As y’all might recall from my ramblings last year, a big variable in Scouting Pinewood derby racing is weight placement. Obviously you want to weigh 5.0001 oz, but where to locate it?

Weight high and to the rear gives the most “fall”, and consequently the biggest gravity engine. But, if the track is bumpy, the low front axle weight makes the car hop and track poorly, bouncing side to side on the center guide strip, and scrubbing off speed.

Last year, after middling success with a “front-weighted” car, the year after a “rear-weighted” car, my daughter said, “we just need to make the weight moveable!

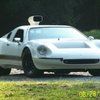

So, here is this year’s “weight-jacker” design. (12) 1/4-20 square nuts make up the major portion of the weight. They are located on a captive piece of all-thread, which has a slot cut in the end.

You reach through the rear washer with a small screwdriver, spin the all-thread and move the weight location to where you get the best speed for a particular track.

Race is Tomorrow (Sat) at 9; be crossing your fingers for her!

Edited 11/10/2006 9:12 pm by McDesign

Edited 11/10/2006 9:13 pm by McDesign

Replies

Awesome. Good luck tomorrow. My son and I will be racing in December. If it works we'll have to try it, after paying the appropriate amount to cover the intellectual copyright costs of course. :-)

Constructing in metric...

every inch of the way.

I've talked with the car owner, and she's decided the technology should be public domain. Have at it!

Assuming we do well tomorrow, that is!

Forrest

Nice technology.

Do they allow "dry lubrication", if so try TDL (teflon dry lube)...unless they specify "graphite only" in the printed rules.

Good Luck.

I slapped on some graphite I had - rules just say "dry" Maybe I'll see if someone's got some of that "TDL" tomorrow.

Forrest

With "dry" in the name they should permit it...this year. ; )It is fantastic stuff...worked so well on a double hung window I tuned up that the weights kept opening the window on their own when someone walked across the room...kinda fun, step on that one floor joist and up goes the window. Should be the ticket for your wheels.

I hope that thing has restrictor plates on it.

Neat idea. I remember when I was in the Pinewood Derby (40 years ago!) one year I put the weight towards the center/front part of the car and did pretty well, but in the car I built the next year I put the ballast in the rear. That second car didn't do nearly as well. After the competition was over, I ran the car down the track backwards and it seemed to run faster.

For ballast, I used some of my dad's lead bullets, set into the body so they stuck out like exhaust pipes. :-) Maybe it wasn't the fastest car but it looked cool...

Now that is pretty cool!!!

couple years back i made a pine wood derby car for my little cousin.

I went crazy with the thing, more from astetics than performance.

I made the car look like a formula one car. I made little fins for it and side panels that i glued on to create the body shape.....I started with the basic block that you but and sent it through the table saw to get the basic shape started, then just kept going..

He didn't win any races but didi get best of show for how the car looked.

Now if i could just figure out what the heck i didi with the photos i took of it i could post them...

Anyway best of luck with the racing!!!! let us know how you do.

Raymond

Good stuff! At the county fair here they have a race called the Zucchini 500. You grow your zucchini, make a race car out of it, and then they set up a gravity track on part of the skate park. My buddy Mark made a car for his sweetheart that won this year. I think he used skateboard wheels and a lead sash weight. This is a MAJOR event at our fair... better to have the winning car than the blue ribbon steer.

I've helped a friend with a few for his son... a good friend was a judge and a major event and he relayed a few key things he saw... and he's pretty sharp..

the fit of the wheels to the axle is critical... all 4 wheels have to be dead on in the same very square direction... and the winners all have very round wheels with only a razors edge on each wheel make'n contact with the track... when you use the dry lube make sure you lube the outside of the wheels where they might make contact with the edges of the track...

good luck

p

When I was a cubmaster we always gave the dads a car to build as well as the boys. the boys had to build theirs alone with only verbal instructions from anyone else. The dads were free to build theirs as they pleased. If no dad was around for a boy, then one was given to the mom or to her designate. Some dads wound up building 2 or 3 as designates.

One thing I always did was to turn the plastic wheels down on my lathe so they were running on a knife edge. Seemed to always work too! I didn't reduce the diameter of the wheels, just their width. Of course, lots of graphite in the wheels.

Our pack had two identical tracks for running.

That meeting was always the highlight of the year! Still brings back fond memories to me and to my sons.

PlaneWood by Mike_in_Katy (maker of fine sawdust!)

PlaneWood

Been There...Enjoyed That....

What a wonderful experience..80 (2-packs) Cubs all racing ..Dads on their own track ....kids on their own...worth all the hassle!

Lot's of awards and trophies.....what an ego boost for the boys!

No losers....all winners!

.........Iron Helix

I'll never forget the year we had a young man that was very underprivileged, no home support financially, emotionally, nor in the way of time or encouragement. He had missed some meetings where we all helped work on the kid's cars.

He came a little late on the big day, brought out his "kit" that was now just the block of wood with the wheels whacked on !

Son of a gun ALMOST won ! He was in the last couple of elimination runs. He was grinning from ear to ear, and took home a small trophy.

That's the kind of boy that Scouting is best for - the ones that wouldn't have those experiences otherwise.

By the way, my son had his Eagle Court of Honor three weeks ago !

Greg

My son is an Eagle Scout and a Senior at Univ of Tennessee now, but we had some great fun building Pinewood Derby cars back in Cubs. I used to help him do all the axel polishing, wheel truing, graphite application, etc., and found that there are enough variables in the track, etc., that no amount of "dad interference" really made that much of a difference in the outcome.

One of my fondest memories was of a race back in Mississippi where all the dads except one had plenty of involvement in the car construction. One kid, whose dad was a very busy doctor, completed his entire car without any adult help. He cut it to shape with a handsaw, used minimal sanding, sprayed it canary yellow, nailed the wheels on as they came out of the kit.......and blew away every car in the competition. Don't tell me there wasn't Devine Intervention involved here....and how appropriate for a kid to do it all by himself and win the championship!!

Roger

My experience is like yours. Most the other kids came in with these souped up dadmobiles (no outlaw divisions back then). I cut mine into a basic triangle, drilled holes through the side and filled them with cut off framing nails, slapped on the ugliest striped paint job (no tape, freehand to the best of my ability as a kid, which wasn't pretty) and came in second place. #15 has been my lucky number ever since and the pride I had in doing my own work far outweighed any other reward. It's kind of funny what stays with you over the years.

I love the outlaw/fundraising angle now. Let kids be kids and pound something together, and let all the adults whose fathers did it for them get a retry (or a first try).

Good ideas so far.I was the head of my son's den when he was in Cubbies, so I'd hold on to the kits and have a "buildfest" over my house. That was the best way to make sure that the kids did more of the body work than the Dads.My son did all the body work on his cars, and they always were unique. One was a simply painted race car with a leggo man stuffed in as the driver, one was a slice of pepperoni pizza. One was cut to loook like waves breaking on the water and he had a "surfer dude" surfing the curl of the wave. His last one was simply a wedge with rounded edges and he burnished the body with graphite.I do have to 'fess that I did work on my son's axles and wheels.He had great luck, winning twice and coming in second once. He missed the Derby one time (rescheduled) because we were on vacation overseas.Tips:

1) When you get the block of wood, turn it upside down and use a square to make sure the pre-cut axle grooves are perpendicular to the edge of the block. If they're not, flip the block over and cut new grooves in the "top" and waste the original grooves away when you shape the body.2)weight distribution. They usually have a weigh-in, have your car slightly heavier than 5 and take weight off to nail the maximum. You don;t want to show up slightly light, have your car accepted light, and run lighter than the other cars. Distibution? I found that having the CG 60% between the front and rear axles ran fastest.3) Aerodynamics? My son's cars were never sleek, with the exception of the last one that he simply rubbed down with graphite. He had driver's sticking up, slices of dowel (pepperoni) hanging here and there...even teh "surfer dude" standing tall on top of the car...yet he still won. Drag (or lack of) has to be worth something, but his cars always ran well.4)Axles: I'd chuck the axle point first into the drill press and turn the drill on. Using a fine file, my son would touch it to the sides of the axle and the underside of the head to take off any metal burrs.5) Wheels: Same, chucked in the drill press then sandpapaer was lightly rubbed against the spinning wheel, rounding the wheel and taking the embossed designs and ridged mold marks off the wheels. Smooth the insode of the wheel that touches the nailhead of the axle.6) Load the axles with graphite and mount the wheels. Run the car on the floor to make sure it tracks straight. Someone mentioned raising one of the wheels up slightly. We never did that, but a lot of others did.7) Possibly the hardest one to do. After the car is tuned, try to convince your kid to not play with it! AFTER the race he can play with it and have a demolition derby with the other kids' cars. Unless he wins the local race and goes on to the regionals, that is.Remember to relax and have fun. It's a great way to hang out with your son.I like that weight on the threaded rod that is adjustable. Very clever. Do remember though, no alterations to the car are alolowed after it's been registered.Mongo

We also had nail driving contests for the Weblo scouts. Set a short log on end (one for each boy), start a nail, and whoever got theirs all the way in first won. It was hilareous!

As a Scoutmaster, I once had a folding lock-blade knife fold on me and gash my finger pretty good. WELL, you think I didn't catch H E L L for that! The boys said I had to complete safety training again before I could use any tools! I did, and all was well.

I had an award on the campouts to whomever passed gas the most. It was a hansomlly carved wooden plug on a lanyard. Was called the "Chief Thunder Butt" award. It was most usually won by a dad or a leader.

During my 3 years as a Scoutmaster, we went on a campout every month. The coldest ones were the ones most remembered. Boys learned pretty fast how to set up camp when it was freezing rain and dark.

PlaneWood by Mike_in_Katy (maker of fine sawdust!)PlaneWood

The trick is to actually install three of the wheels perfect (two fronts and one back) and install the fourth back wheel higher than the others so it doesnt touch the track (adjust your weight so the three wheels sit flat) Make sure the weight is exactly at 5 and lube with graphite and you will be in good shape. Taking one wheel out of the equation reduces enough friction to beat the other cars. Been involved with scouts for years - this always works well. Infact, usually the people incharge of the race will feel sorry for your kid, thinking that the car is put together crappy since it doesnt sit flat.

Yeah! weird Karma - just heard about this in "my" other forum (hot rod Cadillacs) literally 5 minutes ago!

This year we couldn't test before the race and adjust the weight distribution; she won 4 races and lost 2, the last time to the eventual winner, a loaf of bread. Much fun was had by all!

Next year, for sure we'll be three-wheeling it!

Forrest

Yeah, give it a shot - I'm pretty sure there are whole web rings out there devoted to this. I think there have even been a few engineering PhDs on this subject. One year to test the track for alignment after it was set up I took the basic kit, assembled the wheels into the uncut block, and to get the weight to 5lbs I drilled a number of drywall screws a 1/4" or so into the top of the car. So I ended up with this block with 20 drywall screws sticking out the top and it actually beat about 90% of the cars there. I also noticed this with my sons car when he glued parts of these lead figures to the top and didnt really need to add any underside weights the car did very well.

Cool idea. Our pack this year is having an "outlaw" division. Open to any adult or older sibling that wants to participate for a $10 entry fee. Doubles as a little fund raiser and hopefully help the boys cars be the boy's cars and not Dad's.

We race on Saturday morning and set the track up the Friday night before. The Outlaw races will be run Friday night after the track is set up so as to not take awy from the boy's races Satrurday morning.

We are still working out the outlaw rules and limits. Sticking to 5oz. but may allow non "kit" wheels and axels.

I plan to drill pilot holes in the axel slots with the drill press at an ever so slight angle to give the the whells a bit of camber, thus running on the outer edge.

We run in January so keep the tips coming.

Sounds like fun - I love the "outlaw" moniker!

Sounds like it's for the guys who aren't "loyal, helpful, friendly, courteous, kind, obedient . . ."

Forrest - disloyal, unhelpful, unfriendly, rude, mean, disobedient . . .