Started wreath handrail class today

Today I started the first class on wreath handrails. The difference between reading the books and having someone explaining the process is quite a gap.

First class is on how to make a 90 degree turn at a landing.

Edited 1/16/2009 10:48 pm ET by mathewson

Edited 1/16/2009 10:49 pm ET by mathewson

Replies

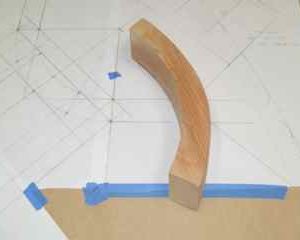

Here are the pics of the wreath

Wow, I'm envious. There is nothing like that here in Oklahoma.

Did you have to do the layout as part of the course? What books if any is the class using for the work?

Sometimes courses are also offered by internet although this might be to difficult to be done.

Any way keep the photos coming I for one am very interested.

Just A Guy With A Hammer

Jagwah,I hired a local designer/stairbuilder to teach me wreath handrail construction. The scope of the class is of my own choosing. For the progression of projects I am following George Ellis's book on handrailing.The way things work, I present a situation for a wreathed turn. In this case a simple 90 degree turn. I outline what the rise/run might be, size of landing, etc. as if this were a job I was looking to build. He draws it up on an auto-cad program to look at. Boy I've got to learn Auto-cad!We then go to the table and draw it out full size as if the auto-cad drawing didn't exist. From there it is to the bandsaw & make to piece.Everything at the moment is done out of chunks of cedar I had laying around. So it is left just as it came off the bandsaw. As things progress and it is time to dress up the faces I'll move to popular

Very interesting, I have a local millshop that does such. The person who owns this shop and I have talked many times. I never thought to commission my own class. For that matter maybe offer to work a week or so for learnin'. Maybe trade a bit of labor for the lessons.

Thanks for the info.

Just A Guy With A Hammer

I'm usually just lurking but always enjoy your threads, I'm doing more and more stair work and am enjoying this one so far, I've been studying the Audel's Carpenter's book synopsis of making these wreaths and bends for years but never had a job to attempt it on yet..maybe this will inspire me to just start making them up on the bench as practice. Keep up with the pictures if possible.

I just took a class on laying out eyebrow roofs. Same feeling you had, it is much different being instructed vs using the net or a book.

View Image

Billy's eyebrow class

that was cool - I have it in my favorites now"...craftsmanship is first & foremost an expression of the human spirit." - P. Korn

bakersfieldremodel.com

The class was very cool. Pretty intense, but Billy did an amazing job teaching. I feel that I can lay one out and cut it w/out too many issues.

He taught us how to draw the eyebrow, develop the layover valley and backing bevel, and also the inner valley for the ceiling line.

Now if we just had a customer I could talk into letting me do this . . . .

Thing about it is that it would be easier in "real life" because you can snap out and transfer isn't as tedious. Plus you can use power tools like a chainsaw instead of a draw knife. :-)

I will attempt to explain the process as we do these classes. The method which is used is slightly different than what I've seen in the books I have, basic info seem to be very similar.The biggest difference in this approach seems to be that the inside & outside lines of the handrail are used instead of the centerline.A right angle is drawn, this corresponds to the inside of the handrail. The angle is bisected into a 45 °, this becomes the center line and a arc is drawn at 7 1/2". From there each 45 is bisected into 22.5°'s and lines drawn.The inside radius of this turn is 7 1/2"

The handrail is 2" wide making the outside radius 9 1/2"A line is drawn from the 2 tangent points of the arc connecting them. This line is perpendicular to the first 45° bisector. It is from this line that perpendicular lines are drawn to the next drawing.To begin the second drawing a line is drawn perpendicular to the center line . The triangle which can be seen is formed by raising on side the height of the riser. Lines are now drawn perpendicular to what is now the Hypotenuse.The pic attached if poor and I don't know if the lines will show up well. The distance that the points are made along these perpendicular lines are the same distance as the radius line is from the line connecting the 2 tangents in the first drawing. It may be easier to see along the center line. The distance from the inside radius (7 1/2") and the perpendicular line connecting the tangents is the same as from the hyp of in the lower drawing and the inside of the handrail.When all the points are drawn for the inside & outside of the handrail a thin piece of fiberglass stick is bent to touch on all the marks and lines drawn. That is now the shape to be drawn on the blank. The blank is mounted on a pitch block for bandsawing. The pitch block is NOT a standard pitch block. It is not the rise and run of the stair. It is the rise and the stretch out of the radius. In this case it is 1/4 of the circumference of the outside of the handrail. That is 9 1/2" x2πr= 14 15/16"Mount the blank to that pitch block and you will now have the correct twist with 90° sides as well as the plumb cuts for joining to the straight handrails.Leave the blank mounted to the pitch block & use a large disk sander for the outside sanding and a spindle sander for the inside. From there gauge handrail thickness & bandsaw.Clean up bandsaw marks. You are now ready to profile the piece- or so I'm told, I haven't done that part yet.

Edited 1/17/2009 8:47 pm ET by mathewson

Keith,I had to look around for those drawings. Here is one that's like the one you are doing. This is for a quarter turn stringer.http://www.josephfusco.org

http://www.constructionforumsonline.com

Great info Joe- thanks.Today was the second day of layout. It is a 4 step winder with a wreathed stringer and wreathed handrail. The wreathing of the stringer makes for a very compact yet graceful alternative to a 3 step straight winder.Today I started the cutting of the handrail tomorrow will be doing the stringer. If time permits I may be able to profile the faces of the rail as well.Even though this has been extremely enjoyable to learn, nobody is building anything to put it to use on. I feel somewhat like a kid who gets a battery operated toy for christmas and no batteries, and being christmas no stores are open. pics attached

Keith,The work looks excellent. I know what you mean about having no batteries. Once you start this it's like you want to make about fifty of them ;-).http://www.josephfusco.org

http://www.constructionforumsonline.com

Keith,One question I had but didn't ask it, was what technique did you use to layout the face mould.

Did you plot the points and use a batten or find the major and minor axis's and use a trammel?http://www.josephfusco.org

http://www.constructionforumsonline.com

Joe,I used a batten to bend to the riser corners.A standard rise/run, stretch out of curve/run and a standard rise/run. From that measure up off a perpendicular line to get the measurements to transfer to the handrail blank on the pitchblock.This gave the bevel cuts as well as the curve.As a side note- I'm somewhat surprised that there wasn't more interest in this thread. There were a few key things which once they were explained, the rest became fairly straight forward. With the pic of the drawing you posted yesterday, some work in process pics containing explainations of the steps I feel anybody on this site could readily produce one.

Sold a wreathed handrail job with a wreathed stringer today. It is for a builder I've done work for before so he trusts me, lets hope he still trusts me after this one.As I was practicing laying out & cutting blanks it occurred to me that most applications are circular in plan view. Given that it would seem that when the blank to be cut was placed on a pitch board the cutting & sanding could be done with a circle jig. The person who is instructing me had never tried it, but when we looked at it, it seemed plausible. Tomorrow I will try cutting on using that method. If it works I'll try to make one for an ellipse jig as well.The other thing which seems possible is that the bevel cuts, once the fall-line is laid out can be accurately cut by pinning the face of the wreathed blank to the table of the bandsaw. Since both faces are parallel from the circle jig on the bandsaw it now needs squaring for the bevel cuts. I'll make a jig using a skateboard wheel to hold the face mold to the table. Has anyone tried this before and does it work?

Keith,That good news. I'm sure you'll do an excellent job.http://www.josephfusco.org

http://www.constructionforumsonline.com

Thanks for the encouragement Joe.I found that if the pitch block is glued to a piece of plywood a circle jig works well for both cutting & sanding. It gives very true sides without flat spots. In addition since the plywood represents the plan view it can be placed back on the drawing to check accuracy and draw in the plumb cuts.When making the bevel cuts the plywood base greatly helps to keep the blank 90° to the bandsaw blade. As long as attention is paid to staying on the tangent point it is quite easy to cut the bevel square to the faces.This reduces the overall time to make the piece considerably. The drawing only needs to be in plan view and there is very little handwork as well.