I am trying to build a 48’x40′ pole barn. I will be using 6×6 poles on 8ft centers with 2×6 framing in between, with 1/2” osb on the outside. My plan was to nail and glue 2×12’s with 1/2” ply wood in the middle to make a 48ft ridge board “this will be supported by 4×4’s and 2×6’s”. I was planning on using 24ft 2×10 as my rafters on 2 ft centers. “6/12 Pitch”. my question is. Is this possible lol. I only have a $20,000 budget. Thanks for any input

Discussion Forum

Discussion Forum

Up Next

Video Shorts

Featured Story

Join some of the most experienced and recognized building professionals for two days of presentations, panel discussions, networking, and more.

Featured Video

SawStop's Portable Tablesaw is Bigger and Better Than BeforeHighlights

"I have learned so much thanks to the searchable articles on the FHB website. I can confidently say that I expect to be a life-long subscriber." - M.K.

Fine Homebuilding Magazine

- Home Group

- Antique Trader

- Arts & Crafts Homes

- Bank Note Reporter

- Cabin Life

- Cuisine at Home

- Fine Gardening

- Fine Woodworking

- Green Building Advisor

- Garden Gate

- Horticulture

- Keep Craft Alive

- Log Home Living

- Military Trader/Vehicles

- Numismatic News

- Numismaster

- Old Cars Weekly

- Old House Journal

- Period Homes

- Popular Woodworking

- Script

- ShopNotes

- Sports Collectors Digest

- Threads

- Timber Home Living

- Traditional Building

- Woodsmith

- World Coin News

- Writer's Digest

Replies

A ridge BOARD can almost be made out of cardboard -- it serves no real structural purpose but simply facilitates the joining and spacing of the rafter ends. A ridge BEAM is an entirely different beast, and must be carefully specified.

Generally speaking, you can use a ridge board if you have some sort of reasonable rafter ties (ceiling joists being the usual). Lacking rafter ties (and your drawing shows none), you need a beam.

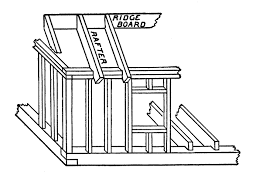

Ridge Board

First the drawing is just to show what i was talking about "not mine". my real issue is if 2x10s on 24in centers will be strong enough to have a total span of 40 ft . i will be using plenty of ties.

Hi Pierce, If this is a ridge board then the rafters don't impart any load on it. So your question about 2x10s being strong enough for the span is inconsequential. I assume you are wondering if you can join peices to make a singular ridge to be put in place on posts before the rafters. If this is your question, then there are many ways to splice multiple boards together to make one ridge. Easiest would be glue and screw 2 layers of 1x12 pine with the joints staggered. Hope that is helpful. Also remember if this is a ridge board not a ridge beam, you need rafter ties to keep your walls from being thrust outward.

Hi Pierce, If this is a

Sorry. Double post.

i will be using plenty of ties.

I'm not sure you know what we mean by "rafter ties". If you use a ridge board then each pair of rafters must have a joist running between the two far ends (to make a rigid triangle), or, at the very least, some sort of "tie" that is somewhere below the point a third of the way up each rafter.

We're not talking simply having the rafters "tied" to the wall plate, but rather opposing rafters tied to each other so they won't spread apart.

Ridge Board

First the drawing is just to show what i was talking about "not mine". my real issue is if 2x10s on 24in centers will be strong enough to have a total span of 40 ft . i will be using plenty of ties.

If it is the 2x10 with 20 ft rafter span you are concerned with, the simple answer is no.

Online span calculator here: http://www.awc.org/codes-standards/calculators-software/spancalc

I think you should be looking at trusses.

is this something you are getting designed by someone qualified? or did you just buy a design online? what you are proposing for a ridge board is something you can do but there is no real reason to. With a ridge board you can set the ridge in sections (manageable ones) but you can use this kind of ridge without adressing the issues Dan mentioned and a slew of others.

I couldn't upload a photo so im making a new post. Thanks

Photo

From the original poster:

I couldn't upload a photo so im making a new post. this is what im going for 48'x40' pole barn with 6x6 poles on 8 ft centers and 2x6 framing in between. I want to use 2x12 with 1/2'' ply wood in the middle. rigde board with 2x10 rafters. thanks for any input

You have access to 24 ft 2x10s?

I couldn't upload a photo so im making a new post. Thanks

I couldn't upload a photo so im making a new post. Thanks

keep dreaming

Forget about your span issues. At $10/per sq ft, you have a structural issue with your budget.

do-able for a pole barn with dirt floor, IF OP is in a no-permit-needed-area.

My last build for a shop (heated with walls and foundation) was $1800 for permits for 780 sq ft

($2.30 sq ft for nothing, basically a tax)

Using garage sale finds, surplus lumber, etc. built it for about $12 sq ft, and not junk.

Have built 'pole barn' type structure 20 ft by 30 ft with surplus ;materials for under 50 CENTS per sq ft.! Mpst of that cost nails and power and fuels.

PS: thank you for not suggesting he hire an engineer <G>

new material, no engineer copout answer... brace yourselves!

Unbending and straightening old nails is not too bad, it is the laying them in a line correctly and collating with hot glue gun that gets tedious <G>

Once you get your budget expectations in line, you might want to cosider using engineered lumber (i.e. TJI's or WI's) for the rafters and LVL's for your ridge beam. If you have a good material supplier, you might be able to take care of the professional engineering as part of your order. If this project is permitted, chances are you'd be limited to prescriptive code without engineering support. In that case I imagine you can look up span tables just as easily as any other bozo on this forum.

If you need cost effective nails to stay within budget, you might be able to get a deal on re-collated salvaged nails from junkhound. Keep in mind that it largley depends on whether he is using a (yard sale) protractor to guage them correctly for your particular nail gun.

As you've drawn it...

As you've drawn it, you would need a "ridge beam" not a "ridge board". Because you have no resistance to the walls spreading apart at the top when the roof is loaded, a beam is required to keep the roof from sagging (and falling in) - at 48', it would be a good sized glue lam - it will be supporting half of the entire roof load.

If you had "rafter ties" or "ceiling joists", they could provide the support needed to prevent this lateral thrust. An example of a rafter tie would be a horizontal 2x6 bolted to each side of opposing 2x10 rafters about halfway down the rafter on each side. An example of a ceiling joist would be a 2x10 set on the plates on each side of the span and nailed into the plates and the ends of the rafters (won't work in your case because of the 40' length) - this would be similar to the bottom chord on a truss. In these solutions, the member running down the middle of the span would be a "ridge board" and performs as a bearing and nailing surface for opposing rafters and a way to set them in place during construction. The problem you're going to have is the sag your homemade member will have over 48' and how to keep it from buckling sideways while putting it in place.

Another way to resist this lateral thrust would be additional roof structures on each side of the main building...your later cross section sketch seems to indicate this might be the case. This - as with all of the solutions - requires professional engineering.

The struggles you are up against is why almost every structure like this is now constructed of engineered prefabbed trusses...they're lighter, stronger and cheaper - and would be my recommendation.

Good luck...

Agree with trusses. Quick, easy, cheap.

KK

How are span and load limits calculated for a doubled or tripled TJI with filler and backer blocks used as a ridge beam (or header) as attachment point for the new rafters for a shed-roof addition?

I live in Seattle and want to do a 23' wide shed-roof addition to my 1.5 story cape-cod in residential Ballard. ForteWEB was only offering LSL/LVL/PSl/Glulam and lumber options. Craning in a heavy beam is not feasible due to a spread of adjacent high-voltage transmission lines, so I'll need to piece something together with TJIs or lumber.