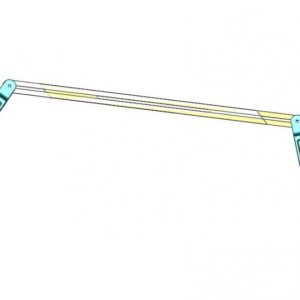

I have been searching for a tool to help template out of square stair treads. Since I could not find a tool, I decided to draw one up. Tomorrow I will build it. Basically it is two bevel squares with extra long blades, bolted together. This tool will get me an accurate width and accurate angles on both sides. Here is a picture of my design. Has anyone seen one of these? Any comments? Maybe I could market this???

Edited 3/9/2009 9:55 pm ET by DTHA

Edited 3/9/2009 9:56 pm ET by DTHA

Replies

I use 2 pieces of plywood scraps shaped like triangles with slotted holes. the piece in the middle is similar to yours.

There are two different stair bevel gauges advertised in teh pages of FHB.

if I were making one up from Bevel squares like that. I would join the wood handles to a center shaft with sliding holes, then the metal bevel piece would be able to slide to depth for various tread widths

Welcome to the

Taunton University of Knowledge FHB Campus at Breaktime.

where ...

Excellence is its own reward!

Actually, this design allows the adjustment you mention. The slotted holes in the metal blade are meant to allow this adjustment...

I see that it does, but I would rather mark cuts to the metal slide bar than to the wood handles, and those handles will fit to t he front edge of the tread for alignment if reversed as I said.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Yep. Collins Tool Co.

Andy

"Never try to teach a pig to sing. It wastes your time and annoys the pig." Robert A. Heinlein (or maybe Mark Twain)

"Get off your dead #### and on your dying feet." Mom

"Everything not forbidden is compulsory." T.H. White, The Once and Future King

There are some commercial jigs but they aren't cheap. I normally use a 1x10 piece of pine, scribe, cut and check the fit. It usually holds good for a few treads if not most. Once in a while, the cuts aren't perfectly straight. If the next tread is tight, it often forces the skirt on the preceding one to open up. I just measure what's missing on my template if the stairs are not open on one end. You can also adjust the risers by using it as a straight edge and check to see if the stringer blocks are level. It helps if your template is as wide as the tread or close. One tip, leave the bottom tread loose, just in case you drop something down the chute.

Beat it to fit / Paint it to match

""One tip, leave the bottom tread loose, just in case you drop something down the chute.""

You too huh? Funny story about that .

I did lose a small pry bar down a stairs because I dropped it into the "chute" and didn't want to undo all the work to retrieve it. Couple of jobs later I am demoing a stairs and lo and behold what is revealed but a small wrecking bar, stamped "Sheffield of England", I got back better than I gave to the stair gods.

They can't get your Goat if you don't tell them where it is hidden.

I lost a baseball down a sidewalk storm drain some 50 years ago. We managed to remove the iron grate to get down in. I found a Stanley crow bar down there and I still have it today. Of course, there's more than one of my lost tools hiding in a house I've built.Beat it to fit / Paint it to match

I usually work top down..

eliminates that problem, and if I can set up at the bottom it lowers the chances I'll damage something in the process

How do you attach the riser to the back of the tread if you work from the top down? Do you balance on the center stringer points and hope you don't slip or one doesn't break? Considering how much we go up and down, cutting and fitting pieces, climbing back and forth on points ain't for me. I'm a baritone, think I'll try to stay that way.Beat it to fit / Paint it to match

Hi Barry Tone!I'd imagine he has temp plywood treads screwed down for construction phase and takes them up a couple at a time while installing the finish treads. but top down does feel backwards to me.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Here's one that made it into FHB -- they even paid me $150!

Dear FHB,

I enjoyed Bruce Abernathy's article on cutting stairs (FHB #168, pp. 76-80), and I'll file away that tip about cutting the stringers for the thickest possible tread. It's not as pretty, but shimming them up later sure beats having to cut them down.

I use a stair gauge similar to the author's, but I have made two important modifications. First, the length on mine is adjusted by sliding the jig's 1x1 arms through a short piece of rectangular aluminum tubing which I tapped to receive a thumbscrew. To prevent the thumbscrew from chewing up the 1x1s over time, I slipped a thin aluminum strip inside the tube and bent the ends over so that it doesn't fall out.

This jig is quite a bit quicker to build than the routed-slot system, but the best part of it is the ends: I use short (approx.15") lengths of a standard carpenter's door/plywood cutoff fixture, or "shooter board" (FHB #166, p. 124). I cut the ends at a slight angle to ensure that it will fit into out-of-square corners. To use the jig, I extend it between the stringers as in the article, but instead of having to trace the jig onto the tread, I simply clamp it to the tread, and run my circular saw over it. With a standard sidewinder, the right-hand cut, as you face the stairs, will be made front-to-back. The left-hand cut, though, is back-to-front, so I wrap the nosing with masking tape to avoid tearout.

This jig is easy to modify, too: use longer sticks for wall-to-wall shelves, for example. And the adjusting tube can be used without the cutoff jig. Mine actually spends more time living on a pair of plain 8' 1x1s, which are handy for obtaining awkward inside measurements such as when I'm putting up crown molding solo.

AitchKay

I just might have to try making one of those. Usually mine don't last that long (as little effort possible invested doesn't help longevity) nor do I try to keep them but this one might change my attitude.

Iv'e built this jig out of MDO and some knobs I got at the hardware store.

Wayne

I don't think I can recall any self-made jig that has had so many variations and iterations. I think it's truly amazing, and no doubt that they all work, or readers wouldn't be posting them... I think it's great!!

At its most basic level, capitalism offers people the freedom to choose where they work and what they do � the dignity that comes with profiting from their talent and hard work. � The free-market system also provides the incentives that lead to prosperity -- the incentive to work, to innovate, to save and invest wisely, and to create jobs for others.� -President George W. Bush

In other words, free-market capitalism is the best path to prosperity.

If I'd had the new-style Festo rails, I'd have used short sections of that: it's got a second channel that you could bolt the telescoping arm into, unlike my first-generation Festo rails.Now that would be tweaking!But either way, the jig is extra-handy because it's an actual cutting jig -- you don't even have to mark the cut.AitchKay

HK

I'm going to make one like yours.

Ron