I am trying to bend black walnut piece (1.25 x 4.25 x 21) to a 13” radius, and my first attempt used the setup in attachment 1. The wood was air dried, and steamed at 212-215 deg F for 70 minutes.

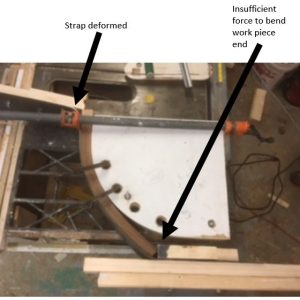

The result is in attachment 2.

If you have any advice on

a) how to salvage this work piece (i.e., can I re-steam it once I correct my setup?), and/or

b) how to modify setup to avoid the described failures, I would appreciate it!

Replies

There is a fair amount of steam bending content over at Fine Woodworking, but I am not sure how much of it is paywalled.

One thing I remember seeing there is to pre-bend the piece in the opposite direction and then make your bend. The assertion was that it really loosened things up and allowed easier/tighter bends.

Maybe I'm taking the drawing too literally, but with the supplied setup, I would expect that the pine block at the long end of the strap (with the 2x backing) would be torn off.

The metal strap is not likely to stretch much. The walnut under it, isn't going to compress much. When you wrap that around the form, the length of the walnut would have to compress as it is being wrapped about a smaller radius that the metal strap.

That also seems like a really thick piece of walnut to bend. Seems like most approaches are calling for 1/8 to 1/4" thickness of the laminations. Again it is the same problem as with the metal. The inner radius is going to need to be shorter that the outer radius of the board.

I don't think 70 minutes is long enough for that thickness and for walnut. I would at least double the steaming time. Maybe even triple it.

Also bend it to a tighter radius to allow for spring-back.

This is more of an art than a perfect science.

Frankie

I do more fine furniture than anything and if I were to do that, I’d slice that walnut in the bandsaw into 4 thinner pieces and glue it back into a bent lamination. If you took it down to 1/8” strips, you wouldn’t even need the steam.

To slice it into 4 thinner pieces and glue is the best way I guess