Anyone have any experience or ideas on installing metal backsplash. Customer has a 4 x 8 sheet of brushed aluminum that they want installed over drywall. Don’t know the gauge but I’d guess it was about 1/64th thick. I guess I’ll rip 18″ strips with a router. Cabinets and granite backsplash will mount over it. I suggested mounting it to some form of substrate because material is so thin that any wall imperfections will telegraph right through, but they want it mounted directly on wall. What kind of adhesive can I use to mount it?

Jim

Replies

I would use a sheet metal shop to do this. They can make up a hanging strip like a small hat track rail and hem a lip to hang it or solder some clips to the back of it. Thermal expansion will be hard on glue joints but If I had to "glie" it I would probably use an adhesive caulk for the flexable properties.

Welcome to the

Taunton University of Knowledge FHB Campus at Breaktime.

where ...

Excellence is its own reward!

>ut they want it mounted directly on wall.

Directly to the framing? I wouldn't. I think they'll regret that--and you'll get a callback--the first time they bump something against it and they see the dent at the edge of the stud.

If you install your granite backsplash over the aluminum you better make sure your wall is straight along the backsplash, otherwise you'd get an unsightly caulk line along the granite backsplash.

Coz,

Here's one I did behind my cooktop. I did it with 0.040" T-304 stainless. I'd definitely never consider aluminum. Stainless is WAY more rigid and corrosion resistant.

Held in place with hidden nails and a little silicone. BTW, if you have no prior experience working with stainless, leave it to the pro's. It work hardens in a flash.

Jon

This is a 4 x 8 sheet of brushed aluminum. Cust picked it up at a counter supply (formica) distributor. They want to apply it directly to the dry wall. I suggested contact cementing it to a 1/4" substrate and then to wall because the plyable nature and thin gauge of the aluminum will telegraph every bump and joint in the drywall, if applied directly. They want to apply it directly to the drywall to avoid building out wall any further. I pointed out that undulations in the wall will result in large gaps when granit back splash is installed but they say they can live with that.

Any ideas on what type of adhesive to use to get it to stick to the drywall? Silcone? Flooring adhesive? Tile mastic?

Coz,

If it's only .0156" think, contact cement, but if me, I'd still would walk away from this one.

Jon

I'd walk too , if they don't want to hear your suggestions on how to do it right, then don't be part of doing it wrong.

( If they do want to listen - you're thinking right - laminate to a substrate)

sounds like I'd walk - good luck

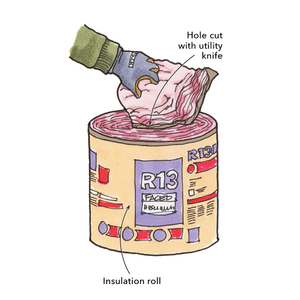

3M super 77..spray adhesive..work it just like contact cement..roll it out after ya stick it up with a paint roller and 3/8 ths nap instead of a J roller...easy does it.

edit ti say DON"T roll the glue!!! Roll the alum. after it's up!

View Image

Spheramid Enterprises Architectural Woodworks

Repairs, Remodeling, Restorations.

Edited 4/10/2004 8:47 pm ET by SPHERE

Coz,

Um.......Now I see attachments are vanishing too. Prospero definitely having problems. Anyhow's, here it is again.

Jon

i recently installed a "stainless" backsplash that was actually a laminated product by wilsonart. the metal surface was actually aluminum textured to look like SS

i cut 1/4 flooring underlay to fit precisely(cabinets and countertop were in place) and laminated using latex contact cement then fastened the laminated panels with "no more nails"

aluminum can be worked with carbide tools, real stainless? i doubt itcaulking is not a piece of trim

Take your sheet metal to a countertop shop and have them laminate it to a sheet of 1/2" MDF. Cut out a horizontal strip of drywall in the area(s) you want the metal. Add blocking so that you can screw the newly cut edges of the rock and also attach the sheet-mounted metal. Put the fasteners where they'll be covered by cabs and granite.

Whether or not you use aluminum is up to you. I wouldn't. I also wouldn't attempt to laminate metal to drywall--it'll show every contour of the drywall and look like hell. It'll even show the areas where you spread the glue too thick or thin. Guaranteed headache. If your customers won't listen to your expertise you need to refuse to work for them, or else get some kind of waiver allowing you to get paid for work that doesn't turn out.

I'm curious about why they want to use it for a kitchen since it is such a filthy metal.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

"I also wouldn't attempt to laminate metal to drywall"

David,

I agree about the "laminate" part. But as my pics show, 0.040" T-304 stainless is quite rigid, and IMO, makes for an excellent low cost, no maintenance backsplash. I think I paid $60. for mine new from http://www.onlinemetals.com

View Image

Jon

Edited 4/11/2004 9:56 pm ET by WorkshopJon

That's a sharp looking kitchen, and I agree the steel looks very flat. I was trying to imagine the OP wrangling a piece of .015 aluminum into place over a wavy piece of drywall with a big tape joint in it. It would crinkle as soon as you applied pressure. Stainless is the way to go, and I hope he persuades them.

David,

Thanks for the complement.

"Stainless is the way to go, and I hope he persuades them"

This is one of those situations where the cost of the material is a moot point. It's all labor. BUT, stainless is a tricky mtrl. to work with. I've been working with it for over twenty years, and every now and then still I get burned. Like I said in a prior post in this thread, it can work-harden in an instant. When that happens, all you can do is burn it, or grind it.

Tricks include aggressively pilot drilling, then opening up holes that will be large. Aggressive (min 0.005") machining. Use of coolants with minimal lubricity (water NOT OIL!!!!). Don't even consider using anything other than a high quality freshly sharpened cobalt drill to poke a hole, (and forget about carbide for holes, it just isn't sharp enough{for drilling}).

IMO, rely on a viscous, troweled adhesive to hold up a sheet of SS. SS over 0.040" shouldn't show wall imperfections. Use nails as a back-up and to hold the sheet in place while the adhesive sets up..

Jon

For lengthwise and cross cuts, use a grinder.

Stainless is the only way. Aluminum will oxidize, it will stain, it will scratch, it will dent (you said it is thin), they will be pulling it out. It is much softer than SS. If you don't want to walk have them sign a waiver, that might get the point across. But under no circumstance would I apply it without a backer, drywall is fine. They don't want to loose any space with "thin" sheet? Sounds like a designer. What happens if they want to hang something on the wall? Find a restraunt metal fabricator in your area for the SS and they will cut and bend it for you.

Have applied SS in many MacDonalds. Use silicone as adhesive and around joints. Yes, SS work hardens very quickly, do not apply too much heat. On more than one occasion have spent 30 minutes and 3 new bits drilling a 1/8" hole. One way is to cycle the drill on and off quickly, this works well and lets heat discipate, asked around after going through many bits.

Since they bought the Al at a laminate supplier isn't it the stuff that is backed with the brown backing? They bought it, let them return it. If it is the stuff I am thinking about it is not intended for the application (Obviously) and also expensive, arount $200 - $300 per sheet.

Al custs well with a fine tooth carbide blade, use a lubricant. But never try this with SS.

Coz,

Thought I might add, stainless can be made to look similar to brushed aluminum. There are ways to dull down the sheen.

Jon

COZ , I just installed a 30" wide by 36 " long stainlesss backsplash piece behind my stove. I used a piece of 1/4 " maple/birch plywood as a substrate. I cut out the plywood to fit my application perfect because as you know , nothing is ever totally square. I also installed a pot filler above my stove as well so I had a 1 1/2 " hole drilled in the middle of the backsplash as well. I brought the plywood down to a sheetmetal fabricator and he fit a piece of 20 gauge stainless perfect . Even wrapped the 1/4 " edges nice.

Anyway ,I attached the plywood to the wall with screws then liquid nailed the stainless to the plywood. Using clamps and scrap boards I could hold the metal in place unitl it dried. Plus my flange from the pot filler helped hold it in tight as well.

It turned out slick. And only cost me about 100 bucks in material.

I did the same thing in my kitchen- used thin sheet ss and "burnished" it myself wiht some wet sandpaper. I used a caulking tube of liq nails and it has held really well, just be sure to get it in the right place the first time

Thanks everyone for your input! I sent my customer a link to this thread and hopefully with all of this collective wisdom they'll be able to make a more informed decision. I especially think that the point about the al being prone to oxidation and damage is really key.

Jim