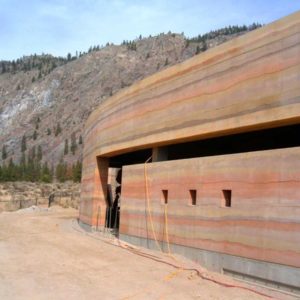

Here are some shots of a project I’ve been working on the past month. It is going to be an interpretive centre owned by the Osoyoos Indian Band in Osoyoos, BC. The site is on one of the few remaining pieces of desert environment in Canada. The Sonoran desert peters out in the Okanagan valley just inside the Canadian border, and the band has preserved a significant chunk of it. They have had a temporary visitor centre on site for 3 years and now the permanent structure is being built. This is an enterprising group; close by they have a vineyard and winery, an 18-hole golf course, a townhouse development and a 60-unit hotel just being started. Some of the band members we have working on site have had continuous construction work there for more than five years.

The most obvious feature of the interpretive centre is a rammed earth wall. It is formed in a similar manner to a concrete wall, then sieved clean soil mixed with colouring and cement is poured in and then compacted by jackhammer with a special ‘foot’ on the bit. Different layers are added to give the banded colour effect you can see in the photos. The wall is 18″ thick and 17′ high. The back wall is a concrete retaining wall as the building is cut into a fairly steep hillside – the idea being that it will blend into the desert surroundings. Roof is suspended concrete slab that gets a rubber membrane then 2 ft of soil and landscaped with sagebrush and other desert vegetation.

Architectural details are stark but tricky. All concrete corners are 90 degree, no chamfer allowed, so every joint in the form is siliconed to prevent bleed through. There will be no baseboards in the finished building, just a small concrete reveal tapering from 1/2″ wide back to 1/4″. These all had to be cast into the walls at exact height as the floor slab is not placed yet. Lots of odd angles, non-parallel walls, curved walls, a real layout delight. Plus all in metric because there is some federal funding.

I’ve included a shot of some stairs I formed last week. No nail hole permitted in the walls or floor slab, so all risers are held in place by feather wedges. The inverted stringers are braced back against a wall. Just to make it fun, the wall between the two stairs is not parallel to the walls on either side, so the stairs on the right get wider as you go up, and vice versa. I made sure to put a deep saw kerf in the back of the riser forms on the left stairs so they can be broken out easily, as they will be firmly wedged in by the concrete pressure.

Replies

Cool!

The color on that wall is beautiful. Doubt you could paint it and get results that good.

Doug

Wow- that's spectacular! Amazing what you can do with damp dirt and cement!

Yes it's impressive but so was the cost. It was done by subcontractor for $350,000 CDN. Enough R value in the wall that no other insulation is needed so it is exposed inside and out. Lignum est bonum.

So I guess when someone tells you to "ram it", you don't take it personal ???

Hardware: the parts of a computer that can be kicked. [Jeff Pesis]

Wow

I just set "front wall.jpg" as my wallpaper !

Do you have a shot of that straight on from the front ?

Man this does give me ideas...

Thank you for the great thread. More pics please...

I don't think I could get a full-width frontal shot with my simple camera because the ground falls away fairly steeply. Here are some other shots, one shows the wall straight on in sunshine but from the inside.

Interestingly they had some samples tested that indicate hardness comparable to 15 MPa concrete. I don't know the conversion rate to psi but we use 30 MPa for sidewalks and slabs, so this stuff is fairly hard, similar to weak concrete.

The first 'sample' wall they did was for a sign at the entry to the site, about 6' long by 4' high. The architect didn't like it because it came out looking too smooth and manufactured. The solution was to slightly relax the clamps holding the forms together at the end of the day after each session. The following day the clamps were tightened up again and more soil poured in and rammed. The result was that each successive layer was slightly proud of the one below, giving a similar look to the cold joints sometimes seen in older concrete buildings. Should look really striking when lit. Outside there are recessed lights set into the walks.Lignum est bonum.

Reminds me of those jars of sand we had when I was a kid. Different colors of sand layered in a clear glass jar.

jt8

"Real difficulties can be overcome; it is only the imaginary ones that are unconquerable. " --Theodore N. Vail

Thank you Sly.Did they add coloring to the dirt concrete mixture, or is that just the way it turned out naturally ?

But it's amazing how we've reached the point where we will go to war over anything that bothers us. I think we all have the right to walk away from things that bother us. If it happens in our homes, then we have the right to send the offending person away. Anywhere else, we take a walk. But when did it become okay to think that we have the right to fight with people who annoy us? And when did a little consideration of others become so unfashionable that we can't do it? A little bit of cooperation and consideration would make all of this a whole lot easier. Rules at the job are always appropriate. But we have become so used to imposing rules on how others chose to live their lives that we are ready to beat them for failing to adhere to them. -SHG

Most of the colours are artificial. The soil came from right on site. It is a very fine glacial silt with a small clay component.

Despite the cost savings of not having to buy and truck in concrete, this is a very expensive method. The forms have to be extremely sturdy, even though there is never full liquid pressure. But so striking visually.Lignum est bonum.

Real pretty stuff, even if it is expensive.

I noticed some areas where the walls continued up over openings below. What did they use for support ? Standard lintels?

Don K.

The openings are supported by a combination of formwork (heavily braced door and window bucks), steel reinforcing, and the structural concrete in the rest of the building. It's hard to see but there is a concrete column just inside the wall about halfway along the length of the window opening. The suspended roof slab is keyed into the wall, and there are continuous rebar dowels tying them together as well.

As a side note, the HVAC is complex too. There are radiant tubes in both floor and roof slabs, plus some buried ductwork that runs through the subgrade and comes up in partition walls. The few suspended runs of duct are all concealed by T bar in the service areas of the building; the most part there is an unimpeded view of the roof slab.Lignum est bonum.