Recommendations on concrete flooring in elevated bathroom…..

Howdy folks,

So I have been renovating my house, slowly, room by room. The master bedroom is done, and the master bath has been gutted for a few months now. I am finally able to start approaching this project and I need some recommendations!

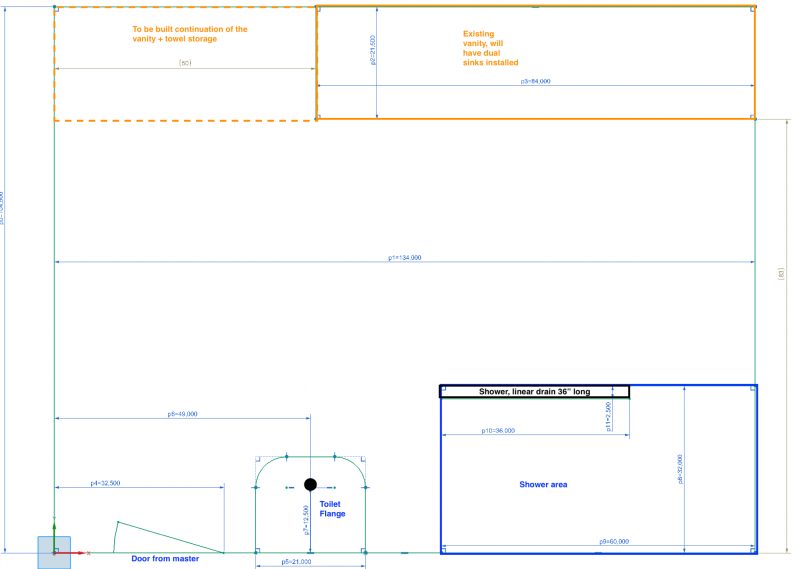

Here is the layout of the bathroom:

My master suite is elevated. The rest of the house is on a slab (not that that is relevant…).

The master bathroom is sitting on 1″ plywood with this crawl space below it:

I want to have a concrete floor in my bathroom that goes wall to wall including the curbless shower. I assume i am going to have to paint water proofing undercoating to all the wood and up the walls some what. If you all have recommendation for painting underlayment let me know.

The issue is this: From my master bedroom to the bathroom, i only have as thick as the engineered hardwood to fill with concrete otherwise there will be a discontinuity over the bathroom/bedroom threshold. Hard to explain, easier to show:

I don’t know why everything is coming in upside down but whatever. On the left, the unfinished floor is the bathroom. On the right is the glued down engineered hardwood flooring in the master bedroom. If possible, i’d like not to have a threshold discontinuity between the concrete and the hardwood. I’d like not to even have to put a threshold piece of molding over the transition, and just have a nice clean line. I know i will have to water proof that edge of the flooring.

Okay, so i want to have my concrete floor about 1/2″ thick, to bring it up to the level of the bedroom hardwood. I’ll want it to slope, if anything, away from the bedroom so any flooding won’t be inclined to go into the bedroom and ruin the wood flooring. Then for the shower it needs to slope of 1/2″ per foot (so i hear?). Clearly that slope isn’t going to work for my shower with this concrete depth….

I’d like some recommendations from you all on:

1. Ideas how to deal with this this concrete layer to prevent cracking of the floor. I anticipate some cracks will happen, i’m okay with that and have a cool idea to fill them. But i’d like to minimize if possible.

2. Ideas on how to deal with the shower pan.

3. What concrete mix i should use for the floor/shower. Should i use remesh in it?

4. What waterproofing under layer paint i should use.

I already purchased the Schluter Systems Kerdi 54-sq ft Orange Plastic Waterproofing Tile Membrane. I might just end up using it on the shower walls and useing a paint on solution for the floor? unless you all recommend otherwise.

Thanks so much folks!

-Ben

Replies

If I understand you correctly, there's little more than a 5/8" (thickness of engineered flooring) difference in height between the bedroom floor and the subfloor in the bathroom. Pouring concrete over such a smallow area is not recommended. Typically, you lay 1/2" tile backer (such as Durock) and follow that with 1/4" thick tile, for a total rise of 3/4". You could buy a pre-formed "styrofoam" shower pan (properly sloped) to serve as base for your tile work. Over this you lay the Schluter mat. Then you tile. The foam base will be at least 2" thick. This means that the shower floor will be above the rest of the bathroom floor. You could form your own shower pan. The point I am making is that, no matter how you form your shower pan, it will lie above the plane of the bathroom floor.

Likewise, the (assumed) 5/8" difference in elevation between the bedroom and bathroom, is not enough to accommodate a tiled floor. Tile needs a mininimum 1" of solid subfloor over which you lay tile backer. Tile back ususally does not count towards floor stiffness and minimum thickness.

It seems to me that you will need a transition molding between the bedroom and bath room floors.

"Concrete" is not typically used for a bathroom floor that is less than 3.5" thick There are weight issues as well.

Do water proof the subfloor in the shower. Install the shower base material. Then comes the shower mat. Be careful, Kerdi Schluter products require NON-modified mortar. Water proof paint the walls if you want, and then coer them with a KS wall membrane material.The idea is to create a water-tight, layered shower enclosure .

You can buy kits consisiting of a shower pan, with stone-like surrounds on three or 4 sides. Expect to pay around $2,000 for a 5" long by 36" deep kit (see Swanstone et al).

The questions you are asking lead me to believe that you are a DIYer with limited tiling experience. Be carefull...because you will never know about a leak until the damage is done. This sort of project is best left in the hands of a seasoned pro. Photo 1 shows the shower floor at 3.5" below the bathroom floor. You see the isolation membrane laid into a bed or mortar. Photo 2 shows how the shower bed is formed with stiff "mortar" along the edges to act as guide. The last photo shows the shower pan, sloped 1/8" per foot of run. The drain is embedded in the formed floor.

What is the spacing between floor joists? It looks like you need more support. Tile is unforgiving and will crack if there is any flex in your subfloor.

Thanks for responding. This was my concern too. The bathroom used to have concrete baker board with tile on it. The concrete backer obviously stiffened the floor significantly. The joists are 48" on center. I was thinking about maybe cross bracing between the joists with 2x6's or similar between the existing joists to help support the 1" plywood floor. Do you think it's necessisary? It'll be quite a PITA to get them in there but if needed...

B

"concrete" board does not increase the stiffening of a floor system.

What the tile shop had me do about 30 years ago is staple (with fence staples) a piece of "expanded metal" to the floor, then skim with conventional thinset. Added up to about a half inch, made the floor stiffer. That bathroom has been fine since. This was over 2x6 joists on what looks like 12 inch centers.

The lath acts as an antifractur membrane. You can do the same thing using schluter products or thinsetting cement board to the floor. all of them work but they dont add much in the way of stiffness. If the joists are spaced so far apart the plywood will bounce and crack the tile. This floor needs a lot more support added.

I'm not sure what the terminology is, but this expanded metal was much more robust than normal metal lath. It's been a long time, but I'm guessing it was about 10 gauge. Most lath I find on the web doesn't state a gauge, but the one I do find says 16. As formed the stuff created the full 1/2" thickness, with the thinset just filling in the gaps.