Howdy,

I’m working on building a playhouse for my kids. This is my first bigger construction project I’ve undertaken and have been spending quite some time laying the project out in Sketchup and perusing the forums for tips. I’ve come to a point where I need some advice (probably won’t the last time along this journey.) I’m loosely working off of Ron Hazelton’s “How to Build a Playhouse for Children” as I like the design. Problem is, there are no written plans to be found… anywhere. Enter Sketchup and Matt Jackson’s fantastic video tutorials.

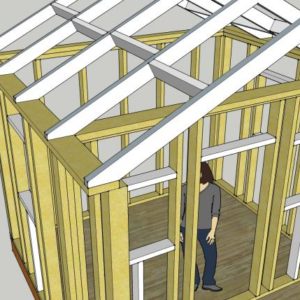

After building the playhouse digitally and being able to visualize it up close, I’ve grown concerned with the roof structure and how it sits on the top plate of the walls. As you can see from the picture, the top plates are 2×4’s with 2×6 double top plates on the side walls to provide a ~2″ overhang. The rafters are not providing an overhang and as such do not have a birdsmouth (that is, the rafters sit directly on the top plates.) So my question is… is this dangerous? Will the forces on the roof cause the 2×6 to separate from the 2×4 or could some other craziness occur because of this less than standard rafter/wall joint (or… is this a common construction method)?

Secondly, I live in Vermont. We get snow. Lots of it some years. I am planning on a 5:12 or 6:12 roof (leaning toward 6:12). Is this adequate? I didn’t want to get too crazy with the pitch as the playhouse is in an area of the yard where a tall roof may not fit aesthetically.

Oh, and this is my post to Fine Homebuilding… What a wealth of info housed here!

Thanks in advance for your thoughts.

Vtterp

P.S. I should mention that I omitted a 4×4 beam in the sketch which will span between the two front porch posts.

Replies

This is a pretty small scale structure, but you may want to consider how you're gonna resolve horizontal thrust of the roof loads (particularly LL of snow). Your drawings do not show a bearing ridge beam or rafter collar ties; two common methods of resolving horizontal thrust in framed structures.

BTW, love your use of Sketchup for modeling and studying your project! Great (free) resource.

Gussets

My thought was to use gussets to strengthen up the rafters and omit the ridge beam. [I have them mocked up in another sketch. As I was changing roof pitches I chose not to "rebuild" them over and over. I'm still learing Sketchup so I often take the long route of recreating things.] Do you think this would be sufficient or should I plan on adding the ridge beam in? Seems like the rafters would be easier to construct without a ridge beam as I could build the rafters on the ground and then place them on the walls...

Sketchup is indeed amazing. You can easily visualize all the materials you'll need, sizes, angles etc. So much better than my first chicken scratch drawings on a piece of paper.

Thanks for your insight!

Gussets would be a good idea (essentially rafter ties). You probably only need 1x stock (4 or 6) for this. I would at least place them at your rafter blocking location height if you're not inclined to run them as collar ties (at plate height).

Suggestion: If you pre-fasten all your rafters together with the 2x6 top plate with Simpson L50 (w/#9x1.5" structural screws) on both sides, install 1x gussets as discussed, and install 2x blocking as shown, then you could probably frame the whole roof structure on the ground. The Simpson L50 will give you a bit of moment connection as you move this thing around rather than risk toe nails coming loose because of racking during the lift. The metal tie angles are also a better connection than toe-nails.

Anyhow you probably can lift it rather easily into place on top of your 2x4 wall top plates (maybe get a buddy to help). Then spike (or better yet lag screw) your two plates together. If you feel you can (or want) to lift roof structure up fully sheathed, then you can fasten the plates together from underneath by screwing the two plates together from in between 2x4 stud bays. I would use the 3" long SPAX structural lag screws for tying plates together. Predrill the first plate with 1/4" clearance hole for best connection...and use plenty (at least 2-3 per rafter bay).

Tip: buy a cheap impact driver kit for about $200 (if you don't have one already) to work with on this project. It makes easy work of the type of screw fastners mentioned. Drives 'em like butter.

Cheers!

This is, of course, a playhouse, not a cathedral. While your concerns are conceptually justified, the forces involved are not enormous and even if your construction is less than perfect it's not likely to result in catastrophic failure.

Basically, there is a downward force on the rafters, wanting to force the rafter ends apart. This force is resisted by fastening the rafters to the top plate. Your biggest challenge is probably to achieve a good connection between rafter and plate. A couple of well-placed 16d nails would probably suffice but you may want to use 20d nails or structural screws.

The next challenge is keeping the rafters from forcing the top plates apart. In conventional construction the joists do this, but you don't have conventional joists, just the top plates on the front and back walls. There is certainly sufficient "beef" in those plates to do the job, but you need to take care at the corners to assure that side plates are solidily connected to the front/back plates, so the corners won't pull apart. 16d nails through the overlapped plates should be more than sufficient for this.

In the Hazelton "plan" I was

In the Hazelton "plan" I was slightly surprised to see that all of the walls were simply connected by single 2x4's perpendicular to each other. I guess, though, in retrospect most shed / playhouse walls are constructed like this if there is no interior finishing required. I trust/hope the triple stud corner (or at least a double studded(?)) corner will provide enough surface and meat to secure the walls to each other and thus the top plates in check under load.

Thanks for your thoughts.

Most importantly, the top plates need to be secured to each other. You shouldn't depend on the wall below to hold the corners together.

I'd put in a single ply 2x ridge beam and forget about it. The roof isn't big enough to get excited about.

Yeah, there's something to be said for the ridge beam. It would have to be cantilevered in the front, though, and one would need to install a header above the door to support it.

Ditto..

What boss said about the roof structure. It'd take serious building malfeasance to make it fail from loading.

Now I don't know diddly about what happens in Maine but for most of the country a proper roof overhang is make or break for any structure. And you don't show any to speak of.

Rick Arnold did a wonderful video series on building a shed which he details how to make on-site trusses. Take a look and see if this truss menthod works for you or answered your questions.

https://www.finehomebuilding.com/videos/video.aspx?id=127667&nterms=127604

You don't give any dimensions for this structure but in looking at the rendering it looks to be as small as 6'x8'. If so, this is really tiny for any serious structural concern. I would think the 2x6 top plate would be sufficient to withstand any outward thrust. But if you want to be conservative then use a 2x8. The additional width will give a stronger shadow/overhang and might be more attractive. I wouldn't use any gussets on the rafters especially if the ceiling is open. They'd just clutter up the interior. A ridge beam is simply more lumber that isn't needed. You should also look into the methods of framing that minimize lumber needed. As you've drawn it, the playhouse is way overbuilt. Why do you have blocking in the walls and between rafters?

Sorry for the delay... life's been hectic and the project had to take a back seat for a few days.

Thanks for all the input. Again this is my first "bigger" project of which there is some skin in the game (i.e. the kids will be inside of it) so I wanted to make sure I wasn't erring too far on the side of incorrect practices.

To respond to most of the questions... It is a small playhouse - 8'x8' footprint with a 6'x8' structure (the roof will be 8'x8' and cover the "front porch." I think I've decided on going with the attached plan (no ridge beam, smaller gussets, Simpson strong ties on the rafter to top plate connection and timberlok connectors.) I was trying to recreate a design built by Ron Hazelton which didn't have much overhang on the sides and included rafter blocking. This house has about 1.5" overhang (hard to see in the image), however I have been toying with the idea of just creating common rafters with a larger overhang as I've surveyed playhouses and sheds around my neighborhood. These cuts simply seemed easier.

I am happy to see that the general consensus is that I don't have much to worry about re: loads etc.

Thanks again all!

Remember.....

Come back with a shot of the finished product!

I had a thought or two -

Why bother with a 2x6 2nd top plate? Why not just use a single 2x4 top plate and cut the rafters a little differently?

The way you have it now you have to line up the rafters with the edge of the 2x6. If you just use a 2x4 top plate that's not a concern.

IMHO the angle brakets you have a re a waste of time. If you want to hold the rafters down, consider something like a Simpson H2A:

http://www.strongtie.com/graphics/products/large/181b-2013.gif

It would tie the rafters directly to the studs.

Complete Custom Home Building Process

Hi guys, we are expert for making custom house this is the best home that is best home for all seasons we are provide custom home building services in Texas. Here we will provide step by step spam link removed. we also sell another stink'n spam link removed at affordable price.

Custom Home Building in Georgetown & Custom Home Building In Austin

should have known, being from Texas and all. Down there I'd be horse whipped and run outta town.................maybe tar'd and feather'd.........................whoa, maybe shot on site.

You ain't from Texas.

But I wish you were tarred and feathered.