropped from the house floor, and they want it flush.

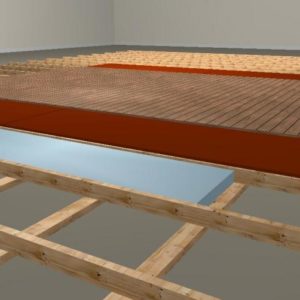

The question at hand is how to fasten the floor joists to the slab. Attached is an idea. Start with 2×4’s laid flat, with a bead of PL, and Ramset every 36″ to the slab. Then 2×4’s standing up at right angles, toe nailed to the runners. These 2×4’s would be tapered as needed to make the final floor flat and level. Rigid foem between the joists. 3/4″ cdx ply glued and screwed to the joists. A layer of 15# felt over the ply. Wood flooring nailed to the ply.

My only concern is the 2×4 joists spanning 24 inches. Is that too much? Actually the span will be about 21 inches.

All I know, I learned from Luka.

Replies

have you considered running the 'standing up' 2X4 the same direction and right on top of the sleepers?

I have the impression that 2X4's at right angles would not be a problem, but no tables/engineering to back it up...

I'm not an expert ;>)

Yes I did consider running the sleepers and the joists in the same direction. But if I need to taper the joists or alter their height to make the floor flat & level, then I would probably have to taper the entire length.

If I install the sleepers, then snap chalk lines at 90 degrees, I can check the elevations only at the intersections, and make adjustments to the joists where they bear on the sleepers.

All I know, I learned from Luka.

Here's a quick method to check floor joist spans.

Take the span in feet and divide by 2. (span = 2 feet, 2/2 = 1)

Then add 2. (1 + 2 = 3) So a 2 x 3 will span 2 feet.

Here's another example. Say you want floor joists to span 12 feet.

Take the span in feet and divide by 2. (span = 12 feet, 12/2 = 6)

Then add 2. (6+2) = 8. So a 2 x 8 will span 12 feet.

Check this against your building codes for F7 oregon - its pretty close.

Another consideration is whether this floor is exposed to rain.

This can cause a number of problems:

1) Water can get through your floor and pond against the battens creating a damp environment perfect for wood rot. (Remember your battens are running across the concrete's fall).

2) Swelling and cupping of your floor boards is likely.

3) A damp environment away from sunlight that can't be easily inspected is perfect for termites.

4) Without a step of at least 2" water can easily flow inside

Check the flooring manufacturer's warranty, some require that the joists be no more than 16" o.c.

The awful thing is that beauty is mysterious as well as terrible. God and the devil are fighting there, and the battlefield is the heart of man.

- Fyodor Dostoyevski

Why do you feel that you need to attach it?

Ever heard of gravity?

Furring strip + 2X4 + 3/4" plywood = 5".

Support it where joist meets rim, and you don't even need hangers.

Our quarrel with the world is an echo of the endless quarrel within us. - Eric Hoffer

Mike: I think the first layer of 2x4s should be treated wood, if that porch slab is on grade (and with who knows what kind of moisture barrier or wicking layer beneath it, and possibly water draining down onto it).Has there been another discussion of wood on slabs? I'm struggling with how to finish a slab with above-slab radiant heating and wood finish flooring. Please advise if there is such a discussion. Thanks, Jim

Would it not be a good idea to cover the concrete with a least a 6 mil plastic before you lay down any wood ? This would be a vapour barrier preventing moisture rising into the wood components.

If you could live with 2x6's, I would install these on 16" centres with blocking where the 3/4 ply would meet, insulate with 6" Roxul and install another 6mil sheeting over the insulation. The joists would be fastened at the house edge and the outside porch edge. If the 5 " is at the house edge and the concrete slopes to the porch outside edge ( gets deeper) you could lay one joist in, mark and set the slope and cut all the joists prior to installation.

An alternative thought.

You could use Trex if you're really concerned. It might be the best use of the stuff -- as plates on concrete slabs. But treated 2X should be fine. Don't double up on your vapor barriers or your structure will be doomed to certain failure. How will the moisture escape between the two vapor barriers? It can't.

Billy

Edited 12/14/2004 7:30 am ET by Billy

I see where your coming from about the double sheeting.

However, my concern is the movement of moisture from the warmed floor side of the room as well as the prevention of the moisture from the concrete side...much like you would have with a dirt floor situation in an unheated crawl space.

Both moisture situations could cause you trouble. If the concrete is bare the moisture would certainly move up hitting the underside of the wood and possibly frosting up if there is no heat below the floor which I am assuming there isn't.

The top side sheeting prevents the moisture from passing into the floor.... typical inside vapour barrier.

To ensure any moisture that may occur between the sheeting on the concrete and the bottom of the wood floor is removed and not trapped would be by venting the space.

Comments and correction welcomed.

Murr

The existing concrete floor has a stamped pattern, and it has been painted. That makes for an effective vapor bariier, right?

I'm sorry ... I thought you wanted it done right.EM>

Paint on any surface is not typically considered a vapour barrier.

Moisture behind or under any painted surface has the ability of causing the paint to eventually peel. It may not happen for several years or it could happen immediately.....depending on the conditions.

For long term you would not want to depend on this layer of paint as a permanent vapour barrier.

I like the idea of using Trex sleepers.

I would be hesitant to cut all the joists to the same size, without first checking all the locations ... that's a lot of work. By placing the joists at 90* to the sleepers, all I need to adjust is small contact areas.

As to the 2x4 or 2x6 question ... it's a long story, one that I would get admonished for. Ok, you asked, here's the condensed version. I am going out of state to help a relative do some remodeling on his house. If that wasn't bad enough, he's a doctor ... two strikes. Anyway, I am trying to make plans based on his verbal descriptions of the house ... "yeah, it's about a 5 inch drop" ... when I'm not even sure he can read a tape. So, a lot of my questions and plans are very fluid, pending the site visit.

All I know, I learned from Luka.

I'd be inclined to run 15# under the flat 2x4, and just ramset it. The paper will keep the 2x from direct contact with the concrete, and ought to mitigate any noise from structural working. Finding rolls of the precut for window flashing would be just the ticket, I'm thinking.

Now, whether you need to isolate the finished flooring, too . . . That's a "probably," and to match the way the insulation is going in.

Harder part will likely be when the concrete floor is sloped, and the wrong way (you already said this was a double-bad deal anyway, right? <G>) Can be a real pain cutting those "weep holes" in all the sleepers (especially when they all shot down with not one problem, not one over or under cut, not one misalignment . . . )