Retaining wall made like marine bulkhead

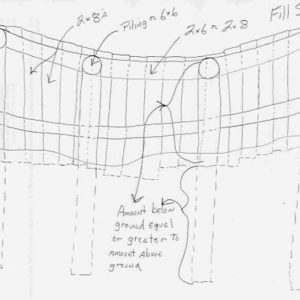

I’m thinking of building a retaining wall the way marine bulkheads are built. Deeply set vertical posts about 5′ apart, 2 x 10 horizontal stringers behind the posts on the fill side, then 2 x 8 vertical strakes behind the stringers driven partially into the ground, then cut even at the top. I’m interested in doing it this way because the grade varies greatly and will be difficult to level. The highest point of the wall will be about 4 feet high. Does anyone think this will work?

Replies

Assuming you like the look...it should work ok, but I think you might have a problem with the 2x rails being a little weak.

Do it right, or do it twice.

It will work for as long as the posts or pilings last, If it is going to be as curved .as your drawing implies, you can use doubled up 1 bys instead of 2 bys.

SamT

we usually construct retaining walls with horizontal 6x6's, if the grade changes you can stair step the horizontal mambers. A curve can be achieved building the wall segmented.

Either way your going to need "deadmen" every so often to hold it.

Depends on how you plan on installing the 6x6's or piles. If you auger holes for them and then drop 'em in and backfill the holes, I'd say they'll move over time. If you drive them with a pile rig, it should work fine, but your looking at $5-10k just to get the rig to show up. Maybe pouring concrete around them like fence posts would work, but I'd set them twice as deep as the wall is tall just to be safe.

Bob

I've been paying attention to a retaining wall along a road on Monterey, California.

It consists of a series of I-beams as posts and the profile of the beams serve as slots for what appears to be approx. 8x8 wooden posts, presumably pressure treated.

The wall height is approx. 10' tall and holds back quite a bit of earth from sliding down onto the road.

The span between the i-beams escapes me, but I'm guessing around 8-10'.

Noticed it back in 1999 and recently got a chance to take another look - no signs of deterioration.

I have no idea how deep the i-beams are buried.

Cal-Trans used that method for temp. retaining walls while digging the underpasses for the bridges being built in Santa Barbara CA. The Pile Drivers would come out and sink the I beams about 15-20 feet into the ground, then crane would set the 8xs in place.

Jen

This is sorta Deja Vu....maybe we had this discussion before.

Anyhoo....the method seems very effective and durable for a temporary wall, especially for a residential application.

The look is actually very pleasing for what it is because of the exposed wall is a continuous flat surface.

However, I'm not sure about having to pile drive the beams 15-20' into the ground. That could be very expensive for a backyard project.

I am impressed with how well the wall has held up and the amount of earth (a very tall hill) that it is holding back.

And it seems to be a very fast way to erect a retaining wall.

6 x 6s with tie-back deadmen like Panama mentioned eliminate the need for piles.

Excellence is its own reward!

re -

6 x 6s with tie-back deadmen like Panama mentioned eliminate the need for piles.Excellence is its own reward!

-----

Yes, deadmen would lessen the need for deep pile driving.

However, I would be interested in using I -beams as slotted vertical members that can accomodate the 6x6 or 8x8.

The idea of using the 'screws' sounds promising and I see those used quite a bit these days for large retaining wall projects (for highway construction) in our area and have noticed them on residences, some for stopping leaning retaining walls.

so...I-beams, PT posts, and the 'screws'.

Maybe a bit more expensive in material but more simple to execute then other forms of walls ?

Just don't call them I beams. If they've been driven into the ground, chances are they are real piles, H section.

Just don't call them I beams. If they've been driven into the ground, chances are they are real piles, H section.

------

Yes, H section it is.

I'm not fully up on all the jargons, obviously.

Thanks for pointing that out.

Oh, I was just trying to be anal; it's Monday, after all.

anal-retentive (n): a person who worries about whether or not a hyphen is used when spelling "anal-retentive".

Anyhoo......when I need a steel beam for the purpose under discussion, there is such thing as an "H section" that can be asked for by that name in several standard size/profiles ?

Yes, indeed, they are called "Steel H Piles".

PS - I love your name. Don't we all......

re - Yes, indeed, they are called "Steel H Piles".

PS - I love your name. Don't we all......

----

Thanks for the proper name.

It will help when I have to sound like I know what I'm asking for.

As for my name, I needed something that reflects my status here as an amature layman.

I'm not in the trade as most folks are here and not in any position to speak authoratively on any subject.

Been a long-time subscriber to the magazine, though.

Well, I picked TenPenny because to most folks here, it probably conjures up images of nails, but to those of us from the homeland, it's an ALE!

Ten-pence?

Who ever invented work didn't know how to fish....

Although I'm more partial to stouts, I think I've seen that Ten Penny label before !!

Yes, indeed, they are called "Steel H Piles".

I thought that's what I been sitting on the last few years.

Samt

If we really want to get technical, even most of the horizontal members people refer to as "I beams" aren't true "I beams"- they're wideflange beams, as referenced by the "W" in the size callouts. Most mills have stopped rolling the "S" shapes which were the "I beams" of yesteryear, and I haven't seen one spec'd on a drawing in years. Probably just another example of facial tissue being called "Kleenex" because the brand name's permeated the market.

Bob

IMHO,

I honestly don't feel the 2x horizontal stringers are stout enough. In essence, the stringers are holding nearly all the weight (force) pushing against the retaining wall.

I used to be involved with the temporary "shoring" of excavation holes during pipeline repairs and such. We used 4X6 s as horizontal stringers and then nailed vertical 2X12s behind these. Based on past practice with this method of shoring, I think you should use at least a 4X4 for your planned retaining wall stringers. Also, adding a middle stringer would greatly increase your retaining wall's strength against the "push" factor.

Based on the mentioned steel piling method, the I beams are the posts, and the 8x8s ( railroad ties are also used) act as the retaining wall. There are no stringers in this method, because the 8X8s are laid horizontally in between the I beam slots.....so if an 8X8 is the "norm" ( which it is) in this type of system for holding back the earth, perhaps you should re-think your original planned stringer thickness/strength capabilities?

One more question....why not construct or rent some forms and pour a concrete retaining wall? Is your wall just way too long or what? You could probably build just a single wall form that would give you a wall thickness of 6 or 8 inches, and this should hold up just fine, so long as you plan for some weep holes in your wall.

LOL nomatter what type of wall you plan to build.

I myself am preparing to build a concrete retaining wall at my own residence. Although my wall will only be 3 feet high at it's highest point. Wall length will be approx. 30 feet.

Davo

Davo,

A concrete wall would be my first choice, but the grade varies so much over its 60' curved length, that digging for a footing would be a real bear. Access is limited and the site is steep, so any digging would need to be done by hand. Oh yeah, it's sandy soil also.

moduler concrete blocks?bobl Volo Non Voleo

The missing part from your drawing is the tie back cable. I have examined a few bulkhead walls being built at the coast and every vertical has a galvanized eye bolt thru it near the top attached to a piece of 1/2" steel cable which is then fastened to something behind the wall below grade. I don't know what they were attached to but I suspect it was a 6x6 block. The cable was run back in a trench that was already backfilled. That way you can crank down on the eye bolt to tension the wall. Also they used a 4x6 laid the flat way to support the vertical pieces

When I used to build retaining walls from 6x6's laid flat I would sandwich a 2' long piece of 6x6 between two 8' long deadmen going back into the slope and ussually step the wall back 3/4" at each timber. The largest one I ever built was 14' high and 300' long and has an apartment complex swimming pool behind it. This was 15 years ago, and I still ride thru the complex occasionally to check on it. So far so good!

I also built one wall, only about 3 to 4' high against a slope where we couldn't trench for deadmen. We used mobile home anchors into the existing slope. I rented a machine from the mobile home supply house which screwed the anchors into the earth. I used metal straps to attach the wall to the anchors.

I had a wall built about 8 yrs ago, total about 250' X 5' high. We used railroad ties with deadman anchored by helix utility poles anchors screwed into the earth with a Bobcat with a posthole drill. The helix anchors then had a eyebolt attached and bolted through the face of the verticals. It was fairly simple and used easily obtainable material and equipment. No problems or failures have been observed yet.

Bob