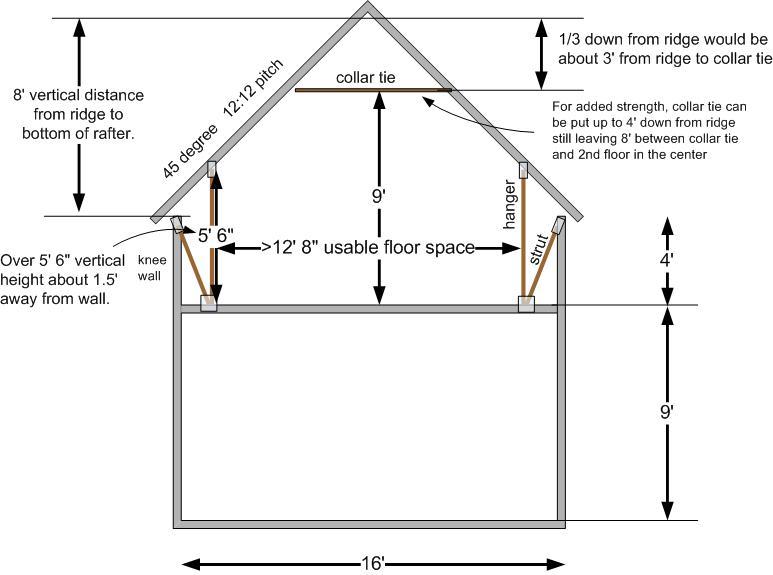

Roof structure design using knee wall, hangers, strut for support

Talking with local builders I’m getting two responses to this design:

1. No problem.

2. Problem.

For the first group I wonder if they have actually calculated load and whatever is required to satisify local building codes.

And for the second group I wonder if they understand how the hanger & strut distribute the load to the floor joists.

I don’t know who to trust. Does anyone have 1st hand experience building as per the drawing below?

What am I missing?

Replies

Well ... That is a type of Truss. BUT.

As to your first question as to whether "they calculated the loads"... Well BINGO!

I will bet everyone here will tell you to see an engineer.

You might also just consider buying trusses and the beatuy here is that the truss company will engineer it for you, in essance, free!

i would bet an engineer will charge you $800. My experience is engineers will charge you $800 to look at a door knob or to desing a shear wall for you or review a beam.... $800. Ok I exagerate, but you will pay.

Go trusses if you can.

Assuming your floor and rafters are sized correctly, and a monkey can find schedules for that, your concern is the wall spread as your collar ties are too high to handle that. Your spans are very doable.

"your concern is the wall spread "

Exactly right. I would think that the hangers and struts would mitigate that. But I'm not that type of engineer.

I'm trying to avoid a 2-story structure because it would be, I think, just too big for its location. It wouldn't look right, I think.

Won't engineered trusses take up too much room and reduce the standing room area? Are there alternatives that allows the kind of head room I'm looking for?

How about this: Barn roof on a knee wall?

How about this:

Can I put a barn roof on a knee wall like this? My goal is to get a large "attic" AKA 2nd floor storage area.

Will an engineered barn roof subject the knee walls to spread?

Not that big of a structure.

Your structure is just not that big and I am pretty sure either design can be build as a truss. I think the first design would work, but I might guess the knee wall might need to be pushed toward teh middle a bit more in order for that diagonal suppor t member to work properly. A truss company would know in minutes if not seconds. The second design might be trick for an ametuer to raise... a floor member as in the first design (assuming floor is part of that truss) would make it easier.

I really think a manufactured truss would make this super easy and not cost you much over stick build materials especially if you end up paying an engineer to engineer the stick built plan.

Yeah, I'm sure you are right. Thank you for the reply. Just a little earlier I contacted a local truss builder and I'm awaiting their response. Nice thing about that (other than not having to pay high price for an engineer -- I looked into that briefly) is that the local truss manufacturer knows the county inspection requirements and will supply the diagrams that satisify the code. Everyone's happy: the home owner, the builder, the county, and the truss manufacturer made a little money, too.

I'll look back here again sometime just to see if anyone else has any tips.

One thing is that I'd sure like to get in touch with some local builders capable of building this for me.

Ed

Hi Edro,

My suggestion is to use more conventional methods to achieve your end goal. The proposed design may work, but it is not familiar to most builders, inspectors etc. DoRight suggested trusses. Look at "attic storage" trusses. They provide headroom and knee walls.

Two more suggestions:

1) Balloon frame the walls. The spread load is handled by the floor joists tied to the outside walls and supported by the let in band (rib band).

OR

2) Install a ridge BEAM. That is a beam sized appropriately which the rafters "hang" off of. The ends of the ridge beam have to be supported by posts that bear down to the foundation either in a straight shot, or buy continuous load path through headers etc.

The collar ties as shown in the drawing (in the upper third) are designed to resist uplift, not any spread load.

Good luck with the project.

I do not mean to revive an old thread, but I have almost the exact situation as EdroRo. The only difference would be that building dimensions are a little bigger (20' span instead of 16'; higher clearance to collar ties but still 12-12 pitch) and the walls are balloon framed instead of knee walls. What was the resolution?