Steel support for cantilevered Granite?

Hi all,

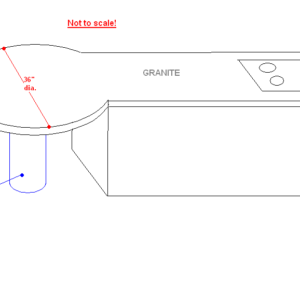

I have a customer that is replacing laminate countertop with granite. I won’t be doing the granite installation, but they want me to build them a 12″ diameter support column to reinforce the cantilevered portion of the island countertop (see attached drawing).

The granite company is also requiring an additional round steel plate to fit on the underside of the overhang, and I’m just wondering if anybody has any idea how these steel supports are likely to attach? I’m going to call the granite company and talk to them directly. But, as always, I’d love to hear what you all have experienced.

I’m hesitant to jump into working with steel, but if it’s just going to attach in a simple way then I can save them the trouble of hiring a whole separate contractor just to do that. Any experiences or insights to share?

Justin Fink – FHB Editorial

Replies

I did a kitchen a few years ago with a cantilevered granite breakfast bar. We had a local steel fabrication shopmake us up a bracket that mounted to the cabinet (with just barely enough knee room) and supported the granite. As I recall, the stone crew used an adhesive to bond the stone to the bracket. And they were VERY fussy, understandably, about the braket being absolutely flush with the cabinet top, and remaining in plane.

Fortunately, we had a good steel guy, and we put our best trim man (okay, it was me) on the install. Worked out well.

For your application, I'd suggest some sort of mechanism on the support pole that will allow for height adjustment and tweaking of the angle.

If this is on a concrete floor, glueing the pedestal is the thing, but if the floor is on a wood joist supported floor you might think about the the floor sagging with heavy weight of four people around the cantilevered section and thus unsupporting or pulling the supported piece down and cracking the top at the edge of the cabinet that supports the rest of the counter. I would be thinking about a triangle section bolted to the cabinet and angling to the center of the circle, then it all moves together. Might not look as good as your pedestal...unless those who know granite well would say that the granite will flex enough to not have a problem.

Kind of a large file there, Mr. Fink.

View Image

Are you asking about the connection of the steel to the column or the granite to the steel? I'm guessing with that kind of cantilever, the steel plate is going to be pretty thick (3/8 or 1/2" maybe, but the granite co would probably specify). In which case you would have plenty of room to countersink large wood screws into that plate that went into braces in the column.

zak

I'm actually wondering how the steel (which the customer is telling me will be 1/2") is going to attach to the cabinets. Until I talk to the granite shop, I'm getting most of my information second hand through the customer - it's like playing telephone!

What they tell me is that the existing cabinets need to be cut with a 1/2" dado along the top edge so that, when installed, the top surface of the steel plate will be flush with the top edge of the cabinets. I'm wondering how the plate will fasten to the cabinets, doesn't sound like the granite company is spec-ing any sort of angle bracket. It's frustrating, but I will hopefully call the granite company today and sort this out.Justin Fink - FHB Editorial

Look at it the other way around. The steel and granite are the least deflecting member, so you are actually attaching the cabinets to the steel vs. the steel to the cabinets.

Sounds like it is time to invest in plasma cutter and welder? More toys!!!

I don't get it- Why does the steel need to attach to the cabinets? From the drawing, it seems like the steel plate wouldn't come near the cabs at all -unless it's 36" diameter.If I understand the situation, the trick is not attaching the column to anything as much as getting the column/plate set at the perfect height, and level. As tomrocks said, you need to allow for adjustment onsite, as shimming will be required under the cabs and things will be less than perfect. I would use a threaded steel pipe, 3" or 4" diameter, close to the desired height of the cabs (minus 1/2"). with ####threaded flange on either end. You'll need to have the round plate fabricated anyways, so have them tack 3 short threaded studs to drop concentrically over the holes in the top flange (this can all be done in the shop).Now, you can take the whole thing back to the site. With the cabs shimmed and leveled, bolt the column to the floor and shim it perfectly plumb. bolt the plate to the top flange and use a long level to get it flush to the height of the cabs, making sure it sits flat and level itself. The height from the bottom of this plate is how high you will make your 12" "finish" column. This could be a nice length of 12" white pvc. Now you can remove the plate and flange, drop your 12" tube down over the steel, and screw the top flange down tight so it compresses the column to the floor (plywood blocks on the floor will locate the bottom). When the granite guys set the top, their adhesive will correct minor imperfections (remember, this part is cantelleivered). additional fastening won't be needed. Simple, but not easy!

p.s. one more detail- instead of locator blocks on the floor, use a 3/4" plywood disc under the bottom flange, cut to the I.D. of your column. You can screw the tube to this to preevent spinning, and it will help deflect any weight, which actually shouldn't be very much actually , because the granite is cantellievered.

Edited 4/7/2006 11:52 am ET by saulgood

Edited 4/7/2006 12:07 pm ET by saulgood

Saul,

First let me say: Really great idea to have a 3 or 4 inch threaded rod so that I can adjust it, then drop the finish column over - that's a great idea!

Let me clarify on the steel plate though. Because the cantilevered portino of the countertop will be about 36" in diameter, it will need more support than the column can provide. The underside of the 36" circular piece will have a 1/2" steel plate that is about 30" in diameter. This steel plate will support the granite overhang, and run back into the cabinets via a 1/2" dado along the outside edge of the cabinet top. Make more sense? ...this thing is hard to explain, imagine me trying to understand the homeowner!Justin Fink - FHB Editorial

It sounds like drilling and countersinking holes for screws in the steel plate will work fine over the column. As far as the attachment to the existing cabinets, I guess you mean the "dado" there will be 1/2" deep, through the exterior of the case, so you can project the steel through the cabinet side. That way, if you had the clearance above the nearest drawer, you could glue something alongside the cabinet wall so you had more to glue and screw to. That's going to be a heavy chunk of steel. If you can make an accurate drawing of the steel, it might be best to have the steel drilled for you at the same time as they cut out the shape.

zak

Yeah, I still dont understand why the column and steel disc need to be attached to the cabs. As long as its fastened to the floor long enough to stay plumb for the install, the granite itself will provide all the permanent structural support it needs. The adhesive will keep it snug, and the 30" plate will never be able to tip.Oh, wait- are they thinking that the steel will be a cosmetic part of this deal? I can see that... but you're talking about a huge difference in cost, weight and effort. It sounds like the archy got carried away trying to work with the plate. IMO, 30" is way overkill. A 20" disc would still leave only 8" of unsupported stone, and no one would ever see it. 1/2" plate at twenty inches will be pretty heavy - can you imagine working with a 30" circle with a, what, TEN FOOT rectangle hanging on? ridiculous. I'm sorry, but this is the kind of thing that looks good on paper to someone who won't have to worry about actually doing it.

This can be pretty easy.

How much overhang are they willing to allow?

On our jobs they would use 3/4" square tube steel.

It would be like a wagon wheel style construction with screws anchoring it to the column.

Do you look to the government for an entitlement, or to GOD for empowerment. BDW

I used steel bars to hold up my granite countertops. I had A sttel manufacturer drill screw holes in the middle for me and routed the depth in the wall. Then screw the in worked out great and leaves nice clean look. Hope this helps. Leave steel bars about 2 in from the end of each side of the granite.